Multi-conductor cables efficiently transmit multiple electrical signals through a single cable, used in telecom, power, and A/V applications.

Understanding Multi-Conductor Cables

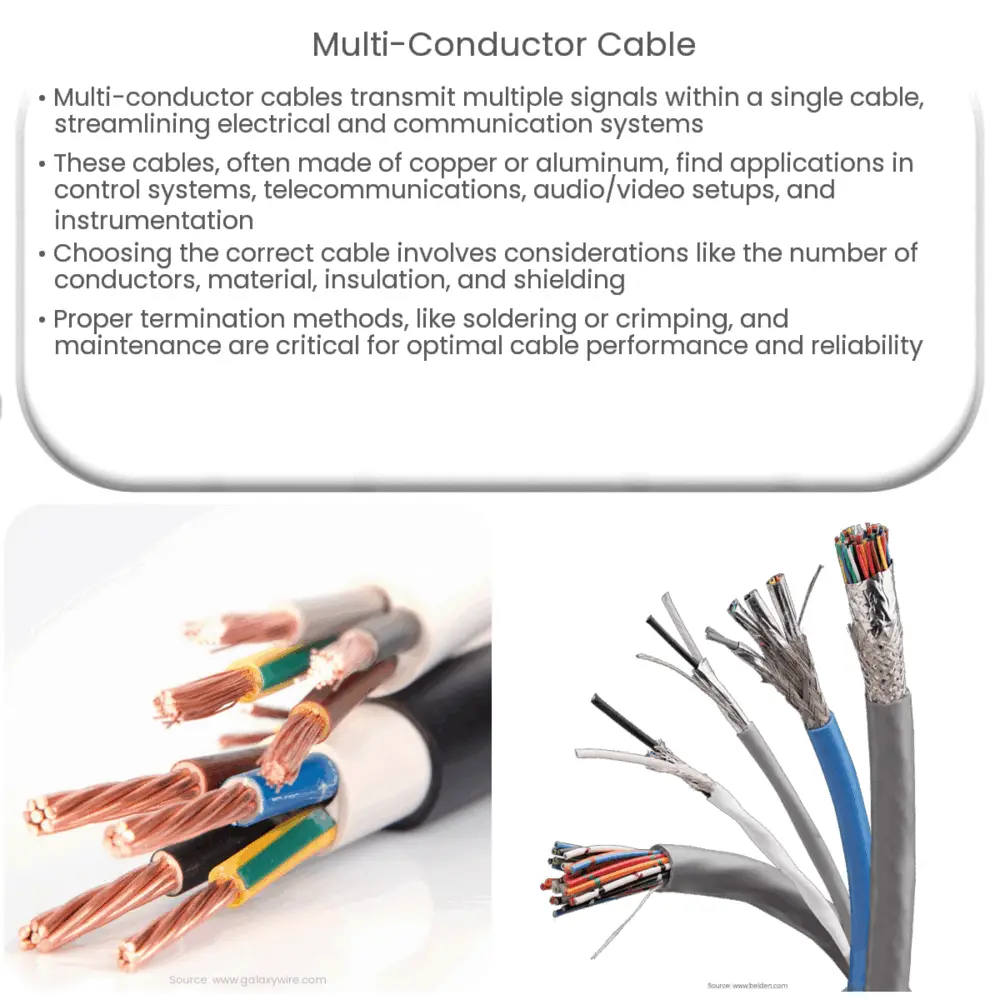

Multi-conductor cables are an essential component of modern electrical and communication systems. These cables are designed to transmit multiple signals through a single cable, simplifying cable management and reducing costs. In this article, we will explore the basics of multi-conductor cables, their applications, and how to choose the right cable for your project.

What is a Multi-Conductor Cable?

A multi-conductor cable consists of multiple insulated conductors, or wires, that are bundled together within a single cable jacket. Each conductor is made of a conductive material, typically copper or aluminum, and is surrounded by insulation to prevent electrical interference between the individual wires. Multi-conductor cables come in various configurations, with different numbers of conductors, conductor materials, and insulation types, depending on the intended application.

Applications of Multi-Conductor Cables

Multi-conductor cables are widely used across numerous industries, including telecommunications, power distribution, automotive, industrial automation, and consumer electronics. Some common applications include:

- Control Systems: Multi-conductor cables are often used in control systems to transmit control signals and power to devices, such as motors, solenoids, and sensors.

- Audio/Video: These cables are commonly used in audio and video applications for transmitting multiple audio or video signals simultaneously, such as in studio environments, broadcasting, or home theater systems.

- Telecommunications: In telecommunication systems, multi-conductor cables connect equipment, such as switches, routers, and servers, to transmit voice and data signals.

- Instrumentation: Multi-conductor cables are used to connect sensors, transducers, and other instrumentation devices to controllers and data acquisition systems in industrial and scientific settings.

Choosing the Right Multi-Conductor Cable

Selecting the appropriate multi-conductor cable for your project depends on various factors, including the required signal types, environmental conditions, and mechanical requirements. Here are some considerations to keep in mind:

- Number of Conductors: Determine the number of conductors needed to transmit the required signals. This can vary depending on the application and the specific devices being connected.

- Conductor Material: Choose a conductor material that offers suitable electrical performance, such as conductivity and resistance to corrosion. Copper is the most common choice, but aluminum may be used in certain applications for its lower cost and lighter weight.

- Insulation Material: Select an insulation material that provides adequate protection against electrical interference and meets any required temperature, flame resistance, and chemical resistance specifications.

- Shielding: If your application requires protection from electromagnetic interference (EMI), consider a multi-conductor cable with shielding. Shielding can be achieved through various methods, such as foil or braided shields, and is essential for maintaining signal integrity in environments with high levels of EMI.

In conclusion, multi-conductor cables are a versatile and cost-effective solution for transmitting multiple signals through a single cable. By understanding the basics of these cables and carefully considering your application requirements, you can select the right multi-conductor cable for your project.

Termination and Connector Options

Proper termination and connector selection are crucial for ensuring optimal performance and reliability of your multi-conductor cable assembly. There are several common termination methods and connector types available, such as soldering, crimping, and insulation displacement connectors (IDCs). When choosing a connector, consider factors like cable compatibility, ease of installation, and required durability.

- Soldering: Soldering is a widely used method for connecting conductors to connectors or terminals. This method provides a strong, reliable connection, but requires specialized tools and skills to perform correctly.

- Crimping: Crimping involves using a tool to mechanically compress a connector or terminal around the conductor, creating a secure connection. This method is quick, easy to perform, and can provide a reliable connection without the need for soldering.

- IDCs: Insulation displacement connectors pierce the insulation of the conductor and make contact with the conductive material inside. This method is fast and eliminates the need to strip insulation from the conductor, but may not be suitable for all cable types or applications.

Maintaining and Troubleshooting Multi-Conductor Cables

Proper maintenance and troubleshooting are essential for ensuring the long-term performance and reliability of your multi-conductor cable assemblies. Here are some tips for maintaining and troubleshooting your cables:

- Visual Inspection: Regularly inspect your cables for signs of damage, such as cuts, abrasions, or kinks. Damaged cables should be replaced to prevent potential signal loss or electrical hazards.

- Cable Management: Proper cable management, such as using cable ties or cable trays, can help prevent damage and reduce the risk of cable entanglement or stress on connectors.

- Testing: Periodically test your multi-conductor cables for continuity, resistance, and insulation integrity to ensure optimal performance and detect potential issues before they become critical.

- Environmental Factors: Be aware of the environmental conditions your cables are exposed to, such as temperature, humidity, and exposure to chemicals. Select cables with appropriate ratings for your specific environment to ensure long-term reliability.

Conclusion

Multi-conductor cables are a crucial component of modern electrical and communication systems, providing a versatile and efficient solution for transmitting multiple signals through a single cable. By understanding the key considerations for selecting, terminating, and maintaining multi-conductor cables, you can optimize the performance and reliability of your cable assemblies for various applications. Whether you’re working with control systems, telecommunications, or audio/video equipment, the right multi-conductor cable can make a significant difference in the success of your project.