Explore the importance of ESD simulators in electronics testing, their working principle, types, selection criteria, and the future of ESD testing.

Understanding ESD Simulators

Electrostatic Discharge (ESD) is a sudden flow of electricity between two objects caused by contact, an electrical short, or dielectric breakdown. This phenomenon, while commonly experienced in daily life (like when you feel a shock after walking on a carpet), can have a detrimental impact on sensitive electronic equipment. This is where ESD simulators come into play.

The Role of ESD Simulators

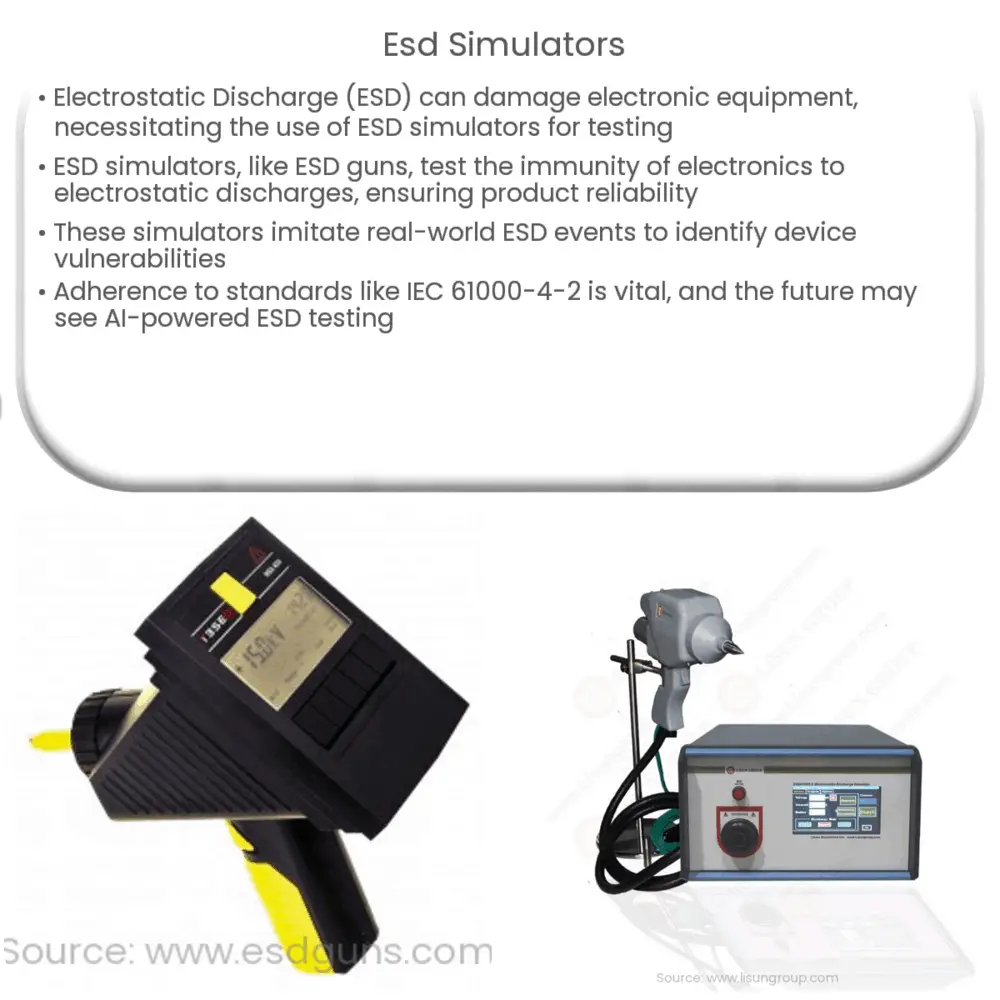

ESD simulators, also known as ESD guns, are specialized tools used in the field of electronics and electromagnetics to test the immunity of electronic devices against electrostatic discharges. These devices play a crucial role in ensuring that products are reliable and safe from ESD threats before they hit the market.

The Working Principle of ESD Simulators

ESD simulators work by generating an electrostatic discharge similar to a real-world ESD event. The simulated discharge is then applied to the device under test, allowing engineers to observe the device’s response and identify any potential areas of weakness.

- Discharge Modes: ESD simulators typically have two discharge modes – contact discharge and air discharge. In the contact discharge mode, the ESD simulator directly contacts the device under test, while in the air discharge mode, a discharge occurs through the air between the simulator and the device.

- Voltage Levels: The simulators can generate varying voltage levels to simulate different ESD events. These levels often range from a few hundred volts to several kilovolts, replicating common ESD threats in various environments.

ESD Standards and ESD Simulators

There are numerous standards guiding the ESD immunity tests, and ESD simulators are designed to comply with these. The most common standard is the IEC 61000-4-2, which provides guidelines on testing and measurement techniques for electrostatic discharge immunity testing. ESD simulators play a significant role in performing tests compliant with this and other similar standards, ensuring that devices can withstand ESD events as stipulated by the standard’s guidelines.

Types of ESD Simulators

There are various types of ESD simulators available in the market, each designed to suit different testing requirements. Some of the common types include handheld ESD simulators, modular ESD simulators, and automated ESD simulators. Choosing the right type of ESD simulator depends on several factors, including the device under test, the testing environment, and the specific ESD testing standards being adhered to.

Selection Criteria for ESD Simulators

Choosing an ESD simulator that fits your specific needs can be challenging. Here are a few considerations to keep in mind:

- Compliance with Standards: Ensure that the simulator is compliant with the relevant ESD immunity standards such as IEC 61000-4-2, ISO 10605, and others depending on your specific field of operation.

- Voltage Range: A wide voltage range provides more flexibility, enabling testing under various scenarios.

- Discharge Modes: Both contact and air discharge modes should be available to simulate different real-world scenarios.

- Usability: User-friendly interface, portability, and ergonomic design can enhance the efficiency of testing.

ESD Simulator Maintenance

Proper maintenance of ESD simulators is crucial to ensure their accuracy and reliability. This includes regular calibration in accordance with the manufacturer’s guidelines, and conducting preventive maintenance procedures to extend the life of the simulator. Also, consider investing in training for personnel using the simulator, as human errors can lead to inaccurate test results.

The Future of ESD Testing

As electronic devices become more advanced and miniaturized, the need for effective ESD testing and simulation increases. Recent trends point towards automated ESD testing and simulation, with the goal of minimizing human error and ensuring more accurate and repeatable tests. Furthermore, the development of intelligent ESD simulators equipped with AI capabilities holds the promise of more predictive and proactive ESD testing in the future.

Conclusion

ESD simulators play an invaluable role in ensuring the reliability and robustness of electronic devices in the face of potential ESD events. By replicating these events in a controlled environment, they provide insights into the vulnerabilities of devices, paving the way for enhanced design and improved ESD protection. As we continue to advance technologically, these tools will be vital in guiding the development of resilient electronics that can withstand the electrostatic challenges of the modern world. Ensuring the right selection and proper use of these simulators will remain a key aspect in the lifecycle of any electronic product.