Linear magnetic actuators deliver precise, efficient, and reliable motion control, revolutionizing industries such as automation, medical devices, and transportation.

Linear Magnetic Actuators: Revolutionizing Motion Control

Introduction

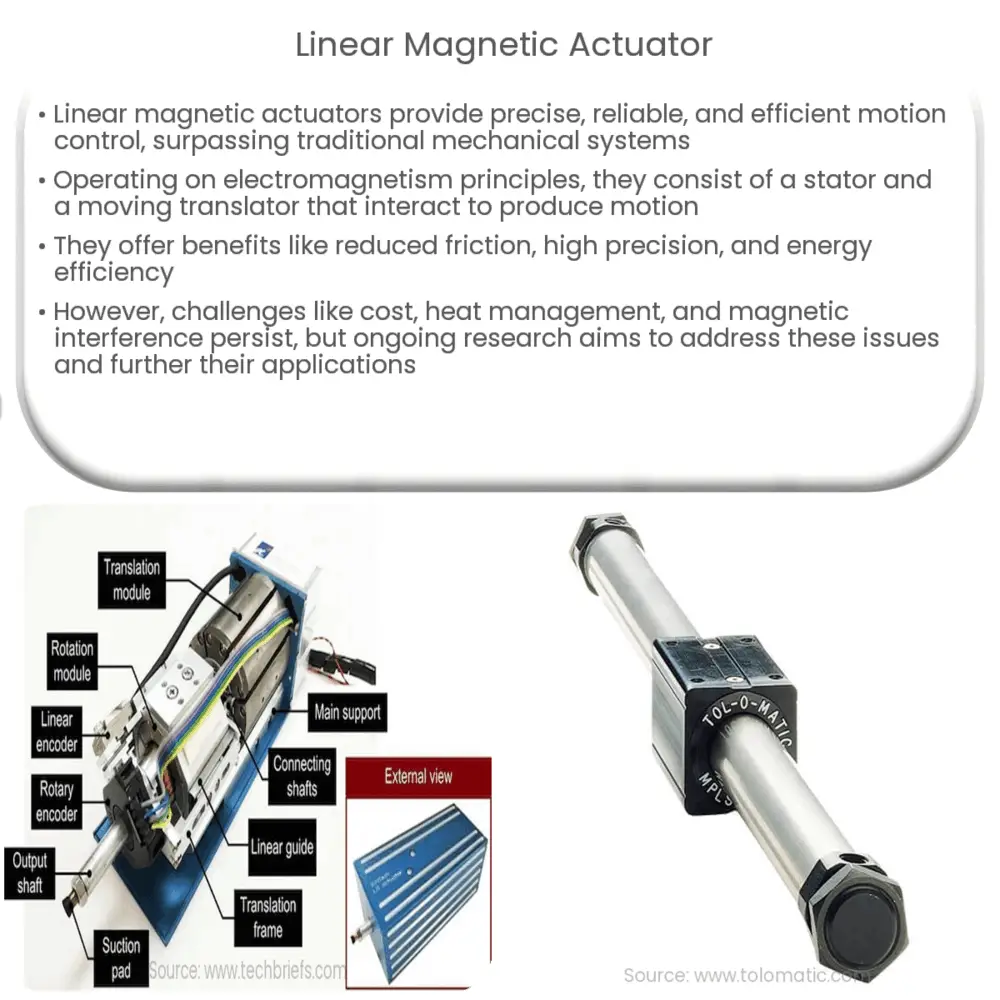

Linear magnetic actuators are innovative devices that provide precise, reliable, and efficient motion control solutions for various applications. This technology offers numerous advantages over traditional mechanical systems, including reduced friction, wear, and maintenance, as well as increased efficiency and accuracy. In this article, we will discuss the fundamental principles of linear magnetic actuators, their design, and how they are transforming the world of motion control.

Principles of Linear Magnetic Actuators

Linear magnetic actuators operate on the basic principles of electromagnetism, which involve the interaction between electric currents and magnetic fields to produce motion. A linear magnetic actuator typically consists of a stationary stator and a moving translator (plunger), both containing magnetic components. The stator, which houses coils of wire, creates a magnetic field when an electric current is passed through it. This magnetic field interacts with the magnets in the translator, generating a linear force that propels the translator along the stator’s axis.

There are two main types of linear magnetic actuators: permanent magnet and variable reluctance. Permanent magnet actuators utilize permanent magnets in the translator, while variable reluctance actuators use ferromagnetic materials that become temporarily magnetized when exposed to a magnetic field. Both types have their advantages and applications, with permanent magnet actuators offering higher force density and variable reluctance actuators providing greater flexibility in design.

Design Considerations

When designing a linear magnetic actuator, engineers must consider several factors to ensure optimal performance and efficiency. These factors include:

- Magnetic materials: The choice of magnetic materials for the stator and translator significantly affects the actuator’s performance. High-performance materials such as neodymium iron boron (NdFeB) magnets and high-grade electrical steel can significantly enhance force output and efficiency.

- Coil design: The configuration and size of the coils in the stator determine the actuator’s force output and efficiency. Optimizing coil design can lead to improved performance and reduced power consumption.

- Thermal management: Managing heat generated by the actuator is crucial to ensure consistent performance and prevent overheating. Adequate cooling mechanisms, such as air or liquid cooling systems, can help maintain optimal operating temperatures.

- Bearing systems: To minimize friction and wear, linear magnetic actuators often incorporate non-contact bearing systems, such as air bearings or magnetic levitation. These systems allow for smooth, accurate motion with minimal maintenance requirements.

Applications and Benefits

Linear magnetic actuators are finding their way into a wide range of industries and applications due to their numerous benefits. Some common applications include:

- Automation: In automated manufacturing systems, linear magnetic actuators provide precise positioning and high-speed motion control for assembly, packaging, and material handling processes.

- Medical devices: Linear magnetic actuators are used in medical equipment such as surgical robots, drug delivery systems, and diagnostic imaging equipment, where accuracy, reliability, and cleanliness are critical.

- Transportation: Magnetic levitation trains utilize linear magnetic actuators for propulsion and guidance, offering faster and more efficient transportation alternatives.

Linear magnetic actuators offer several advantages over traditional mechanical systems, including:

- Reduced friction and

wear: Due to their non-contact nature, linear magnetic actuators experience minimal friction and wear, resulting in extended lifespan and reduced maintenance requirements. - High precision and accuracy: Linear magnetic actuators provide excellent position control and repeatability, making them ideal for applications requiring precise motion control.

- Efficiency: With optimized design and reduced energy loss due to friction, linear magnetic actuators can be more energy-efficient than traditional mechanical systems.

- Compact size and scalability: Linear magnetic actuators can be designed in various sizes, making them suitable for a wide range of applications, from miniature devices to large-scale industrial machinery.

Challenges and Future Developments

While linear magnetic actuators offer numerous advantages, they also face some challenges that need to be addressed to further improve their performance and broaden their applications:

- Cost: The high cost of magnetic materials and complex manufacturing processes can make linear magnetic actuators more expensive than traditional mechanical systems. However, advances in material science and manufacturing technologies may help reduce costs in the future.

- Heat generation: Managing heat generation in linear magnetic actuators is crucial to prevent performance degradation and ensure reliability. Further research and development in thermal management solutions will be essential to overcome this challenge.

- Magnetic shielding: Linear magnetic actuators can generate stray magnetic fields that may interfere with nearby electronic devices or other sensitive components. Developing effective magnetic shielding solutions is essential to mitigate these effects.

Despite these challenges, linear magnetic actuators continue to revolutionize the motion control industry, with ongoing research and development efforts aimed at enhancing their performance, efficiency, and scalability. As technology advances, we can expect linear magnetic actuators to play an increasingly significant role in various industries, from manufacturing and transportation to medical devices and beyond.

Conclusion

Linear magnetic actuators offer a transformative solution for motion control applications, providing precision, efficiency, and reliability that outperforms traditional mechanical systems. As advancements in material science, engineering, and manufacturing continue to evolve, linear magnetic actuators are poised to become an increasingly vital component in a wide range of industries, driving innovation and improving the functionality of numerous applications. By understanding the principles, design considerations, and benefits of linear magnetic actuators, we can better appreciate their potential to shape the future of motion control technology.