Eutectic solder is a versatile alloy used in electronics, aerospace, automotive, and medical industries due to its unique melting and solidification properties.

Eutectic Solder: An Overview

Eutectic solder is a unique alloy used in various industries, primarily for its advantageous melting properties. In this article, we will delve into the composition, applications, and benefits of eutectic solder, as well as the challenges associated with its use.

Composition of Eutectic Solder

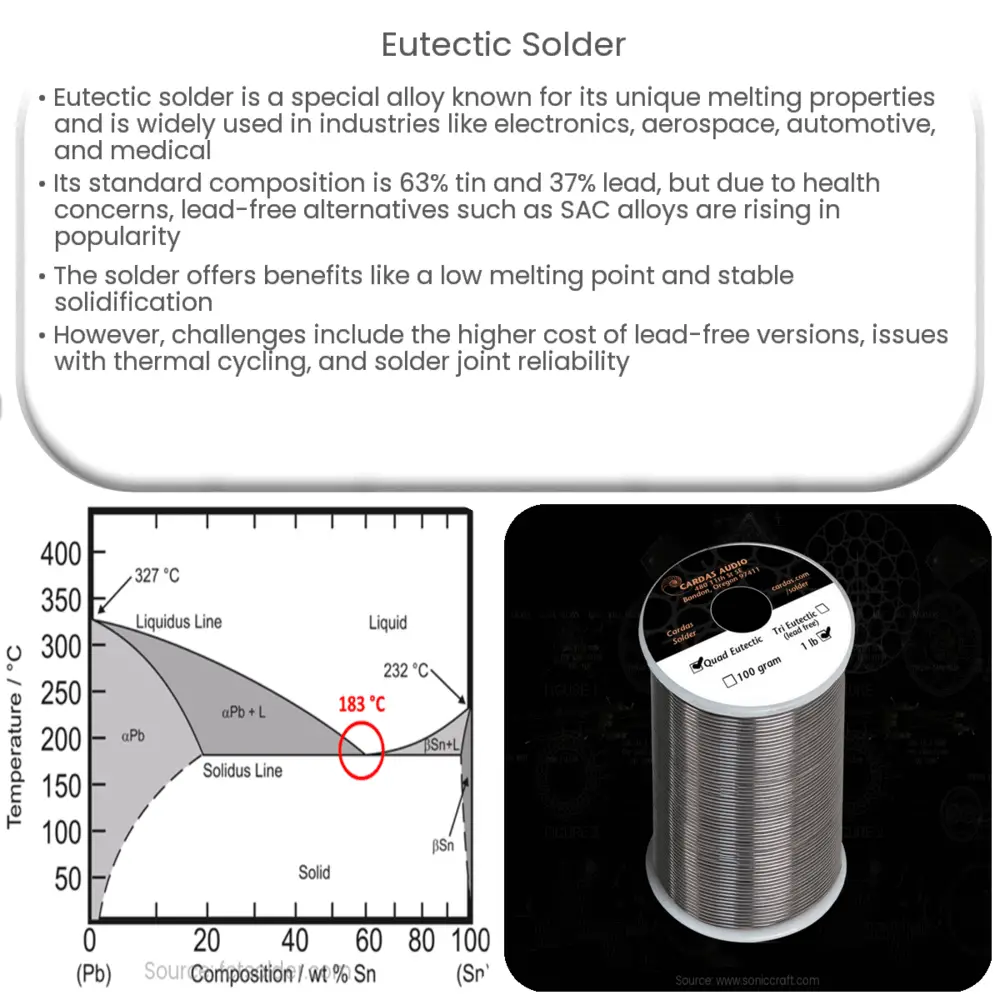

At its core, eutectic solder is a mixture of metals that form a eutectic alloy. A eutectic alloy is a mixture of two or more elements that melt and solidify at a single temperature. The most common eutectic solder is made from a combination of tin (Sn) and lead (Pb), with a 63% tin and 37% lead ratio. This specific alloy, often referred to as Sn63Pb37, has a melting point of 183°C (361°F) and is considered the industry standard for eutectic solder.

Due to environmental and health concerns related to lead, lead-free eutectic solders have become increasingly popular in recent years. Tin-silver-copper (SAC) alloys are the most common lead-free alternative. For example, the SAC305 alloy (96.5% tin, 3% silver, and 0.5% copper) is widely used due to its comparable performance and melting point of around 217-220°C (423-428°F).

Applications of Eutectic Solder

Eutectic solder is utilized across various industries due to its excellent melting and solidification properties. Some common applications include:

- Electronics: Eutectic solder is widely used for assembling printed circuit boards (PCBs) and connecting electronic components. Its low melting point and stable solidification process make it ideal for soldering delicate electronic components without causing damage.

- Aerospace: Eutectic solder is employed in aerospace applications due to its ability to maintain structural integrity and resist temperature fluctuations. It is particularly useful for assembling components in satellite and spacecraft systems.

- Automotive: In the automotive industry, eutectic solder is used to create strong, reliable connections in various electronic systems, such as engine control units and safety systems.

- Medical: Eutectic solder plays a vital role in the manufacturing of medical devices, such as pacemakers and hearing aids, where stable connections and minimal damage to sensitive components are essential.

Benefits of Eutectic Solder

There are several key benefits to using eutectic solder, which include:

- Low melting point: Eutectic solder’s low melting point enables it to be used in applications where high temperatures may damage sensitive components, such as electronics.

- Stable solidification process: The eutectic alloy solidifies at a single temperature, allowing for a uniform and stable connection, which is crucial for reliable performance in electronic devices.

- Lead-free alternatives: The availability of lead-free eutectic solders, such as SAC alloys, ensures compliance with environmental regulations and reduces health risks associated with lead exposure.

Challenges Associated with Eutectic Solder

Despite its numerous benefits, eutectic solder also presents certain challenges:

- Higher cost of lead-free alternatives: Lead-free eutectic solders, such as SAC alloys, are typically more expensive than traditional lead-based solders. This increased cost can be a barrier to adoption for some manufacturers.

- Thermal cycling: Repeated heating and cooling cycles can cause eutectic solder joints to become brittle and eventually fail. This is particularly concerning in applications where the soldered components are exposed to temperature fluctuations, such as in automotive or aerospace systems.

- Solder joint reliability: The reliability of eutectic solder joints depends on factors such as the cleanliness of the surfaces to be joined, the soldering technique used, and the quality of the solder itself. These factors must be carefully controlled to ensure reliable connections.

Conclusion

Eutectic solder is a versatile and widely used alloy in numerous industries due to its unique melting and solidification properties. While lead-based eutectic solders have been the industry standard for decades, the emergence of lead-free alternatives has addressed environmental and health concerns. Although eutectic solder offers several advantages, manufacturers must also consider the challenges it presents, such as the increased cost of lead-free alternatives, thermal cycling, and solder joint reliability. By understanding the properties, applications, benefits, and challenges of eutectic solder, engineers and manufacturers can make informed decisions about its use in their products and processes.

References

- J. W. Morris Jr., “Lead-free solders in microelectronics,” Materials Today, vol. 8, no. 6, pp. 18-25, 2005.

- N. N. Ekere, R. Bhatti, and M. Mallik, “The effects of solder paste and PCB surface finish chemistries on the wetting and solder joint reliability of SnAgCu solder on lead-free assemblies,” Journal of Materials Processing Technology, vol. 207, no. 1-3, pp. 173-186, 2008.

- K. Sweatman, T. Nishimura, and T. Saito, “Reliability of lead-free solder joints,” in Handbook of Electronic Assembly and A Guide to SMTA Certification, R. K. Ulrich and W. D. Greig, Eds. New York: McGraw-Hill, 2015, pp. 25.1-25.39.