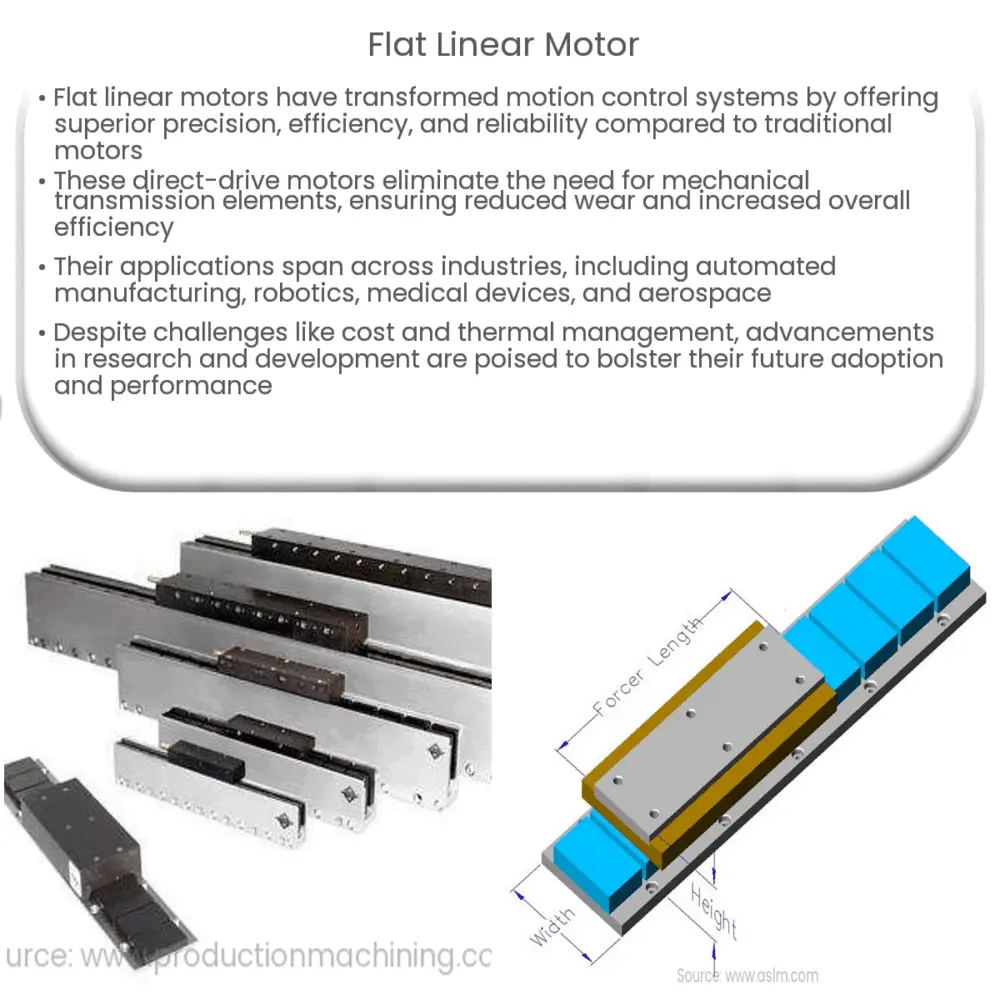

Flat linear motors provide precise, efficient, and reliable motion control by eliminating mechanical transmission components.

Flat Linear Motors: Revolutionizing Motion Control

In recent years, flat linear motors have emerged as a game-changing technology in motion control systems. These innovative devices offer numerous advantages over traditional motors, including increased efficiency, precision, and reliability. In this article, we will explore the fundamentals of flat linear motors, their applications, and how they are revolutionizing the world of motion control.

What is a Flat Linear Motor?

A flat linear motor is a type of direct-drive motor that generates linear motion without the need for any mechanical transmission elements such as ball screws, belts, or gears. The motor’s design consists of two primary components: the stator, which is stationary and generates a magnetic field, and the mover, which is the moving part that translates the magnetic force into linear motion.

One key feature of flat linear motors is their low-profile design, which enables them to be integrated into compact and space-constrained applications. Moreover, their direct-drive mechanism eliminates the need for mechanical transmission components, resulting in reduced wear and tear, lower maintenance requirements, and higher overall efficiency.

Advantages of Flat Linear Motors

Flat linear motors offer several advantages over traditional linear motion systems:

- Higher precision and accuracy: By eliminating mechanical transmission components, flat linear motors can achieve extremely precise and accurate motion control, with less backlash and mechanical errors.

- Improved efficiency: Direct-drive systems minimize energy loss through mechanical friction, resulting in higher overall efficiency.

- Increased reliability and reduced maintenance: With fewer moving parts, flat linear motors are less prone to wear and tear, increasing their overall reliability and reducing the need for maintenance.

- Faster response times: Direct-drive systems enable quicker acceleration and deceleration, providing faster response times and improved dynamic performance.

- Silent operation: By eliminating mechanical noise from gears and other transmission components, flat linear motors can operate with minimal noise, making them suitable for quiet environments such as laboratories and medical facilities.

Applications of Flat Linear Motors

Flat linear motors are employed in a wide range of applications across various industries, including:

- Automated manufacturing and assembly: The precision and efficiency of flat linear motors make them ideal for use in high-speed automated production lines, where they can perform tasks such as pick-and-place, sorting, and packaging.

- Robotics: Flat linear motors can be used in robotic arms and other motion control systems to provide precise and agile movements, enabling robots to perform tasks with increased accuracy and speed.

- Medical devices: The compact design and quiet operation of flat linear motors make them suitable for use in medical devices, such as surgical robots and diagnostic equipment.

- Aerospace and defense: The reliability and low-maintenance requirements of flat linear motors make them an attractive option for critical applications in the aerospace and defense sectors.

In conclusion, flat linear motors are transforming the way motion control systems are designed and implemented across various industries. By offering improved precision, efficiency, and reliability, these innovative devices are poised to play a significant role in the future of automation and robotics.

Challenges and Limitations of Flat Linear Motors

Despite their numerous advantages, flat linear motors also present some challenges and limitations:

- Cost: Flat linear motors can be more expensive than traditional linear motion systems, primarily due to the complexity of their design and the materials used, such as high-performance magnets.

- Thermal management: Flat linear motors can generate considerable heat during operation, which may necessitate the use of cooling systems to maintain optimal performance and prevent overheating.

- Magnetic shielding: The strong magnetic fields generated by flat linear motors can interfere with sensitive electronics or other equipment, requiring the use of magnetic shielding to minimize potential disruptions.

Overcoming Challenges and the Future of Flat Linear Motors

Researchers and engineers continue to develop innovative solutions to address the challenges associated with flat linear motors. Some of these advancements include:

- Cost reduction: The ongoing development of more affordable, high-performance magnetic materials, and improved manufacturing techniques are expected to help reduce the cost of flat linear motors in the future.

- Advanced thermal management: New cooling technologies, such as integrated liquid cooling systems, are being developed to effectively dissipate heat and maintain optimal motor performance.

- Magnetic shielding improvements: Progress in the design and manufacturing of magnetic shielding materials will help minimize the impact of magnetic interference on surrounding equipment.

As these challenges are addressed, the adoption of flat linear motors across various industries is expected to increase, further driving innovation and improvements in their design and performance.

Conclusion

Flat linear motors have emerged as a revolutionary technology in the field of motion control, offering numerous advantages over traditional linear motion systems. Their high precision, efficiency, and reliability make them ideal for a wide range of applications in industries such as automated manufacturing, robotics, medical devices, and aerospace and defense.

While challenges such as cost, thermal management, and magnetic shielding remain, ongoing research and development efforts are likely to overcome these limitations and expand the potential applications for flat linear motors. As the technology continues to mature, we can expect flat linear motors to play an increasingly significant role in the future of automation and robotics, enabling new levels of precision, speed, and efficiency in motion control systems.