Explore the working principle, types, and advantages of ultrasonic flow meters, along with their applications in various industries.

Understanding Ultrasonic Flow Meters

Ultrasonic flow meters are crucial devices employed in various industries for the measurement of the velocity of fluids. They provide a non-invasive method to measure the volume or mass flow of liquids and gases. These advanced meters operate on the principle of ultrasound technology and have distinct advantages over traditional flow measuring devices. Let’s delve into the working principle, types, and applications of ultrasonic flow meters.

Working Principle of Ultrasonic Flow Meters

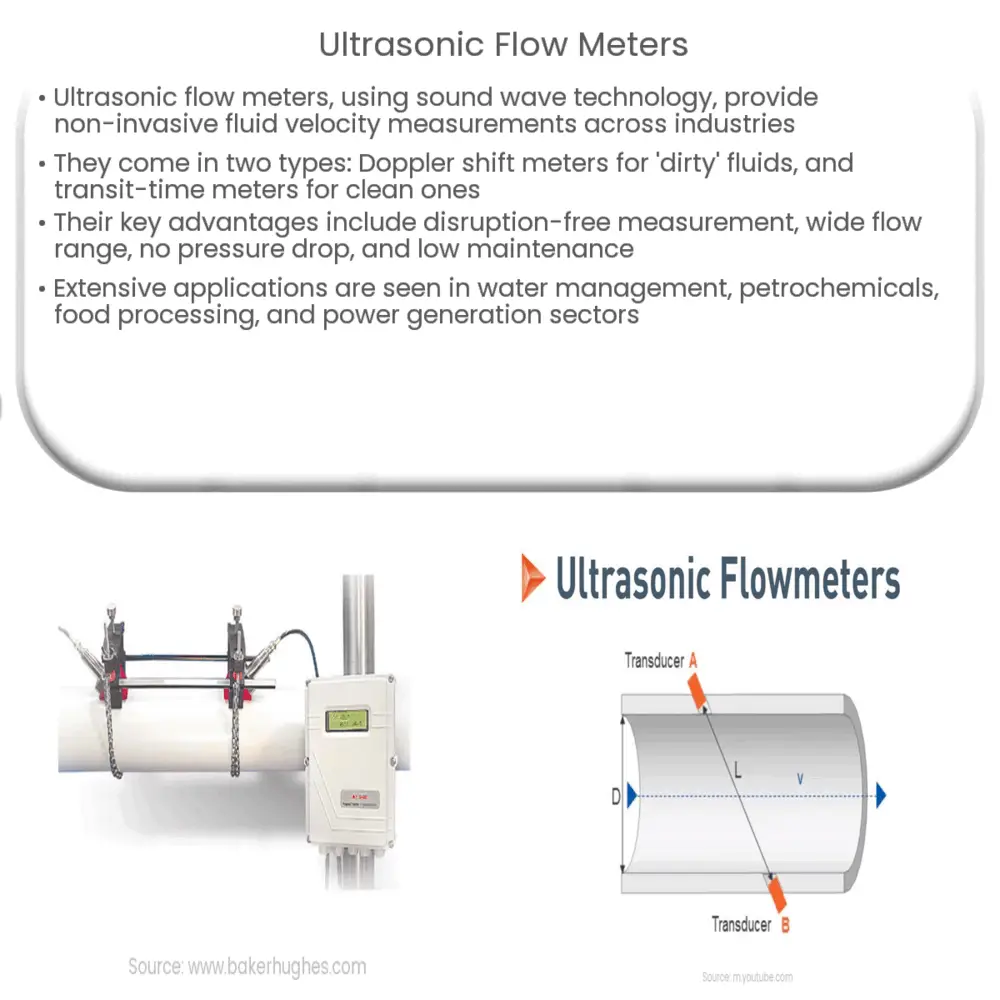

The basic working principle of an ultrasonic flow meter is grounded in the use of sound waves. These meters function by transmitting and receiving ultrasonic waves between transducers; the difference in the transit time of these waves is measured and used to calculate the flow rate.

- The flow meter sends an ultrasonic sound wave from one transducer to another. This wave travels with the fluid flow.

- Subsequently, the meter sends another wave from the second transducer to the first one, against the flow of the fluid.

- When the fluid is stationary, both waves travel at the same velocity. However, if the fluid is moving, the wave travelling with the flow reaches the other transducer faster, and the wave travelling against the flow takes longer.

- By calculating the time difference, the flow meter measures the velocity of the fluid, which can then be used to determine the volume or mass flow.

Types of Ultrasonic Flow Meters

There are primarily two types of ultrasonic flow meters: Doppler shift and transit-time meters.

- Doppler Shift Meters: These are designed to measure the velocity of ‘dirty’ fluids that contain suspended particles or bubbles. They work based on the Doppler effect, which describes the change in frequency or wavelength of a wave in relation to an observer moving relative to the wave source.

- Transit-Time Meters: These are used to measure the flow of clean, single-phase fluids that do not contain any bubbles or particles. As we discussed earlier, they work by comparing the time taken for an ultrasonic wave to travel upstream against the flow versus downstream with the flow.

In the next part, we will explore the advantages and applications of these ultrasonic flow meters in various industries. Stay tuned.

Advantages of Ultrasonic Flow Meters

Ultrasonic flow meters offer a range of advantages that make them preferable for a wide range of applications.

- Non-Invasive: As they measure the flow externally, there is no need to cut pipes or stop the flow, making the measurement process disruption-free.

- Wide Flow Range: They can measure extremely slow and fast flows, with high accuracy.

- No Pressure Drop: As there are no moving parts or obstructions in the flow, there is no pressure drop in the flow system.

- Minimal Maintenance: With no moving parts, wear and tear is greatly reduced, leading to minimal maintenance.

Applications of Ultrasonic Flow Meters

Thanks to their unique attributes, ultrasonic flow meters find wide usage in diverse sectors.

- Water and Wastewater Management: They are extensively used for leak detection, flow measurement, and chemical dosing in water and wastewater management.

- Petrochemical Industry: Ultrasonic flow meters are suitable for measuring the flow of different petrochemicals, including crude oil and natural gas.

- Food and Beverage Industry: These meters are utilized for hygienic flow measurement of liquids during food processing.

- Power Generation: They find application in the power sector for measuring the flow of coolants in power plants.

Conclusion

In conclusion, ultrasonic flow meters serve as indispensable tools in various industries for their high accuracy, non-invasive nature, wide measurement range, and ease of maintenance. Be it in water treatment, petrochemicals, food processing, or power generation, they play a pivotal role in ensuring efficient operations. While understanding their working principle and types can help users select the appropriate meter for their needs, continuous advancements in technology hold the promise of more sophisticated, accurate, and efficient ultrasonic flow meters in the future.