A brushless DC magnetic actuator is an efficient, low-maintenance electromechanical device that converts electrical energy into precise mechanical motion.

Brushless DC Magnetic Actuator: An Introduction

As the demand for efficient and precise motion control systems continues to grow, the importance of actuators in various industries has become more apparent. Among the numerous types of actuators available in the market, Brushless DC (BLDC) magnetic actuators stand out due to their remarkable performance and numerous advantages. In this article, we will delve into the world of BLDC magnetic actuators, exploring their working principle, benefits, and applications.

Understanding the Basics: Working Principle of BLDC Magnetic Actuators

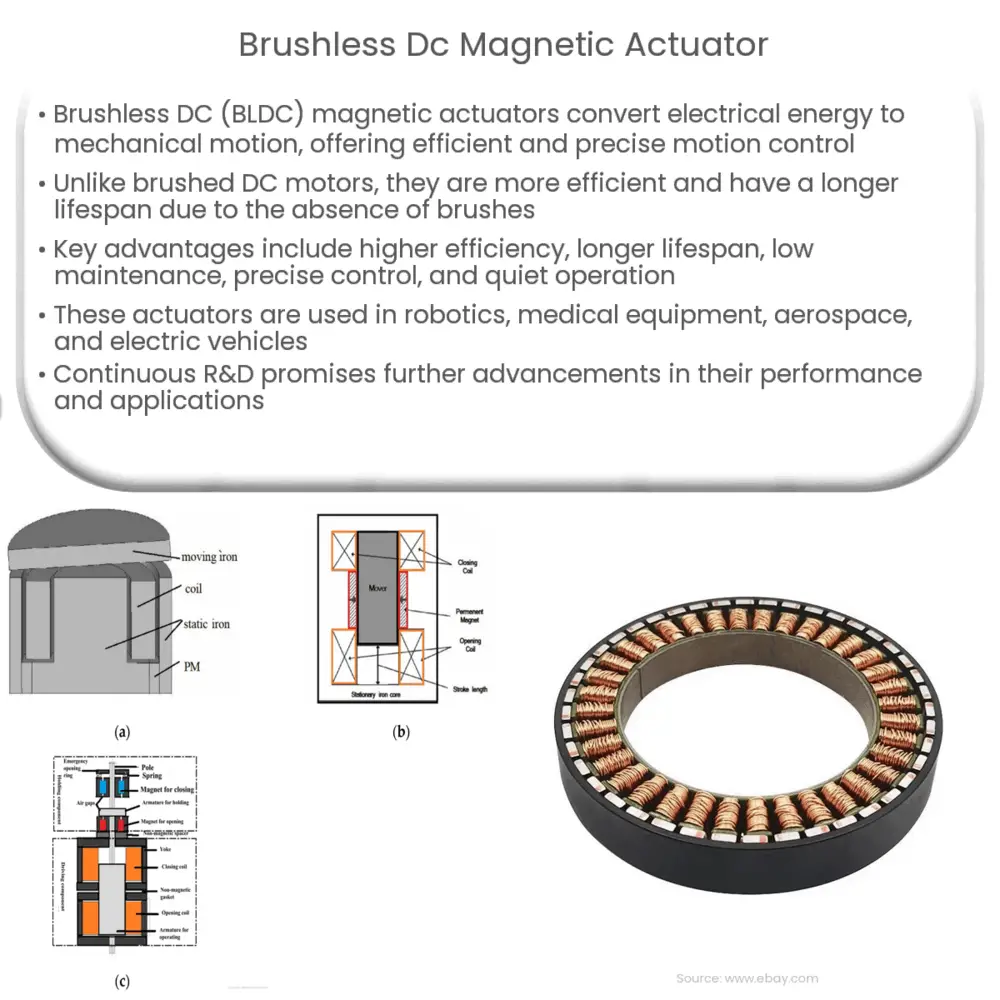

BLDC magnetic actuators, also known as brushless direct current magnetic actuators, are electromechanical devices that convert electrical energy into mechanical motion. These actuators consist of a stator, a rotor, and a control system. The stator contains stationary electromagnets, while the rotor has permanent magnets mounted on it. The control system is responsible for managing the current flow through the stator’s electromagnets, which in turn generates a magnetic field that interacts with the permanent magnets on the rotor, causing it to rotate.

Unlike brushed DC motors, which rely on mechanical brushes for commutation, BLDC magnetic actuators use an electronic controller to regulate the current flow. This eliminates the need for brushes, resulting in a more efficient, reliable, and low-maintenance system. Furthermore, the absence of brushes reduces friction and wear, prolonging the actuator’s lifespan and ensuring smooth operation.

Advantages of Brushless DC Magnetic Actuators

BLDC magnetic actuators offer numerous advantages over their brushed counterparts and other types of actuators. Some of the key benefits include:

- Higher Efficiency: The elimination of mechanical brushes reduces energy loss due to friction, leading to a more efficient system with lower power consumption.

- Longer Lifespan: The absence of brushes and commutators minimizes wear and tear, resulting in an extended operational life for the actuator.

- Lower Maintenance: With no brushes to replace and fewer moving parts, BLDC magnetic actuators require minimal maintenance, reducing downtime and overall costs.

- Precise Control: The electronic control system allows for accurate and smooth motion control, making BLDC magnetic actuators ideal for applications that require high precision and responsiveness.

- Low Noise Operation: Due to the absence of brushes and reduced mechanical friction, BLDC magnetic actuators operate more quietly than their brushed counterparts.

Applications of Brushless DC Magnetic Actuators

BLDC magnetic actuators have found widespread use in various industries, thanks to their versatility and superior performance. Some of the most common applications include:

- Robotics and automation systems, where precise motion control is crucial.

- Medical equipment, such as surgical instruments and prosthetic devices, which require high precision and reliability.

- Aerospace and defense systems, where durability and low maintenance are essential.

- Electric vehicles and renewable energy systems, which benefit from the high efficiency and low noise operation of BLDC magnetic actuators.

Selecting the Right BLDC Magnetic Actuator

When choosing a BLDC magnetic actuator for a specific application, several factors must be taken into consideration. These factors include:

- Load Requirements: The actuator should be capable of handling the load and torque requirements of the application. Ensure that the actuator’s specifications match the demands of your system.

- Speed and Acceleration: Evaluate the required speed and acceleration for your application and choose an actuator that can deliver the necessary performance.

- Positioning Accuracy: For applications that demand high precision, select an actuator with a high-resolution feedback system, such as an encoder or a resolver.

- Operating Environment: Consider the operating conditions, such as temperature, humidity, and potential exposure to dust or chemicals, and choose an actuator that is designed to withstand these challenges.

- Size and Weight Constraints: The physical dimensions and weight of the actuator should be compatible with your system’s design constraints.

By evaluating these factors, you can select a BLDC magnetic actuator that meets the specific requirements of your application and ensures optimal performance.

Future Developments in BLDC Magnetic Actuators

As the demand for advanced motion control systems continues to increase, researchers and manufacturers are constantly working to improve the performance and efficiency of BLDC magnetic actuators. Some of the promising developments in this field include:

- Advanced Materials: The use of novel materials, such as high-energy permanent magnets and low-loss electrical steel, can further enhance the efficiency and power density of BLDC magnetic actuators.

- Integrated Electronics: The integration of control electronics into the actuator design can reduce the size and weight of the overall system while improving reliability and performance.

- Smart Actuators: The incorporation of sensors, artificial intelligence, and advanced control algorithms can enable BLDC magnetic actuators to adapt to changing conditions, optimize performance, and increase operational flexibility.

Conclusion

Brushless DC magnetic actuators have become an increasingly popular choice for a wide range of applications, thanks to their superior performance, efficiency, and reliability. By understanding their working principle, benefits, and selection criteria, engineers and system designers can make informed decisions when incorporating these advanced actuators into their projects. As research and development continue to advance in this field, we can expect further improvements in the performance and capabilities of BLDC magnetic actuators, paving the way for even more innovative and sophisticated motion control solutions.