PVC insulated wire offers excellent electrical insulation, flexibility, and durability, making it ideal for various industries like construction, electronics, and telecommunications.

PVC Insulated Wire: A Comprehensive Overview

Introduction to PVC Insulated Wire

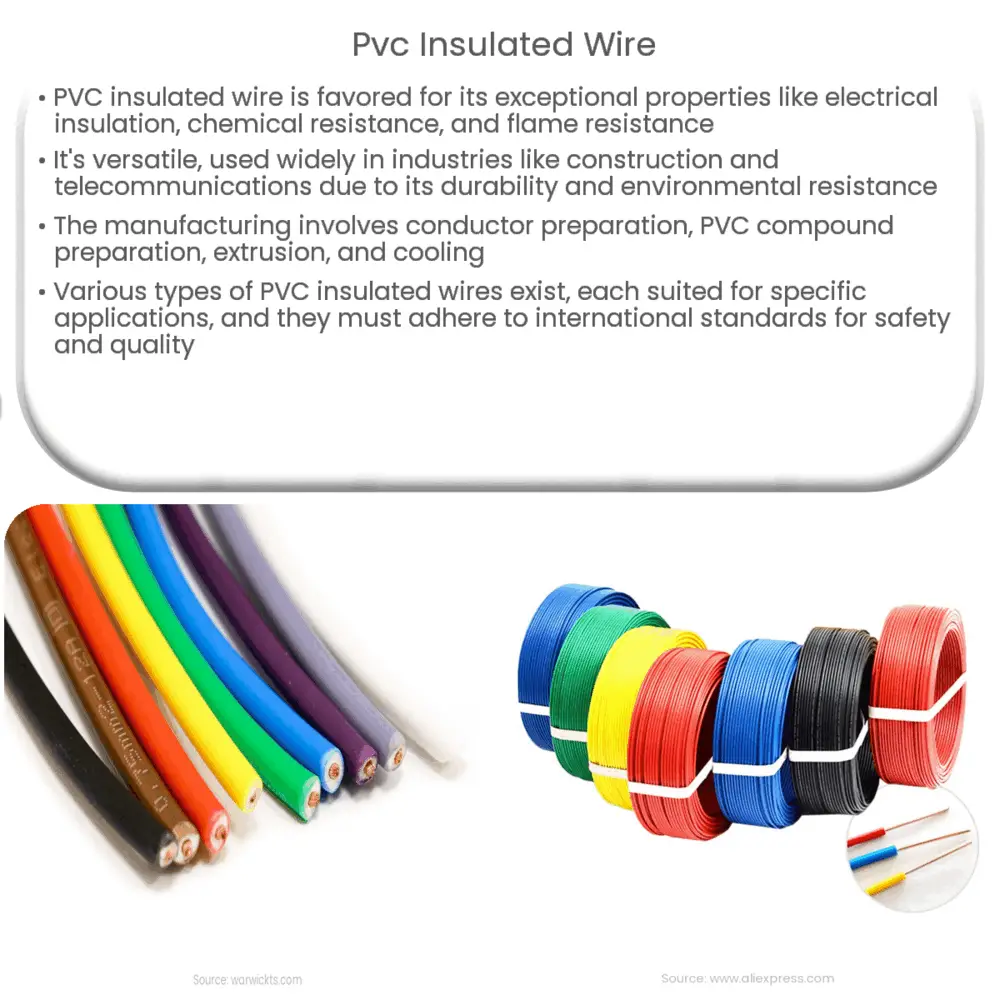

Polyvinyl chloride (PVC) insulated wire has become a popular choice in various industries, thanks to its advantageous properties. PVC is a synthetic plastic polymer that offers excellent insulation, durability, and resistance to various environmental factors. As a result, PVC insulated wire is widely used in electrical and communication applications. This article will discuss the characteristics, advantages, and applications of PVC insulated wire, as well as its manufacturing process.

Characteristics of PVC Insulated Wire

PVC insulated wire exhibits several key characteristics that make it an attractive choice for many applications:

- Electrical Insulation: PVC provides excellent electrical insulation, ensuring that the current flows smoothly and safely through the wire.

- Chemical Resistance: PVC insulated wires are resistant to chemicals, including acids, alkalis, and solvents, which helps prevent wire degradation.

- Flame Resistance: PVC has inherent flame resistance, which is crucial in preventing the spread of fire in electrical installations.

- Flexibility: PVC insulation offers flexibility, making it easier to install and maneuver wires in tight spaces.

- Cost-effective: PVC insulated wires are generally more affordable than other insulated wire types, making them an attractive option for budget-conscious projects.

Advantages of PVC Insulated Wire

There are several advantages associated with using PVC insulated wire, which contribute to its widespread adoption:

- Wide Range of Applications: PVC insulated wires can be used in various industries, such as construction, electronics, telecommunications, and automotive.

- Longevity and Durability: The chemical and physical properties of PVC provide excellent protection for the conductive core, prolonging the wire’s service life and ensuring reliable performance.

- Environmental Resistance: PVC insulated wire can withstand exposure to UV rays, moisture, and temperature changes, making it suitable for both indoor and outdoor applications.

- Easy Installation: The flexibility of PVC insulation simplifies wire installation, reducing labor costs and minimizing the risk of damage during the process.

PVC Insulated Wire Manufacturing Process

The manufacturing process for PVC insulated wire typically involves the following steps:

- Conductor Preparation: The process begins with preparing the conductive core, usually made of copper or aluminum. This core is either drawn into a single wire or stranded together to create the desired conductor size.

- PVC Compound Preparation: PVC resin, along with additives like plasticizers, stabilizers, and pigments, is mixed to create the desired insulation properties and color.

- Extrusion: The PVC compound is then heated and extruded around the conductor, forming a uniform layer of insulation.

- Cooling and Coiling: The insulated wire is cooled, either through air or water, and coiled onto a spool or reel for packaging and shipping.

Types of PVC Insulated Wire

There are several types of PVC insulated wire, catering to different applications and requirements:

- Single-core PVC Insulated Wire: These wires consist of a single conductor with PVC insulation and are commonly used for low voltage electrical installations in residential and commercial settings.

- Multi-core PVC Insulated Wire: These wires have multiple conductors, each insulated with PVC, and are typically used for power transmission and control circuits in industrial applications.

- PVC Insulated Flexible Wire: These wires are specifically designed for high flexibility and are suitable for applications requiring frequent bending, such as in machinery, robotics, and portable devices.

- PVC Insulated Coaxial Cable: Coaxial cables consist of a central conductor surrounded by a tubular insulating layer and an outer conductor, usually made of braided or woven wire. PVC insulation is commonly used for both the inner and outer insulation layers in these cables, which are widely used for transmitting radio frequency signals in telecommunications and cable TV systems.

Standards and Specifications

PVC insulated wires must comply with various international and regional standards to ensure safety, quality, and performance. Some of the most common standards include:

- IEC 60227: This international standard, published by the International Electrotechnical Commission (IEC), covers the general requirements and test methods for PVC insulated wires and cables.

- UL 83: Published by Underwriters Laboratories (UL), this standard specifies the requirements for thermoplastic-insulated wires and cables, including PVC insulated wires, intended for use in the United States.

- BS 6004: The British Standard (BS) 6004 outlines the requirements for PVC insulated, non-armored cables for voltages up to and including 450/750V, intended for use in the United Kingdom.

- VDE 0281: This German standard, published by the Association for Electrical, Electronic, and Information Technologies (VDE), specifies the requirements for PVC insulated single-core and multi-core wires.

Conclusion

PVC insulated wire is a versatile and cost-effective solution for various electrical and communication applications. Its characteristics, such as excellent electrical insulation, chemical resistance, flame resistance, and flexibility, make it a popular choice for both indoor and outdoor installations. By understanding the different types of PVC insulated wire, their manufacturing process, and relevant standards, users can select the most appropriate product for their specific needs and ensure a safe, reliable, and high-quality installation.