E-core actuators are efficient electromechanical devices, converting electrical energy into precise mechanical motion using an E-shaped iron core.

E-core Actuator: A Revolution in Electromechanical Motion

The E-core actuator has taken the world of electromechanical motion by storm. With its unique design and unparalleled efficiency, this innovative actuator has proven itself to be a game-changer in various industries, such as robotics, automotive, and aerospace. In this article, we will delve into the principles behind the E-core actuator, its benefits over traditional actuators, and the potential applications it holds for the future.

What is an E-core Actuator?

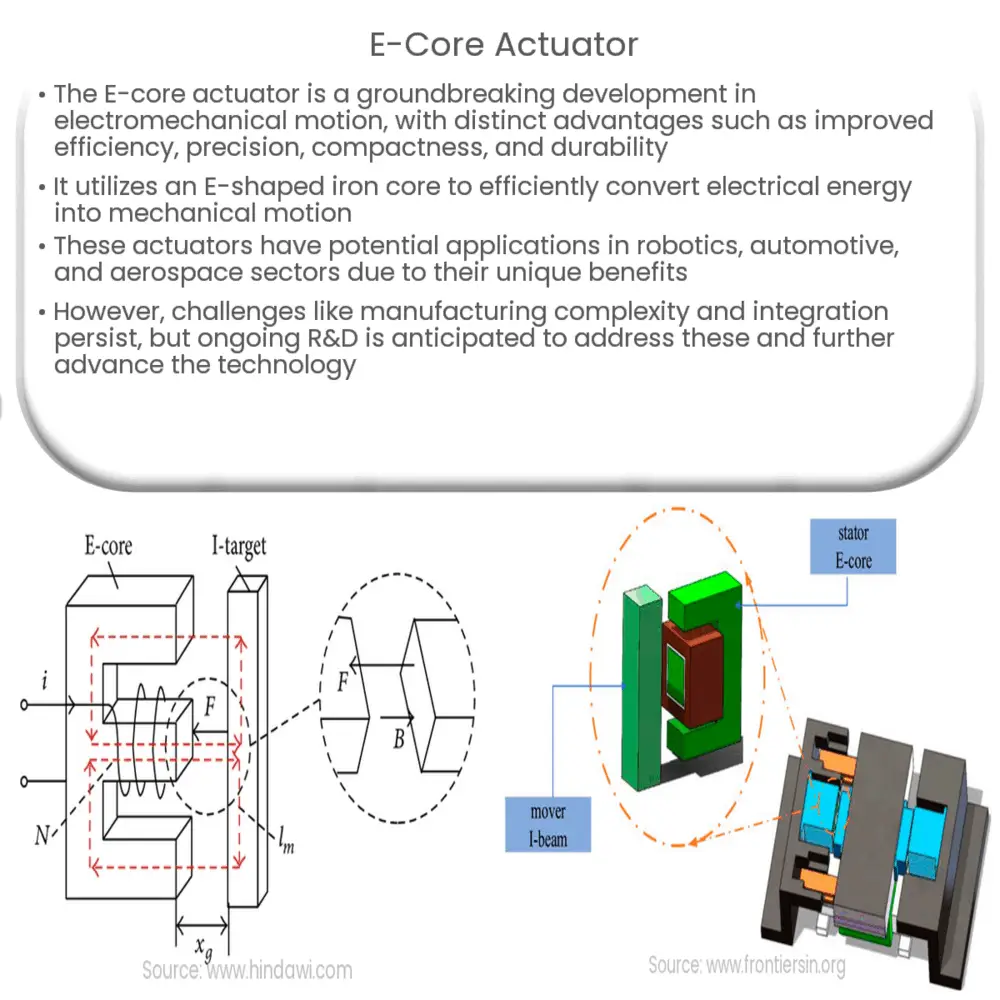

An E-core actuator is an electromechanical device designed to convert electrical energy into mechanical motion. It achieves this through the use of an E-shaped iron core, which is placed between two coils of wire. When current passes through the coils, a magnetic field is generated, and the resulting force causes the E-core to move. This motion can be linear or rotational, depending on the design of the actuator.

Benefits of E-core Actuators

The E-core actuator boasts several advantages over conventional actuators, making it an ideal choice for a wide range of applications. Some of the most notable benefits include:

1. Improved Efficiency

E-core actuators are designed to minimize energy losses that typically occur in traditional actuators. This is achieved by reducing the magnetic reluctance in the iron core, which allows for a more efficient transfer of energy from the electrical source to the mechanical load. As a result, E-core actuators offer greater efficiency compared to their counterparts, which translates into reduced power consumption and lower operational costs.

2. Increased Precision

Thanks to their unique design, E-core actuators are capable of providing highly precise motion control. The E-shaped core enables smooth and accurate linear or rotational movements, making them well-suited for applications that demand exact positioning and control.

3. Compact and Lightweight

E-core actuators are significantly more compact and lightweight compared to other actuator types. This is due to the reduced number of components required in their construction, which ultimately results in a smaller and more streamlined design. The compact size and reduced weight make E-core actuators ideal for applications where space and weight constraints are a concern, such as in robotics and aerospace.

4. Enhanced Durability

The E-core actuator’s robust construction and minimal moving parts contribute to its enhanced durability. This ensures a longer operational life and reduced maintenance requirements, making it a cost-effective solution for various applications.

Potential Applications of E-core Actuators

With their numerous advantages, E-core actuators have the potential to revolutionize various industries. Some of the most promising applications include:

- Robotics: The precision, efficiency, and compact size of E-core actuators make them an ideal choice for robotic applications, from industrial robots to medical devices and exoskeletons.

- Automotive: E-core actuators can be used in electric and hybrid vehicles to provide precise control for steering, suspension, and braking systems, improving both performance and safety.

- Aerospace: The lightweight and compact nature of E-core actuators allows them to be easily integrated into aircraft and spacecraft systems, offering improved efficiency and reduced weight.

Challenges and Future Developments

While E-core actuators offer several advantages over traditional actuators, they are not without their challenges. Some of the key issues that need to be addressed include:

- Manufacturing complexity: The unique design of E-core actuators requires advanced manufacturing techniques and specialized materials, which may result in higher production costs compared to conventional actuators.

- Integration with existing systems: Retrofitting E-core actuators into existing systems can be challenging, as they may require significant modifications to accommodate the new technology.

- Standardization: As E-core actuators are a relatively new technology, industry-wide standards are still being developed, which may slow down widespread adoption.

Despite these challenges, ongoing research and development efforts are paving the way for improvements in E-core actuator technology. Future developments are expected to focus on:

- Material advancements: The use of advanced materials, such as high-performance magnetic alloys, can further improve the efficiency and performance of E-core actuators.

- Miniaturization: Continued efforts in miniaturization will allow E-core actuators to be integrated into even smaller devices and systems, further expanding their range of applications.

- Advanced control algorithms: The development of sophisticated control algorithms can enhance the precision and responsiveness of E-core actuators, making them even more suitable for high-performance applications.

Conclusion

The E-core actuator represents a major breakthrough in the field of electromechanical motion, offering numerous benefits over traditional actuators, including improved efficiency, precision, compactness, and durability. As a result, E-core actuators have the potential to revolutionize various industries, such as robotics, automotive, and aerospace.

While challenges remain in terms of manufacturing complexity, integration with existing systems, and standardization, ongoing research and development efforts are expected to overcome these hurdles and drive further advancements in E-core actuator technology. As material advancements, miniaturization, and advanced control algorithms continue to progress, the future of E-core actuators appears bright, with the promise of even greater performance and application potential.