Hall Effect Proximity Sensors are non-contact devices that detect magnetic objects, offering high reliability and fast response times in various applications.

Hall Effect Proximity Sensor: An Introduction

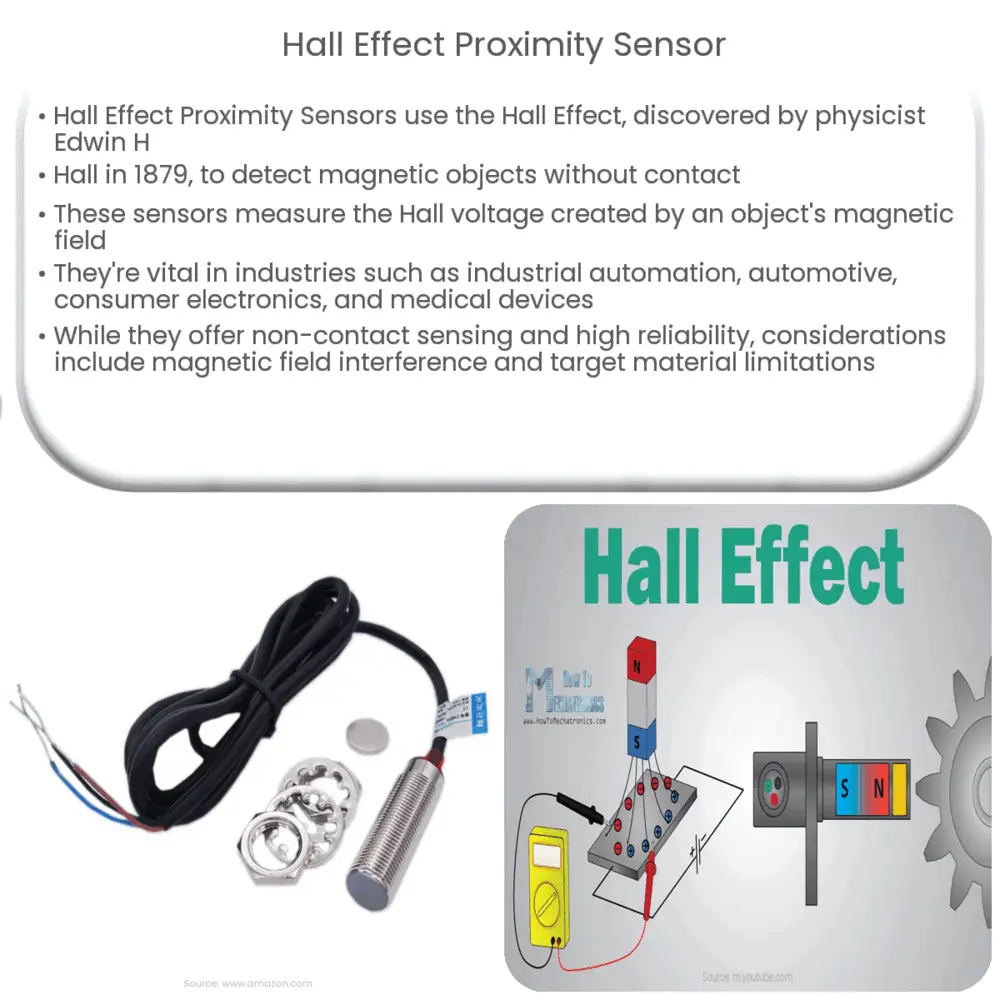

The Hall Effect is a fundamental phenomenon discovered in 1879 by American physicist Edwin H. Hall. This principle has found numerous applications in modern technology, one of which is the Hall Effect Proximity Sensor. In this article, we will explore the working principle, applications, and advantages of this sensor.

Understanding the Hall Effect

Before diving into the specifics of Hall Effect Proximity Sensors, it is crucial to understand the Hall Effect itself. The Hall Effect occurs when a magnetic field is applied perpendicular to the direction of the electric current in a conductor. As a result, the electrons in the conductor are deflected to one side, creating an electric field called the “Hall field. This field generates a voltage known as the “Hall voltage,” which is proportional to the strength of the magnetic field and the current flowing through the conductor.

Working Principle of Hall Effect Proximity Sensors

A Hall Effect Proximity Sensor is a type of non-contact sensor that detects the presence of a magnetic object by measuring the Hall voltage generated by the object’s magnetic field. The sensor is made up of three primary components: a Hall Effect sensor element, a signal processing circuit, and a switching element.

The Hall Effect sensor element is a semiconductor device that produces a Hall voltage when subjected to a magnetic field. The signal processing circuit amplifies and filters the Hall voltage to produce a usable output signal. The switching element, typically a transistor or a digital output, is then activated based on the output signal. When the magnetic object comes within the sensor’s detection range, the output signal changes, indicating the presence of the object.

Applications of Hall Effect Proximity Sensors

Hall Effect Proximity Sensors are employed in a wide variety of applications, including:

- Industrial Automation: These sensors are commonly used in automated systems for detecting the position of machine parts, counting objects on a production line, or measuring the speed of rotating equipment.

- Automotive Industry: Hall Effect sensors are essential components in various automotive systems, such as anti-lock braking systems (ABS), throttle position sensors, and crankshaft position sensors.

- Consumer Electronics: These sensors find use in devices like smartphones and tablets for features like screen rotation and magnetic cover detection.

- Medical Devices: Hall Effect Proximity Sensors play a role in medical equipment, including infusion pumps and prosthetic limb control systems.

In the next section, we will explore the advantages of using Hall Effect Proximity Sensors, as well as their limitations and some key considerations for their implementation.

Advantages of Hall Effect Proximity Sensors

Hall Effect Proximity Sensors offer several benefits, making them a popular choice for various applications:

- Non-contact Sensing: These sensors do not require physical contact with the target object, reducing wear and tear on the sensor and prolonging its operational life.

- High Reliability: Hall Effect sensors are immune to dust, dirt, and moisture, allowing for reliable operation in harsh environments.

- Fast Response Time: These sensors can detect changes in magnetic fields rapidly, providing quick and accurate measurements.

- Wide Operating Temperature Range: Hall Effect sensors typically have a broad operating temperature range, making them suitable for various applications and environments.

Limitations and Considerations

Despite their many advantages, Hall Effect Proximity Sensors also have some limitations and considerations to keep in mind:

- Magnetic Field Interference: Since these sensors rely on magnetic fields, they can be affected by external magnetic field sources, leading to false readings or reduced accuracy. Proper shielding and sensor placement can help mitigate this issue.

- Target Material: Hall Effect sensors can only detect objects with magnetic properties. Non-magnetic materials, such as plastic, wood, or aluminum, will not trigger the sensor.

- Temperature Effects: Although these sensors can operate over a wide temperature range, temperature variations can still impact the sensor’s performance. Compensation techniques may be required for applications with significant temperature fluctuations.

- Cost: Hall Effect Proximity Sensors can be more expensive than other types of proximity sensors, such as inductive or capacitive sensors, depending on the specific application and sensor complexity.

Conclusion

Hall Effect Proximity Sensors are versatile, non-contact sensing devices that leverage the Hall Effect to detect the presence of magnetic objects. With applications ranging from industrial automation to consumer electronics, these sensors offer numerous advantages such as high reliability and fast response time. However, it is essential to consider the sensor’s limitations, such as sensitivity to magnetic field interference and target material constraints, when selecting and implementing a Hall Effect Proximity Sensor in a particular application.