Infrared level sensors use reflected infrared light to accurately measure liquid and solid levels in various industries, offering non-contact, reliable, and real-time monitoring.

Infrared Level Sensor: Applications and Advantages

In recent years, level sensing technologies have become increasingly important in a variety of industries, ranging from agriculture to oil and gas. One of the most effective and reliable types of level sensors is the infrared level sensor. In this article, we will explore the principles behind infrared level sensors, their applications, and the advantages they offer over other sensing technologies.

Principles of Infrared Level Sensing

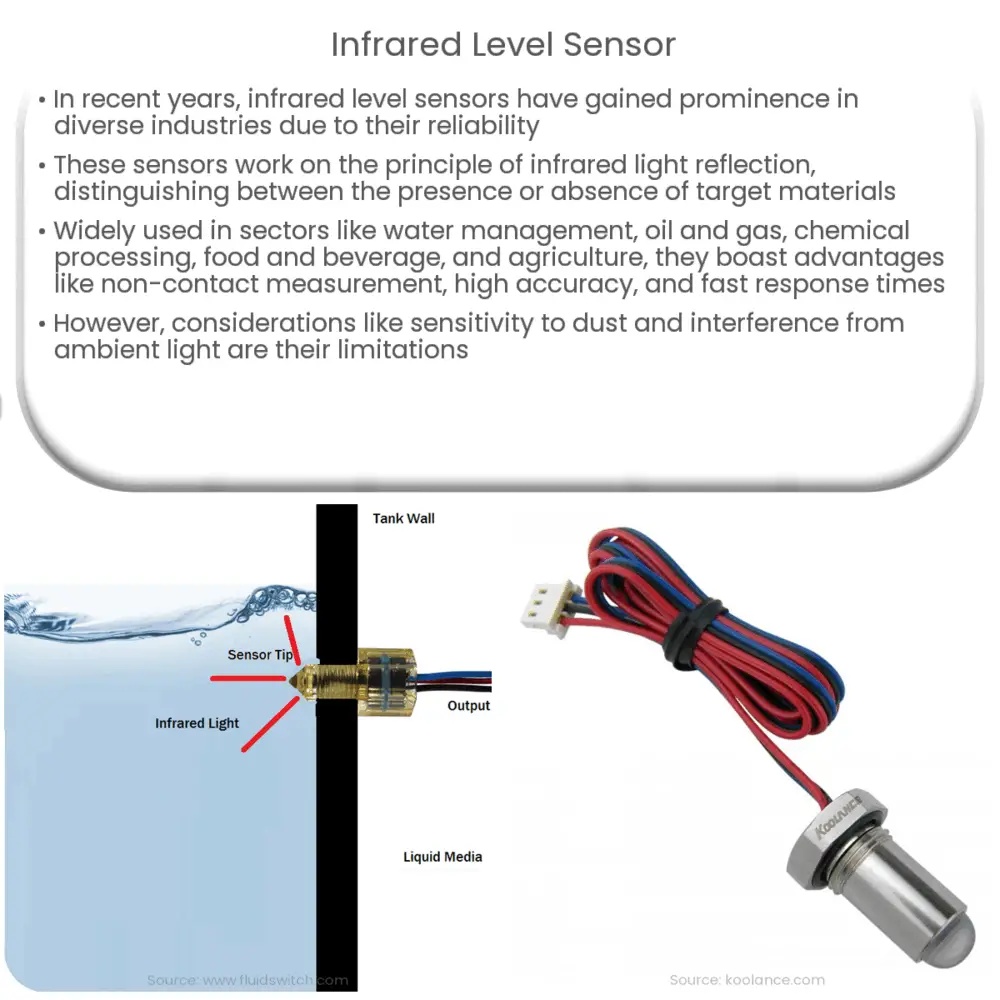

Infrared level sensors operate on the principle of infrared light reflection. An infrared light source, typically an LED, emits a beam of infrared light towards a target surface. When the light beam encounters the target surface, it is reflected back towards a detector, usually a photodiode. By measuring the intensity of the reflected light, the sensor can determine the presence or absence of a target material, such as a liquid or solid, in the detection area.

There are two primary types of infrared level sensors: through-beam and reflective. In through-beam sensors, the transmitter and receiver are positioned opposite each other, with the target material passing between them. This type of sensor is highly accurate but may require more complex installation and alignment. Reflective sensors, on the other hand, have the transmitter and receiver positioned adjacent to each other, with the target material reflecting the infrared light back to the receiver. Reflective sensors are more compact and easier to install but may be less accurate in certain conditions.

Applications of Infrared Level Sensors

Infrared level sensors are utilized in various industries and applications, including:

- Water and wastewater management: Monitoring and controlling water levels in reservoirs, tanks, and sumps, as well as detecting leaks and overflows.

- Oil and gas: Measuring liquid levels in storage tanks, pipelines, and process vessels, ensuring accurate inventory management and preventing spills.

- Chemical processing: Monitoring levels of aggressive, corrosive, or high-temperature liquids in tanks and reactors.

- Food and beverage: Ensuring proper filling levels in containers, bottles, and vats, and detecting the presence of liquid or solid ingredients in processing lines.

- Agriculture: Monitoring irrigation systems, water storage, and livestock drinking troughs to ensure optimal water use and animal health.

Advantages of Infrared Level Sensors

Infrared level sensors offer numerous benefits over other types of sensing technologies, such as ultrasonic, capacitive, and float-based sensors:

- Non-contact measurement: Infrared sensors do not require contact with the target material, reducing the risk of contamination, wear, and corrosion.

- High accuracy: Infrared level sensors can provide precise and reliable measurements, even in challenging conditions such as turbulence or foam.

- Fast response times: Infrared sensors can quickly detect changes in level, enabling real-time monitoring and control.

- Wide operating temperature range: Infrared sensors can function in extreme temperatures, making them suitable for a variety of applications and environments.

- Simple installation and maintenance: Infrared level sensors are generally compact and easy to install, and typically require minimal maintenance.

Limitations of Infrared Level Sensors

While infrared level sensors offer numerous advantages, they also have some limitations that should be considered when selecting the appropriate sensing technology for a specific application:

- Sensitivity to dust and dirt: Accumulation of dust or dirt on the sensor’s optical components can lead to reduced accuracy or false readings. Regular cleaning and maintenance may be required to ensure reliable operation.

- Interference from ambient light: Infrared sensors can be susceptible to interference from ambient light sources, such as sunlight or other artificial lights. Proper shielding or filtering may be necessary to minimize these effects.

- Material compatibility: Infrared sensors may not perform optimally with certain materials, such as those with low reflectivity or high absorption of infrared light. In these cases, alternative sensing technologies may be more suitable.

- Limited range: The sensing range of infrared level sensors is typically shorter than that of other technologies, such as ultrasonic sensors. This may limit their usefulness in certain applications where longer-range sensing is required.

Selecting the Right Infrared Level Sensor

When choosing an infrared level sensor for a specific application, several factors should be considered to ensure optimal performance and reliability:

- Range and resolution: Select a sensor with an appropriate sensing range and resolution to meet the requirements of the application.

- Material properties: Consider the target material’s reflectivity, absorption, and other optical properties to ensure compatibility with the sensor.

- Environmental conditions: Evaluate the operating temperature, humidity, and other environmental factors to select a sensor that can withstand these conditions.

- Installation and maintenance: Choose a sensor with a form factor and mounting options that allow for easy installation and maintenance.

- Cost and reliability: Balance the cost of the sensor with its expected performance, durability, and long-term reliability.

Conclusion

Infrared level sensors provide an effective and reliable means of measuring liquid and solid levels in a wide range of applications and industries. By understanding the principles, applications, advantages, and limitations of these sensors, users can select the most appropriate technology for their specific needs. With proper selection and implementation, infrared level sensors can offer accurate, real-time monitoring and control, contributing to improved efficiency, safety, and overall performance in numerous processes.