A pneumatic proximity sensor detects object presence without contact, using air pressure changes, ideal for harsh environments and various materials.

Pneumatic Proximity Sensor: An Overview

Introduction to Pneumatic Proximity Sensors

A pneumatic proximity sensor is an essential component in industrial automation systems, playing a pivotal role in detecting the presence or absence of an object without any physical contact. These sensors are widely used in manufacturing, robotics, and other applications where accurate and reliable object detection is necessary. In this article, we will explore the working principle, types, and key features of pneumatic proximity sensors, as well as their advantages and limitations.

Working Principle of Pneumatic Proximity Sensors

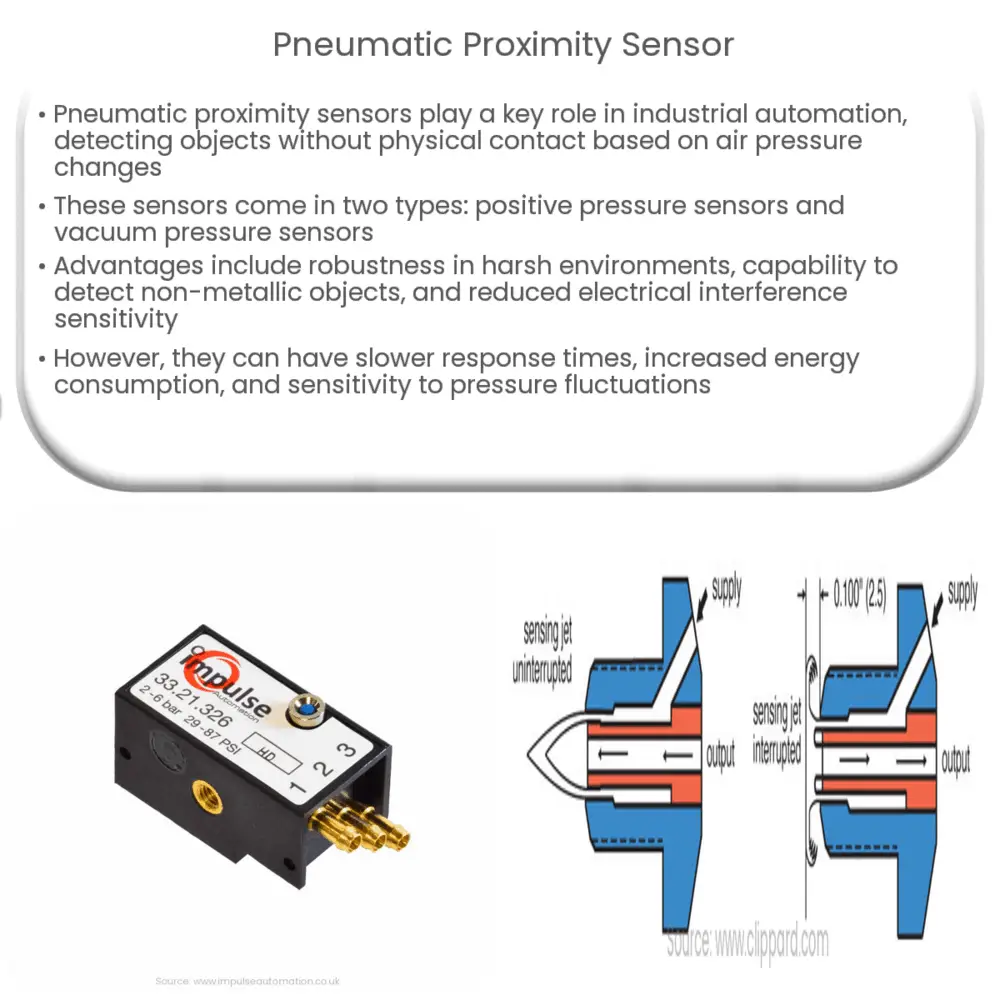

Pneumatic proximity sensors operate on the basis of changes in air pressure. When an object approaches the sensor, it causes a change in the air pressure within a specific sensing area. This change is then detected by the sensor, which sends an electrical signal to a control system to indicate the presence or absence of the object.

The main components of a pneumatic proximity sensor include a sensing nozzle, a diaphragm or piston, and a pressure switch. The sensing nozzle directs a stream of compressed air towards the target object, while the diaphragm or piston is responsible for converting the changes in air pressure into mechanical motion. The pressure switch, on the other hand, detects the motion of the diaphragm or piston and generates an electrical signal accordingly.

Types of Pneumatic Proximity Sensors

Pneumatic proximity sensors can be broadly classified into two types: positive pressure sensors and vacuum pressure sensors.

- Positive Pressure Sensors: These sensors use compressed air to detect the presence of an object. The air pressure within the sensing area increases when an object is near, causing the diaphragm or piston to move and triggering the pressure switch.

- Vacuum Pressure Sensors: Vacuum pressure sensors work on the principle of negative air pressure. They create a vacuum in the sensing area, and when an object approaches, the vacuum is disturbed, causing a change in pressure that activates the pressure switch.

Key Features and Applications

Pneumatic proximity sensors offer several advantages over their electronic counterparts, such as:

- Robustness and durability in harsh environments, including those with high temperature, dust, or moisture.

- Capability to detect non-metallic objects, as their sensing mechanism is not based on electromagnetic fields.

- Reduced sensitivity to electrical interference, making them suitable for use in electromagnetically noisy environments.

These features make pneumatic proximity sensors ideal for various applications, including assembly lines, packaging systems, robotics, and material handling systems.

Advantages of Pneumatic Proximity Sensors

In addition to the key features mentioned earlier, pneumatic proximity sensors offer several other advantages, such as:

- Low maintenance: These sensors have fewer moving parts and do not require complex electronics, resulting in lower maintenance requirements and longer service life.

- Simple installation and operation: Pneumatic proximity sensors can be easily integrated into existing systems without the need for extensive modifications, making them a cost-effective solution for object detection.

- High reliability: The non-contact sensing mechanism of pneumatic proximity sensors reduces the risk of false signals or sensor damage caused by collisions with target objects, ensuring reliable performance in various applications.

Limitations of Pneumatic Proximity Sensors

Despite their numerous advantages, pneumatic proximity sensors also have some limitations, including:

- Slower response times: Due to their reliance on air pressure changes, these sensors can have slower response times compared to electronic counterparts. This may be a concern in applications where rapid object detection is essential.

- Energy consumption: Pneumatic proximity sensors require a continuous supply of compressed air, which can lead to higher energy consumption and operating costs.

- Sensitivity to pressure fluctuations: Changes in ambient air pressure, such as those caused by temperature fluctuations or altitude changes, can affect the performance of these sensors, leading to potential inaccuracies in object detection.

Selection Criteria for Pneumatic Proximity Sensors

When choosing a pneumatic proximity sensor, it is essential to consider several factors, such as:

- Sensing range: The distance between the sensor and the target object that can be detected. This depends on the application requirements and the size of the objects being detected.

- Response time: The time taken by the sensor to detect an object and generate a signal. This is a crucial parameter for applications where rapid object detection is required.

- Environmental conditions: The operating temperature, humidity, and presence of dust or other contaminants should be considered when selecting a sensor to ensure optimal performance and durability.

- Compatibility: Ensure that the chosen sensor is compatible with the control system being used in the application, as well as the required mounting and connection options.

Conclusion

Pneumatic proximity sensors offer a robust and reliable solution for object detection in various industrial automation applications. Their non-contact sensing mechanism, durability, and reduced sensitivity to electrical interference make them suitable for harsh environments and a wide range of materials. However, it is essential to consider their limitations, such as slower response times and sensitivity to pressure fluctuations, when selecting the most suitable sensor for a specific application.