Explore the world of Surface Mount Resistors: their design, types, applications, advantages, and limitations in modern electronics.

Introduction to Surface Mount Resistors

As a fundamental component in electronic circuits, resistors are employed to limit current, divide voltage, and create specific signal characteristics. The specific type of resistor we will focus on in this article is the Surface Mount Resistor.

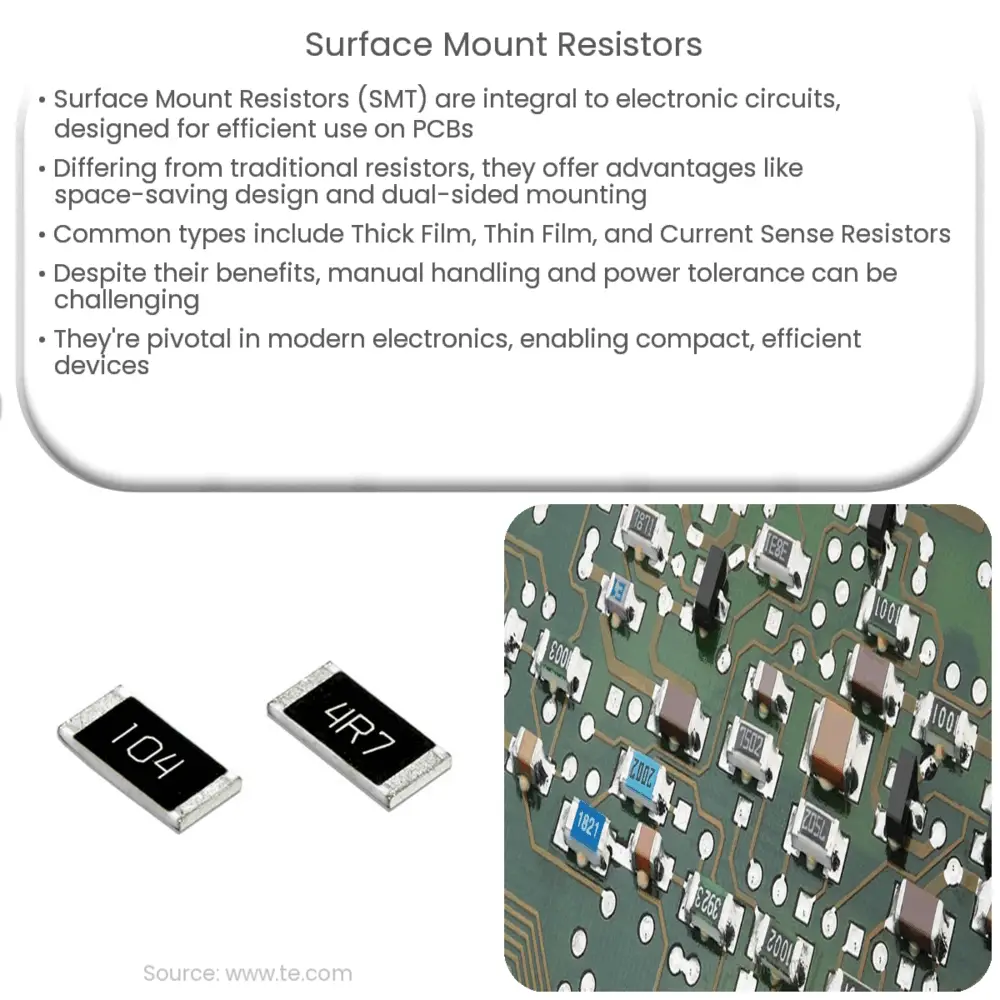

Surface Mount Resistors, also known as SMT Resistors or SMD Resistors, are designed for use on printed circuit boards (PCBs). Unlike their through-hole counterparts, these resistors are mounted directly on the surface of the PCB, hence the name Surface Mount Resistors. They are a key component in surface mount technology, a method that allows for more efficient use of space on a circuit board and has revolutionized electronics manufacturing.

Design and Characteristics of Surface Mount Resistors

The design of Surface Mount Resistors is significantly different from traditional through-hole resistors. Typically, an SMT resistor consists of a ceramic substrate onto which a metal oxide film, or resistive element, is deposited. This is then protected by a layer of glaze or epoxy.

The small size and lightweight nature of SMT resistors are advantageous in many applications, particularly where space is a constraint. The absence of long, protruding leads simplifies automated assembly, while the fact that they can be mounted on both sides of the PCB increases design flexibility.

Common Types of Surface Mount Resistors

Values and Tolerances

Just like other types of resistors, SMT resistors are available in a wide range of values and tolerances. The resistor value, measured in ohms (Ω), is typically marked on the resistor’s surface using a standard coding system, like the EIA-96 code. The tolerance, denoted as a percentage, signifies the potential deviation of the actual resistance value from the nominal value.

The choice of resistor value and tolerance depends on the specific requirements of the circuit in question. For example, a circuit requiring high precision would necessitate resistors with lower tolerances, typically less than 1%.

Advantages and Limitations of Surface Mount Resistors

Surface Mount Resistors come with several advantages over traditional through-hole resistors. Their smaller size allows for a higher packing density on the PCB, which can lead to increased functionality in a smaller space. Additionally, they can be mounted on both sides of the PCB, further increasing design flexibility. The absence of long leads not only simplifies automated assembly but also minimizes parasitic effects such as lead inductance and capacitance. Lastly, SMT resistors typically offer better performance in terms of speed and frequency characteristics.

Despite these advantages, there are certain limitations to consider when using Surface Mount Resistors. Firstly, due to their small size, they can be difficult to handle manually, making prototyping and manual repairs more challenging. Also, they are generally not as power-tolerant as through-hole resistors, which may be a consideration for high-power applications.

Applications of Surface Mount Resistors

Surface Mount Resistors are ubiquitous in modern electronics, finding use in a myriad of applications. You can find them in nearly all types of electronic devices including computers, mobile phones, automotive systems, medical devices, and aerospace technology. They are used for various functions like voltage division, current limiting, noise filtering, and creating specific signal characteristics.

Conclusion

Surface Mount Resistors represent a critical advancement in electronics, facilitating the development of compact, efficient, and complex electronic devices. The advent of surface mount technology has drastically transformed the landscape of electronics manufacturing, enabling more efficient use of circuit board real estate and a faster, more automated assembly process.

Despite certain limitations, the many advantages of SMT resistors such as their small size, light weight, and improved electrical characteristics make them an ideal choice for a wide range of applications. As technology continues to advance, we can expect to see further developments and innovations in Surface Mount Resistors, solidifying their place at the heart of modern electronics.