Explore the principles, types, applications, and maintenance of Pitot Tube Flow Sensors, along with their strengths and limitations.

Pitot Tube Flow Sensors: Understanding The Basics

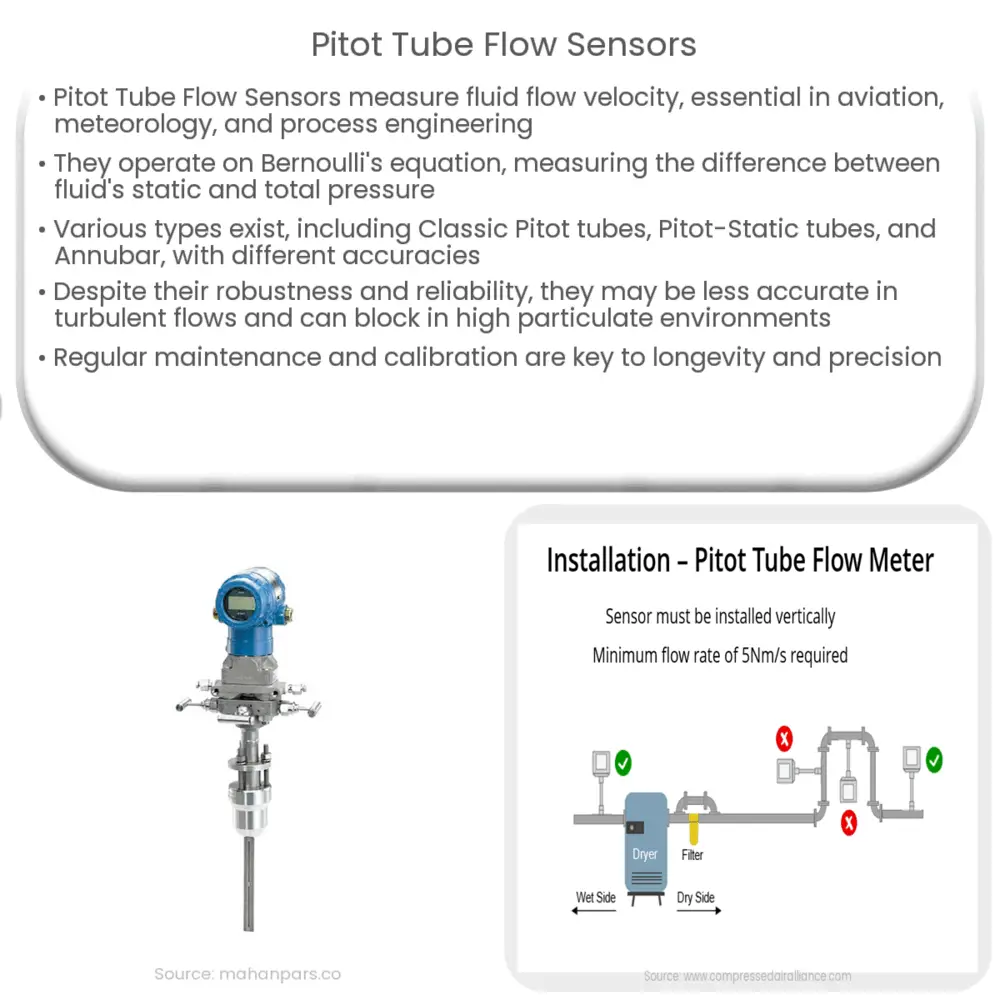

Pitot Tube Flow Sensors, also known as Pitot tubes, are simple, yet efficient devices that play a significant role in various fields, including aviation, meteorology, and process engineering. These instruments measure fluid flow velocity, providing valuable insights in both scientific and industrial applications.

The Principle of Operation

Named after its inventor, Henri Pitot, a French engineer in the 18th century, the Pitot tube operates on a simple, yet effective principle. This principle is closely tied to Bernoulli’s equation that relates the pressure, velocity, and potential energy of a fluid.

The Pitot tube comprises two tubes: a central tube pointing directly into the fluid flow and an annular ring around it, open at its sides. The fluid’s static pressure is measured through the annular ring, while the central tube measures the fluid’s total pressure (static plus dynamic). The fluid flow velocity is then determined by calculating the difference between these two pressures, known as the dynamic pressure.

Types of Pitot Tube Flow Sensors

- Classic Pitot tube: The traditional form of this device, it consists of an open-ended tube pointing directly into the fluid flow. It’s simple and cost-effective but is susceptible to errors due to its design.

- Pitot-Static tube: This variant, also known as a Prandtl tube, incorporates an additional ring of holes around the primary tube. This design allows for the simultaneous measurement of static and total pressures, increasing accuracy.

- Annubar: Also known as an averaging Pitot tube, the Annubar is a multi-port self-averaging Pitot tube that measures the flow rate with increased accuracy across a range of flow conditions. It’s widely used in industrial applications due to its precision and versatility.

Applications of Pitot Tube Flow Sensors

The widespread use of Pitot tubes reflects their versatility and accuracy. Their primary application lies in the aviation industry, where they’re integral components in an aircraft’s airspeed indicator. Furthermore, in meteorology, they’re used to gauge wind speed, while in process engineering, they are used to measure fluid flow in pipelines.

Regardless of the application, understanding the principle of operation, types, and uses of Pitot Tube Flow Sensors provides insight into their invaluable contribution to various fields.

Advantages and Limitations

Pitot Tube Flow Sensors present several advantages that make them popular in various fields. They are robust, reliable, and don’t require any moving parts, which makes them highly durable. In addition, they provide accurate, direct measurements of fluid velocity, which can be crucial in many engineering and scientific applications.

However, they are not without their limitations. Pitot tubes can be less accurate in turbulent or multi-directional flows due to their design. They also rely on the assumption that the fluid is incompressible, which may not always hold true, particularly for gases under high pressure. Another challenge is that they are susceptible to blockage, especially in environments with a high particulate load, which can affect the sensor’s performance.

Considerations when Selecting a Pitot Tube

Several factors should be considered when selecting a Pitot tube for an application. First, consider the nature of the fluid and the flow conditions, including the flow speed and whether the flow is laminar or turbulent. The accuracy requirement of the application and environmental conditions, such as temperature and pressure, also play a crucial role. Lastly, the material of the Pitot tube should be compatible with the fluid to prevent corrosion or other adverse interactions.

Maintenance and Calibration

To ensure the longevity and accuracy of a Pitot tube, regular maintenance and calibration are essential. Cleaning the tube to prevent blockage and routinely calibrating it to counteract any drift in readings are recommended best practices. For calibration, it is advisable to follow the manufacturer’s guidelines or seek the assistance of a professional calibration service.

Conclusion

In conclusion, Pitot Tube Flow Sensors are indispensable instruments in many scientific and industrial applications. Their robustness, accuracy, and versatility make them a preferred choice for fluid flow measurement. However, understanding their operation, strengths, and limitations is key to leveraging their capabilities effectively. As technology continues to advance, we may see improvements and innovations that further enhance the performance and application range of these remarkable devices.