Linear synchronous motors (LSMs) are efficient, precise, and low-maintenance motors that utilize electromagnetism for direct linear motion in various applications.

Linear Synchronous Motor (LSM) – Part 1

Introduction

Linear synchronous motors (LSMs) are a type of linear motor that leverage the principles of electromagnetism to generate linear motion directly without the need for mechanical conversion. They have been utilized in various applications, including transportation, material handling, and robotics. In this article, we will explore the working principles, advantages, and applications of LSMs.

Working Principles of LSMs

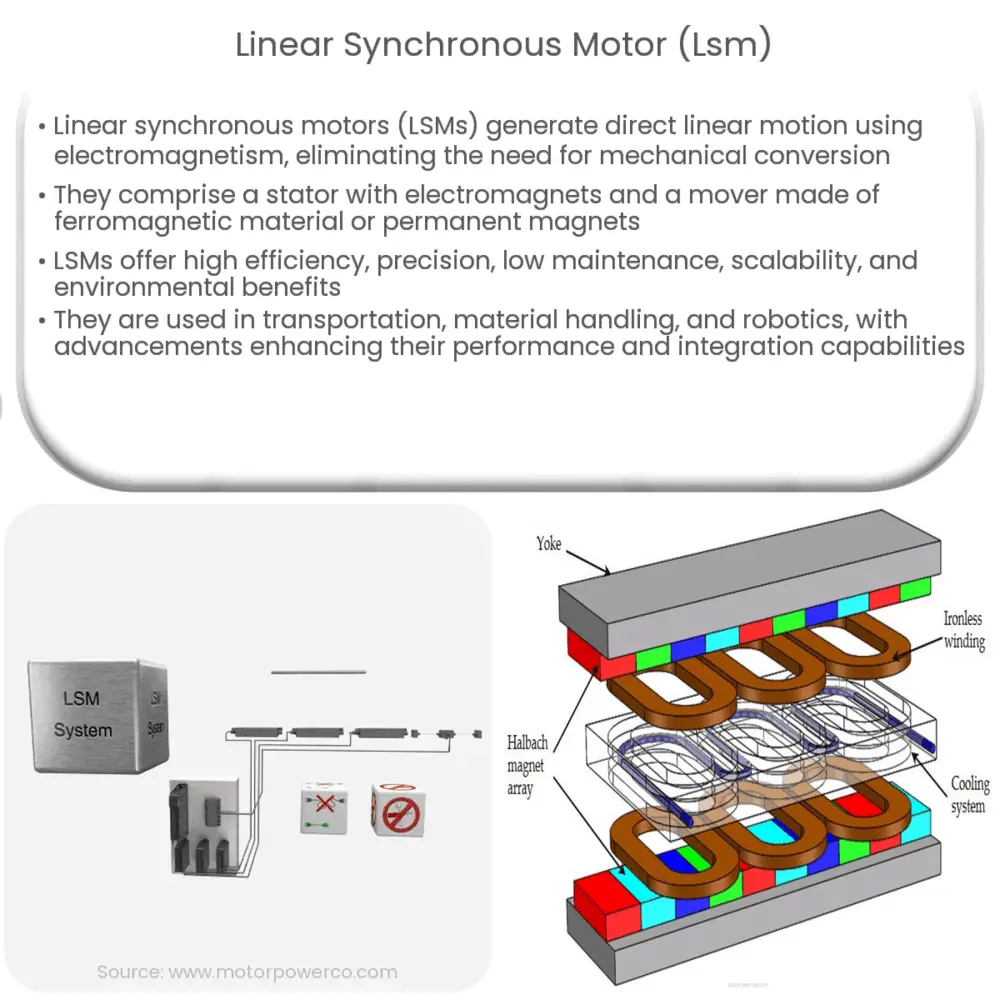

LSMs comprise two main components: a primary part called the stator, which houses an array of electromagnets, and a secondary part called the mover or rotor, which is made of a ferromagnetic material or contains permanent magnets. The stator generates a traveling magnetic field when it receives a three-phase alternating current, and the mover follows this field, creating a linear movement.

By precisely controlling the current’s frequency and phase, the LSM can generate precise and controlled linear motion without the need for intermediate mechanical components, such as gears or belts. The absence of these mechanical components reduces friction and wear, resulting in improved efficiency and reduced maintenance requirements.

Advantages of LSMs

There are several advantages to using LSMs in various applications:

- High Efficiency: LSMs have fewer mechanical components, which reduces friction and energy losses. This results in increased efficiency compared to other linear motion systems.

- High Precision and Control: The linear motion of LSMs can be accurately controlled by adjusting the current’s frequency and phase. This allows for precise positioning and excellent speed control, making them suitable for applications that require high precision.

- Low Maintenance: The absence of mechanical components like gears and belts means that LSMs have fewer parts that can wear out or require replacement, resulting in lower maintenance costs and longer service life.

- Scalability: LSMs can be designed in various sizes and power ratings, making them adaptable to a wide range of applications, from small-scale robotic systems to large transportation projects.

- Environmentally Friendly: Due to their high efficiency, LSMs consume less energy, reducing their environmental impact. Furthermore, they produce less noise and vibration, improving the overall performance and user experience.

Applications of LSMs

LSMs have been employed in various industries and applications, including:

- Transportation: LSMs are used in modern transportation systems like maglev trains, where they enable frictionless, high-speed travel.

- Material Handling: In manufacturing and logistics facilities, LSMs are used for the precise and efficient movement of goods along assembly lines and conveyors.

- Robotics: LSMs are employed in robotic systems that require accurate positioning and smooth linear motion, such as pick-and-place robots in manufacturing or medical applications.

In the second part of this article, we will delve deeper into the different types of LSMs, their design considerations, and recent advancements in LSM technology.

Linear Synchronous Motor (LSM) – Part 2

Types of LSMs

LSMs can be classified into two main categories based on their mover design:

- Permanent Magnet LSM: In this type of LSM, the mover contains permanent magnets. The stator generates a traveling magnetic field, which interacts with the permanent magnets, causing the mover to follow the magnetic field and produce linear motion. These motors typically offer higher force densities and are more commonly used in applications requiring high precision and performance.

- Electrically Excited LSM: In this type, the mover is made of ferromagnetic material, and the stator windings are responsible for both generating the magnetic field and inducing magnetic poles in the mover. Electrically excited LSMs can have a lower cost and be more flexible in design, but they generally have lower force density compared to permanent magnet LSMs.

Design Considerations

When designing an LSM, several factors need to be considered to ensure optimal performance:

- Magnet Type: The choice between permanent magnets and electrically excited movers depends on the specific requirements of the application, such as force density, cost, and design flexibility.

- Cooling System: LSMs can generate significant heat, especially at high speeds or under heavy loads. A well-designed cooling system is crucial for maintaining the motor’s performance and preventing overheating.

- Control System: A robust control system is essential for precise control of the motor’s position and speed. This typically involves a combination of feedback devices, such as encoders, and advanced control algorithms.

- Mechanical Integration: The integration of the LSM into the overall mechanical system must be carefully considered to minimize alignment errors, mechanical resonance, and other factors that could degrade the motor’s performance.

Recent Advancements in LSM Technology

LSM technology has seen significant advancements in recent years, driven by the increasing demand for efficient, precise, and environmentally friendly motion solutions. Some notable developments include:

- Higher Force Densities: Improvements in magnet materials and motor designs have enabled LSMs to achieve higher force densities, making them suitable for a wider range of applications.

- Improved Control Algorithms: Advanced control techniques, such as model predictive control and adaptive control, have been developed to enhance the performance and precision of LSMs.

- Integration with IoT: The integration of LSMs with the Internet of Things (IoT) has enabled better monitoring, diagnostics, and predictive maintenance, further enhancing their reliability and reducing maintenance costs.

Conclusion

Linear synchronous motors offer a highly efficient, precise, and environmentally friendly solution for various linear motion applications. With ongoing advancements in magnet materials, control algorithms, and IoT integration, LSMs are expected to play an increasingly significant role in transportation, material handling, robotics, and other industries.