Explore the comprehensive guide on pneumatic motors: their working principle, types, benefits, limitations, and various applications.

Pneumatic Motors: A Comprehensive Understanding

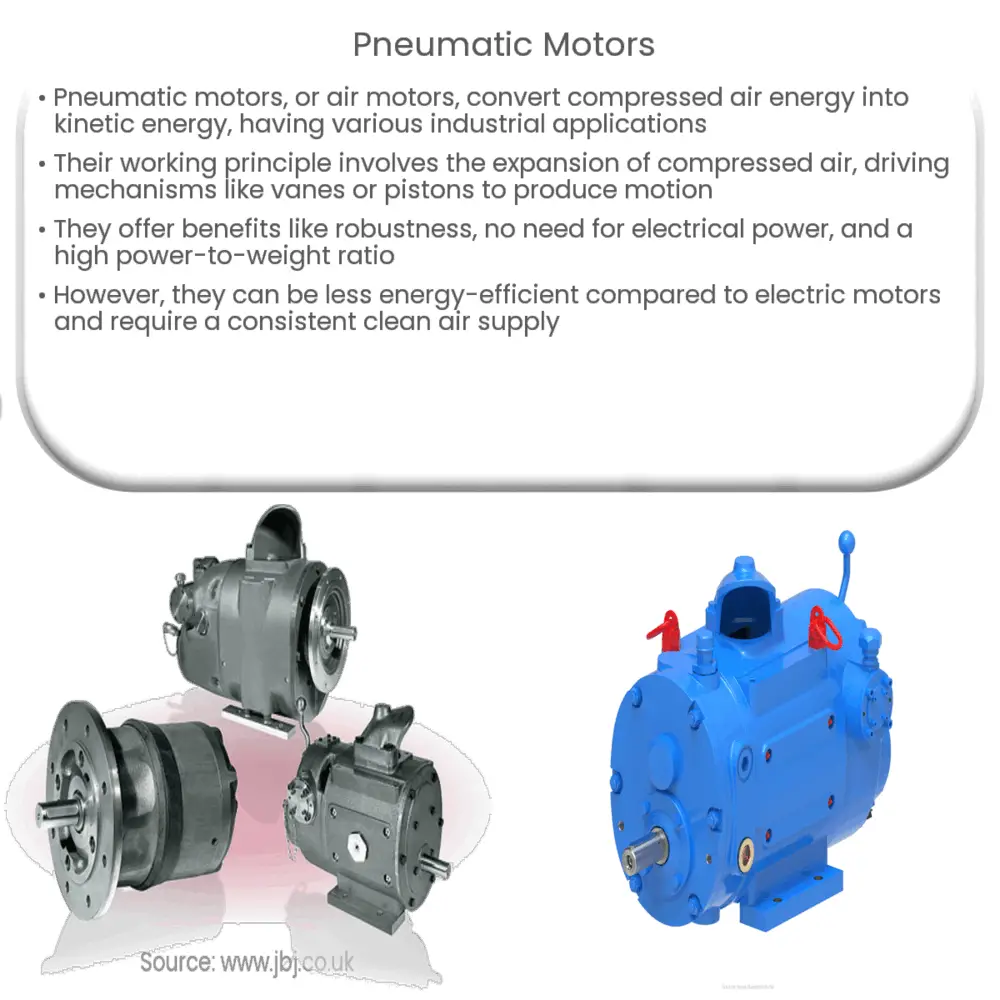

Pneumatic motors, also referred to as air motors, are mechanical devices that transform the energy held within compressed air into kinetic energy or mechanical work. These devices offer a plethora of benefits and have diverse applications across multiple industries.

Working Principle of Pneumatic Motors

The fundamental working principle of a pneumatic motor is the conversion of potential energy into kinetic energy. This conversion happens when the stored compressed air expands within the motor. Unlike conventional motors, the energy transformation in pneumatic motors involves the expansive properties of gases.

The compressed air, supplied from a remote source, is guided into a cylinder where it forces a piston to move. This process, repeated rapidly, generates continuous rotational motion in the connected output shaft.

Types of Pneumatic Motors

- Vane motors: Vane motors operate by the expansion of compressed air against vanes attached to a rotor, causing the rotor to spin. They are primarily used in handheld power tools due to their lightweight design and compact size.

- Piston motors: Piston motors are preferred for applications that require high torque. They comprise one or more reciprocating pistons, which, when expanded by compressed air, push the crankshaft to generate motion.

- Rotary vane motors: Rotary vane motors are essentially a type of vane motor, but with a more complex mechanism. They possess two or more vanes that extend from the rotor, sliding in and out to maintain contact with the housing, thereby ensuring efficient energy transfer.

Benefits of Pneumatic Motors

Pneumatic motors offer distinct advantages, making them a popular choice across a wide range of applications. They are well-regarded for their robustness, as they can withstand harsh environments without significant wear and tear. They also stand out for their ability to function without the need for any electrical power, making them a safer choice in hazardous environments where sparking could lead to explosions or fires.

Moreover, pneumatic motors are known for their high power-to-weight ratio, a trait that lends them perfectly to handheld power tools and other portable devices. Their power delivery is easily adjustable, giving users granular control over their speed and torque.

Despite these remarkable benefits, pneumatic motors are not without their limitations. Understanding these helps in making informed decisions based on the specific requirements of a given application. But that’s a topic for another discussion.

Limitations of Pneumatic Motors

While pneumatic motors offer numerous advantages, they also present certain limitations. First, they require an extensive supply of compressed air, which can necessitate bulky infrastructure, especially for larger applications. This air supply also needs to be clean and dry to prevent internal corrosion and wear, adding to maintenance requirements.

Another limitation is the relative inefficiency of pneumatic motors compared to electric motors. Despite having a high power-to-weight ratio, the overall energy efficiency of pneumatic systems is usually lower due to energy losses in the compression and distribution of air.

Lastly, despite the control over speed and torque, pneumatic motors generally lack the precise control offered by electric motors. This may limit their use in applications where very precise movements are needed.

Applications of Pneumatic Motors

Despite the limitations, the unique characteristics of pneumatic motors make them suitable for many applications. Their intrinsic safety and ruggedness make them ideal for use in potentially explosive environments such as oil and gas industries, mining, and construction.

- In handheld power tools, the high power-to-weight ratio of vane motors is leveraged to offer robust performance in a compact form.

- In the food industry, pneumatic motors are preferred for their ability to operate safely and cleanly without the risk of contamination.

- In automotive applications, they are used in tire changing machines, where they offer high torque output and resilience against rough usage.

Conclusion

Pneumatic motors, with their unique blend of attributes and capabilities, hold a distinctive position in the realm of mechanical devices. Though not without their limitations, their durability, adaptability, and inherent safety make them an essential tool in a multitude of industries.

From powering handheld tools to driving machinery in hazardous environments, these motors are undeniably an integral part of the modern mechanical landscape. It’s clear that the future of pneumatic motors is bright, with continuous improvements and innovations likely to enhance their efficiency and expand their range of applications.