Explore the role, types, and usage of insulation resistance testers in electrical maintenance, with tips on safe operation and selection.

Introduction to Insulation Resistance Testers

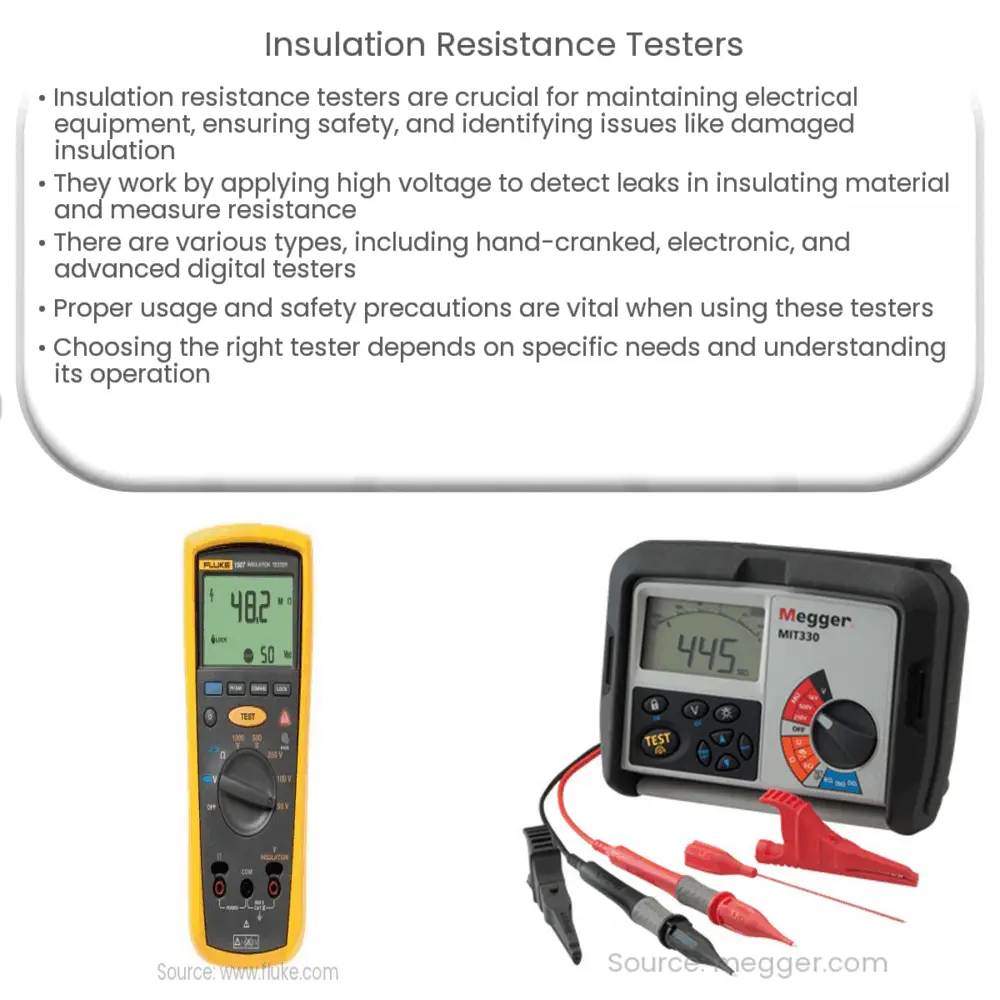

Insulation resistance testers, often referred to as ‘megohmmeters’ or ‘meggers,’ are indispensable tools in any electrical equipment maintenance and testing regimen. These devices are specifically designed to measure the resistance that electrical insulation materials offer to current flow. Consequently, they help ensure safety, efficiency, and longevity of electrical systems by identifying problems such as damaged insulation or excessive moisture.

How Insulation Resistance Testers Work

Insulation resistance testers operate by applying a higher than normal voltage—often between 250 and 5000 volts—to an electrical device’s conductor. The high voltage applied helps to identify any leaks present in the insulating material. The tester measures the amount of current that can leak across this insulation barrier and displays it as a resistance value, typically in megaohms or gigaohms.

- Megohm: One megohm is equal to 1,000,000 ohms, represented as 1MΩ.

- Gigohm: One gigohm equals 1,000,000,000 ohms, represented as 1GΩ.

The higher the resistance, the better the insulating material is at preventing current leakage, which translates to better safety and performance.

Types of Insulation Resistance Testers

There are various types of insulation resistance testers available in the market, each with its unique features and uses.

- Hand-Cranked Insulation Testers: These are the oldest types of insulation testers. They are manually operated and do not require a power source, making them handy in remote areas where power availability is a challenge.

- Electronic Insulation Testers: They are battery-operated devices that offer a wide range of testing voltages. They are convenient, easy to use, and offer a higher degree of measurement accuracy.

- Advanced Insulation Testers: These testers are digital, providing more accurate and detailed results. They can also record and store test results for future reference and analysis, a valuable feature for preventive maintenance programs.

Choosing the right insulation tester depends on your specific requirements, including the nature of the devices you’ll be testing, the environment you’re working in, and your budget. In the next part of this article, we’ll explore the process of using an insulation resistance tester, important safety considerations, and key factors to consider when purchasing one.

Using an Insulation Resistance Tester

Before using an insulation resistance tester, ensure the equipment under test is de-energized and disconnected from any power source. Also, ensure that you’re wearing the proper personal protective equipment. Once safety measures are in place, here’s a simplified step-by-step process:

- Connect the tester leads to the equipment: One lead to the conductor (equipment under test) and the other to the ground (earth).

- Set the desired test voltage on the tester. The voltage level depends on the type and rating of the insulation being tested.

- Activate the tester to apply the voltage. The tester then measures the resistance of the insulation and provides a reading.

- Interpret the reading. A higher reading indicates better insulation quality.

It’s important to note that testing should be done under similar temperature conditions each time, as resistance can vary with temperature.

Safety Considerations

When using insulation resistance testers, safety should be the utmost priority. These testers use high voltage, and if mishandled, can result in electrical shock or damage to equipment. Be sure to understand and follow all safety instructions provided by the tester manufacturer.

Choosing an Insulation Resistance Tester

When purchasing an insulation resistance tester, consider factors such as the tester’s voltage range, accuracy, durability, and data logging capabilities. Additionally, consider the device’s safety features, such as automatic discharge of test voltage and warning indicators for live circuits.

Conclusion

In conclusion, insulation resistance testers are vital tools in the maintenance and safety of electrical equipment. They provide an effective way to diagnose and prevent insulation-related failures, enhancing the reliability and lifespan of electrical systems. Whether it’s a simple hand-cranked model or a sophisticated digital device, the key lies in choosing a tester that meets your specific needs and applying it correctly and safely. By understanding the role and operation of these devices, you can make more informed decisions in your electrical maintenance strategy.