S-type load cells are versatile, high-accuracy sensors for measuring tensile and compressive forces in various industries and applications.

S-Type Load Cell: An Overview of its Applications and Benefits

Introduction

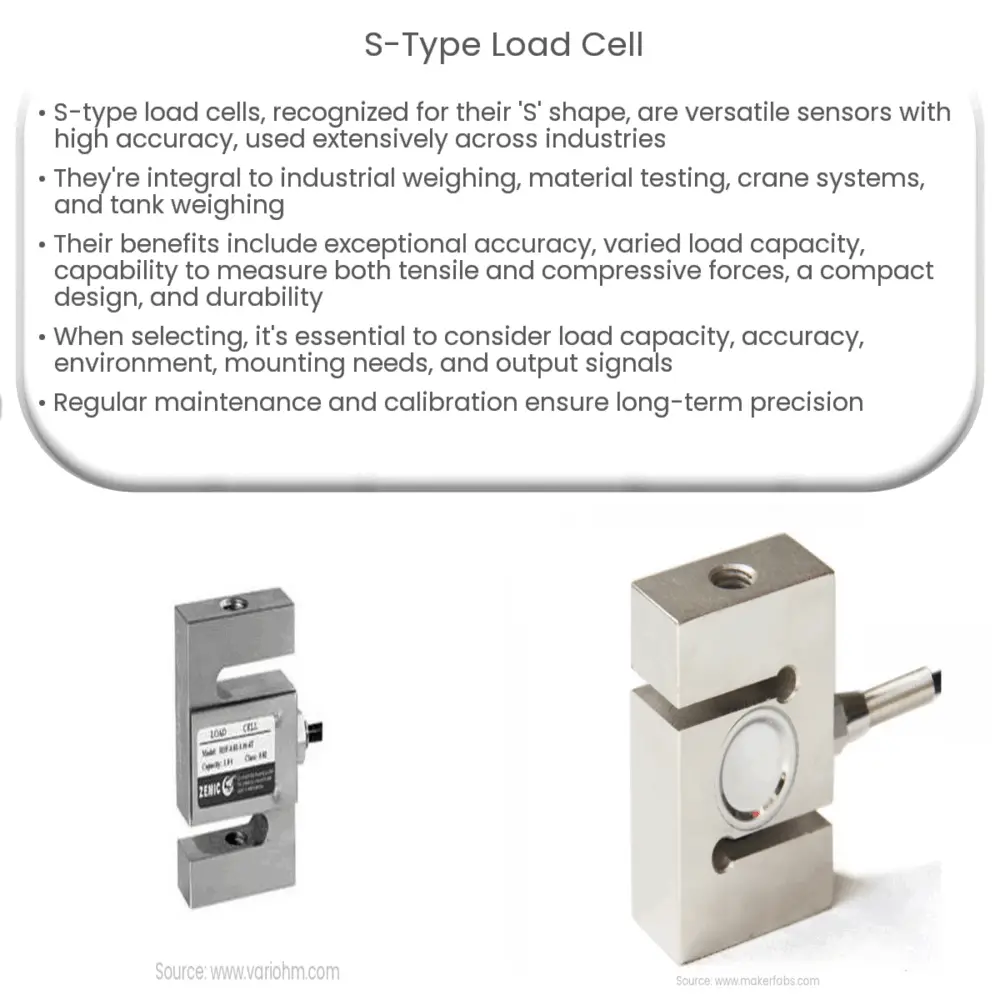

S-type load cells, also known as S-beam load cells, are versatile and widely used sensors in various industries due to their unique design and high accuracy. They derive their name from their distinctive ‘S’ shape, which allows them to measure tensile and compressive forces effectively. In this article, we will explore the applications, advantages, and key considerations when choosing an S-type load cell for your specific needs.

Applications

S-type load cells are employed in a diverse range of applications due to their versatility and adaptability. Some common use cases include:

- Industrial weighing systems: S-type load cells are commonly used in industrial scales and batch weighing systems, as they can accurately measure weight within a specified range.

- Material testing: They are extensively used in material testing machines for determining the tensile and compressive strength of materials, such as metals, plastics, and composites.

- Crane and hoist systems: S-type load cells are widely used in overhead crane systems to ensure safe and efficient operation by measuring the load on the hook.

- Tank and silo weighing: These load cells can be used to measure the weight of tanks and silos in industries like agriculture, food processing, and chemicals.

Advantages

S-type load cells offer several benefits, which contribute to their widespread adoption in various industries. Some of the key advantages include:

- High accuracy: S-type load cells provide highly accurate measurements, with minimal interference from external factors such as temperature changes and side loads.

- Load capacity: They are available in a wide range of capacities, allowing them to measure a broad spectrum of forces, from a few kilograms to several tons.

- Versatility: As previously mentioned, S-type load cells can measure both tensile and compressive forces, making them suitable for a wide range of applications.

- Compact design: Their compact size and low profile make them easy to integrate into existing systems and machinery.

- Durability: S-type load cells are typically made from stainless steel or alloy steel, ensuring long-lasting performance in harsh environments and under heavy loads.

Key Considerations when Choosing an S-Type Load Cell

Selecting the appropriate S-type load cell for your specific needs involves several factors. Here are some key considerations to keep in mind:

- Load capacity: Determine the maximum force that the load cell will need to measure and choose one with a suitable capacity. Overloading a load cell can result in inaccurate measurements or even permanent damage to the device.

- Accuracy: Choose a load cell with an accuracy level that meets your application requirements. Higher accuracy load cells may come at a higher cost, so it is essential to balance accuracy with budgetary constraints.

- Environment: Consider the operating environment in which the load cell will be used, such as temperature, humidity, and exposure to chemicals. Select a load cell with appropriate materials and ingress protection (IP) ratings to ensure long-lasting performance in challenging conditions.

- Mounting and installation: Make sure the load cell is compatible with your system’s mounting and installation requirements. Some S-type load cells come with built-in mounting hardware, while others may require additional components.

- Output signal: Load cells can provide output signals in various formats, such as analog voltage, current, or digital signals. Choose a load cell with an output signal that is compatible with your data acquisition system or display.

Maintenance and Calibration

To ensure the continued accuracy and reliability of your S-type load cell, regular maintenance and calibration are essential. Here are some tips to help you maintain your load cell:

- Visual inspection: Periodically inspect the load cell for signs of physical damage, corrosion, or wear. Address any issues promptly to prevent further deterioration.

- Cleaning: Clean the load cell as needed, using a mild detergent and a soft cloth. Avoid using abrasive materials or harsh chemicals, as they may damage the load cell’s surface.

- Calibration: Regularly calibrate your load cell to ensure accurate measurements. The frequency of calibration will depend on the specific application and environment, but a general recommendation is to calibrate at least once a year or whenever the load cell is reinstalled after maintenance.

- Record keeping: Maintain a record of calibration results, maintenance activities, and any issues encountered. This documentation can help identify trends and potential problems, allowing you to address them proactively.

Conclusion

S-type load cells are versatile, accurate, and durable sensors that are widely used in various industries for measuring tensile and compressive forces. By carefully considering factors such as load capacity, accuracy, environment, mounting, and output signal, you can select the right S-type load cell for your specific needs. Regular maintenance and calibration will ensure that your load cell continues to deliver reliable and accurate measurements throughout its service life.