Marine wire is designed for harsh environments, providing reliable power & connectivity in boats. Learn about types, applications, and best practices.

Understanding Marine Wire: Types, Applications, and Best Practices

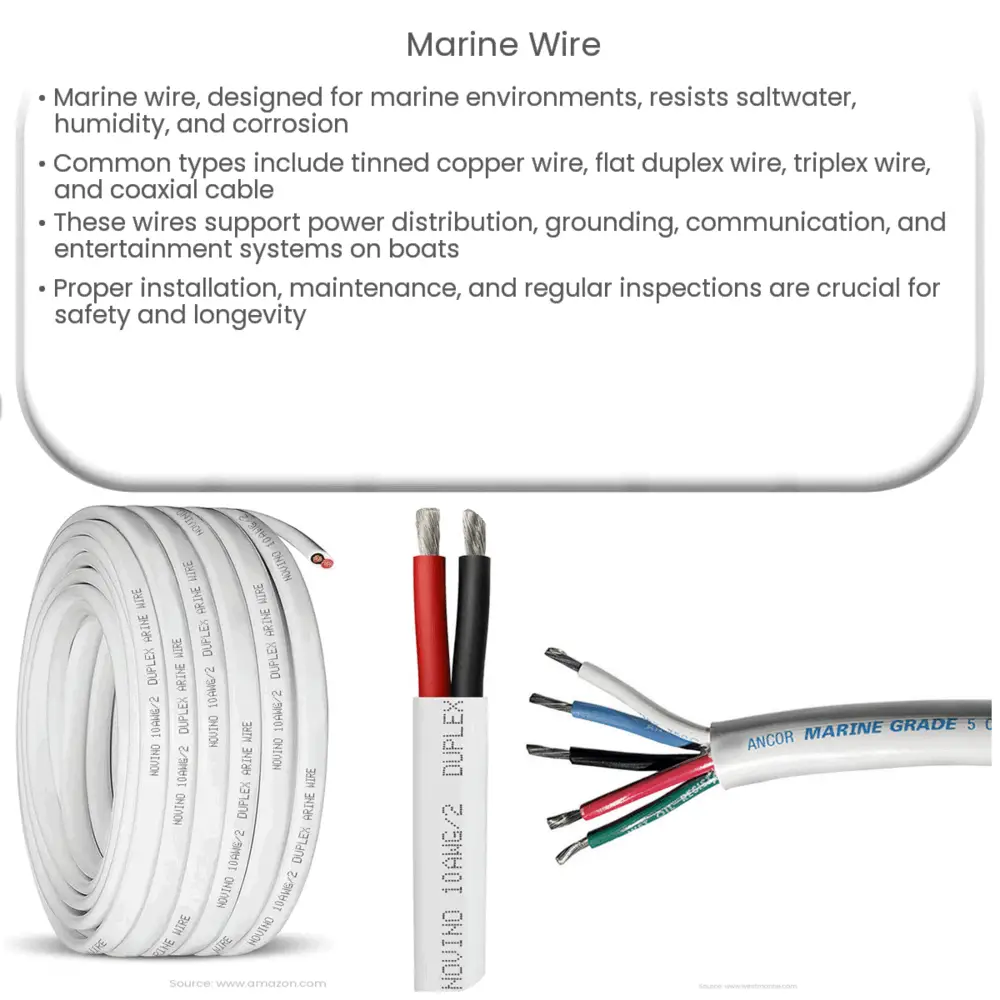

Introduction to Marine Wire

Marine wire, also known as boat wire or marine-grade wire, is a type of electrical wiring specifically designed for use in marine environments. It is constructed to withstand harsh conditions such as saltwater, humidity, and corrosion, making it ideal for various applications in boats, ships, and other marine vessels. This article will explore the different types of marine wire, their applications, and best practices for installation and maintenance.

Types of Marine Wire

There are several types of marine wire available, each suited for different applications and environmental conditions. The most common types include:

1. Tinned Copper Wire

Tinned copper wire is a popular choice for marine applications due to its high resistance to corrosion. It features a layer of tin that coats the copper strands, providing a barrier against moisture and saltwater. This type of wire is ideal for general marine wiring, including power distribution and grounding systems.

2. Flat Duplex Wire

Flat duplex wire is composed of two insulated conductors that are bonded together side by side, making it easier to manage and install. It is commonly used for DC applications, such as bilge pumps and other low-voltage devices.

3. Triplex Wire

Triplex wire, similar to duplex wire, consists of three insulated conductors bonded together. It is often used in AC systems on boats, such as shore power connections and generator wiring.

4. Coaxial Cable

Coaxial cable is a type of shielded cable used for transmitting radio frequency signals. In marine applications, it is commonly used for VHF radios, GPS antennas, and radar installations.

Marine Wire Applications

Marine wire plays a crucial role in the electrical systems of boats and other marine vessels. Some common applications include:

1. Power Distribution

Marine wire is used to distribute power from batteries and generators to various devices on board, such as navigation systems, lighting, and appliances. Properly sized and installed marine wire ensures efficient power distribution and prevents electrical issues.

2. Grounding Systems

A well-designed grounding system is essential for the safety and functionality of a boat’s electrical system. Marine wire is used to connect various components to a common ground, reducing the risk of electrical shock and protecting sensitive electronics from voltage fluctuations.

3. Communication and Navigation

Marine wire is used to connect communication and navigation equipment, such as VHF radios, GPS devices, and radar systems. It helps ensure reliable signal transmission and reception, even in harsh marine environments.

4. Audio and Entertainment Systems

Marine wire is also used to install and connect audio and entertainment systems on boats, such as speakers, amplifiers, and media players. Marine-grade wires provide better signal quality and durability, ensuring a more enjoyable and long-lasting entertainment experience.

Best Practices for Installation and Maintenance

Proper installation and maintenance of marine wire are essential for ensuring the safety and longevity of a boat’s electrical system. Here are some best practices to follow:

1. Choose the Right Wire Size and Type

Select the appropriate wire size and type based on the specific application, voltage, and current requirements. Using the wrong wire size or type can lead to overheating, voltage drops, and other electrical issues.

2. Use Marine-Grade Connectors and Terminals

Invest in high-quality, marine-grade connectors and terminals to ensure a secure and corrosion-resistant connection. This will help prevent electrical failures and improve the overall durability of the system.

3. Properly Seal and Protect Connections

Protect all wire connections from moisture and corrosion by using heat shrink tubing, adhesive-lined connectors, or liquid electrical tape. Regularly inspect connections for signs of wear or damage and promptly address any issues.

4. Secure and Organize Wiring

Secure and organize wires using cable clamps, zip ties, or wire loom to prevent chafing and damage from vibration or movement. This will also make it easier to troubleshoot and maintain the electrical system in the future.

5. Regularly Inspect and Maintain Wiring

Perform regular inspections of your boat’s wiring for signs of damage, corrosion, or wear. Replace any damaged or worn wires promptly to prevent electrical failures and potential hazards.

Conclusion

Marine wire is a critical component of a boat’s electrical system, providing power and connectivity to various devices and systems. By understanding the different types of marine wire, their applications, and best practices for installation and maintenance, boat owners can ensure the safety, reliability, and longevity of their electrical systems. Always use marine-grade wiring, connectors, and terminals, and regularly inspect and maintain your wiring to keep your vessel safe and functional in harsh marine environments.