Iron-core linear motors provide high force density, precision, and efficiency in automation, enabling advancements across various industries.

Iron-Core Linear Motors: Revolutionizing Automation and Motion Control

Linear motors have become a cornerstone technology in the world of automation and motion control, providing high precision and rapid movement in a wide range of applications. One of the most effective types of linear motors is the iron-core linear motor, offering unrivaled performance and efficiency. In this two-part article, we will delve into the inner workings of iron-core linear motors, their advantages, and their applications.

What is an Iron-Core Linear Motor?

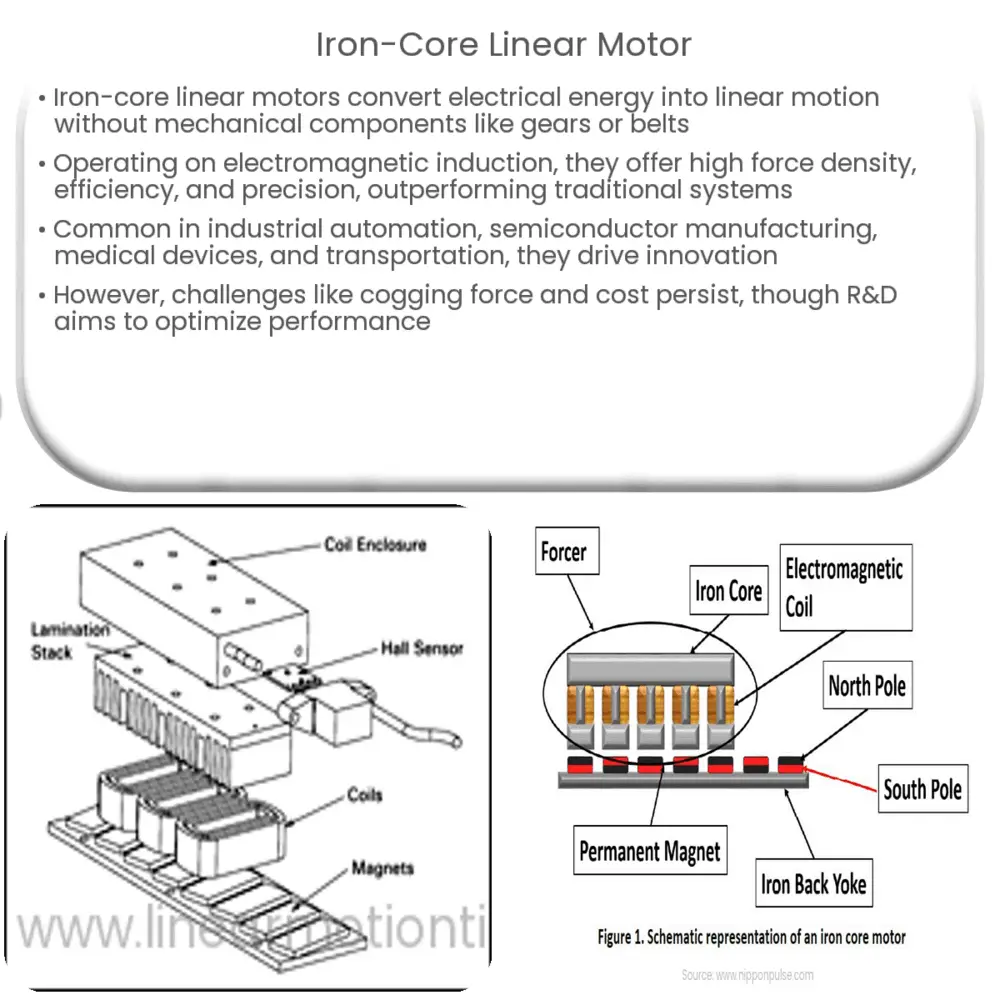

An iron-core linear motor is a type of electromagnetic motor that converts electrical energy directly into linear motion without the need for mechanical transmission components such as gears, belts, or pulleys. It consists of a primary part, known as the ‘forcer,’ and a secondary part, called the ‘track’ or ‘platen.’ The forcer contains the windings, which generate a magnetic field when an electric current is applied, while the track is made of laminated iron cores with alternating north and south magnetic poles.

How Does an Iron-Core Linear Motor Work?

Iron-core linear motors operate on the principle of electromagnetic induction. When an alternating current is applied to the windings in the forcer, it generates a magnetic field that interacts with the magnetic field created by the permanent magnets in the track. This interaction creates a force that moves the forcer along the track, producing linear motion.

The motion can be precisely controlled by adjusting the current supplied to the windings, allowing for smooth acceleration, deceleration, and accurate positioning. A linear encoder, typically mounted on the forcer, provides feedback on the motor’s position, enabling closed-loop control for enhanced precision.

Advantages of Iron-Core Linear Motors

Iron-core linear motors offer numerous benefits over other linear motor types and traditional mechanical transmission systems:

- High force density: Due to the presence of an iron core, these motors have a higher force density compared to other linear motor types, such as ironless linear motors. This enables them to generate more force per unit of size, making them suitable for applications requiring high acceleration and force.

- High efficiency: The use of laminated iron cores in the track minimizes eddy current losses, resulting in higher overall efficiency compared to ironless motors.

- Excellent thermal performance: The iron core’s high thermal conductivity allows for efficient heat dissipation, enabling these motors to operate at higher power levels and duty cycles without overheating.

- Direct drive: By eliminating mechanical transmission components, iron-core linear motors offer reduced backlash, wear, and maintenance, resulting in improved reliability and lifespan.

- High precision: The combination of direct drive and closed-loop control enables iron-core linear motors to achieve high levels of accuracy and repeatability in positioning applications.

Applications of Iron-Core Linear Motors

Iron-core linear motors have found their way into a variety of industries and applications, thanks to their performance and reliability:

- Industrial automation: In manufacturing and assembly lines, iron-core linear motors facilitate precise positioning, high-speed motion, and improved throughput, making them ideal for pick-and-place robots, CNC machines, and automated material handling systems.

- Semiconductor manufacturing: These motors are widely used in the production of integrated circuits and other microelectronics, where high precision and cleanroom compatibility are crucial.

- Medical and biotechnology: Iron-core linear motors are used in medical devices such as surgical robots, imaging systems, and laboratory automation equipment, where accuracy, reliability, and sterility are paramount.

- Aerospace and defense: The high force density and precision of iron-core linear motors are essential for applications such as satellite positioning systems, missile guidance systems, and flight simulators.

- Transportation: Iron-core linear motors have been employed in magnetic levitation (maglev) trains, offering high-speed, low-maintenance, and energy-efficient transportation.

Future Developments and Challenges

As industries continue to adopt iron-core linear motors, research and development efforts are focused on improving their performance, efficiency, and cost-effectiveness. Some of the areas under investigation include:

- Advanced materials: The development of new magnetic materials and manufacturing techniques promises to enhance the force density, efficiency, and thermal performance of iron-core linear motors.

- Higher precision: Improvements in encoder technology, control algorithms, and motor design aim to push the limits of precision and repeatability for these motors.

- Integration: Efforts are being made to simplify the integration of iron-core linear motors into existing systems and machinery, reducing the cost and complexity of implementation.

Despite their many advantages, iron-core linear motors also face some challenges. The presence of an iron core can lead to increased cogging force, which may cause unwanted vibrations and negatively impact positioning accuracy. Moreover, iron-core linear motors can be more expensive than alternative technologies, such as ironless linear motors or traditional mechanical transmission systems. Nonetheless, ongoing research and development continue to address these concerns and optimize the performance of iron-core linear motors.

Conclusion

Iron-core linear motors have proven to be a game-changer in the world of automation and motion control, providing high force density, efficiency, and precision. As industries continue to adopt this technology, we can expect further advancements and improvements, solidifying the iron-core linear motor’s position as a key driver of innovation and productivity.