Explore the importance, functioning, and advancements of dielectric loss testers in maintaining electrical system reliability and safety.

Understanding Dielectric Loss Testers

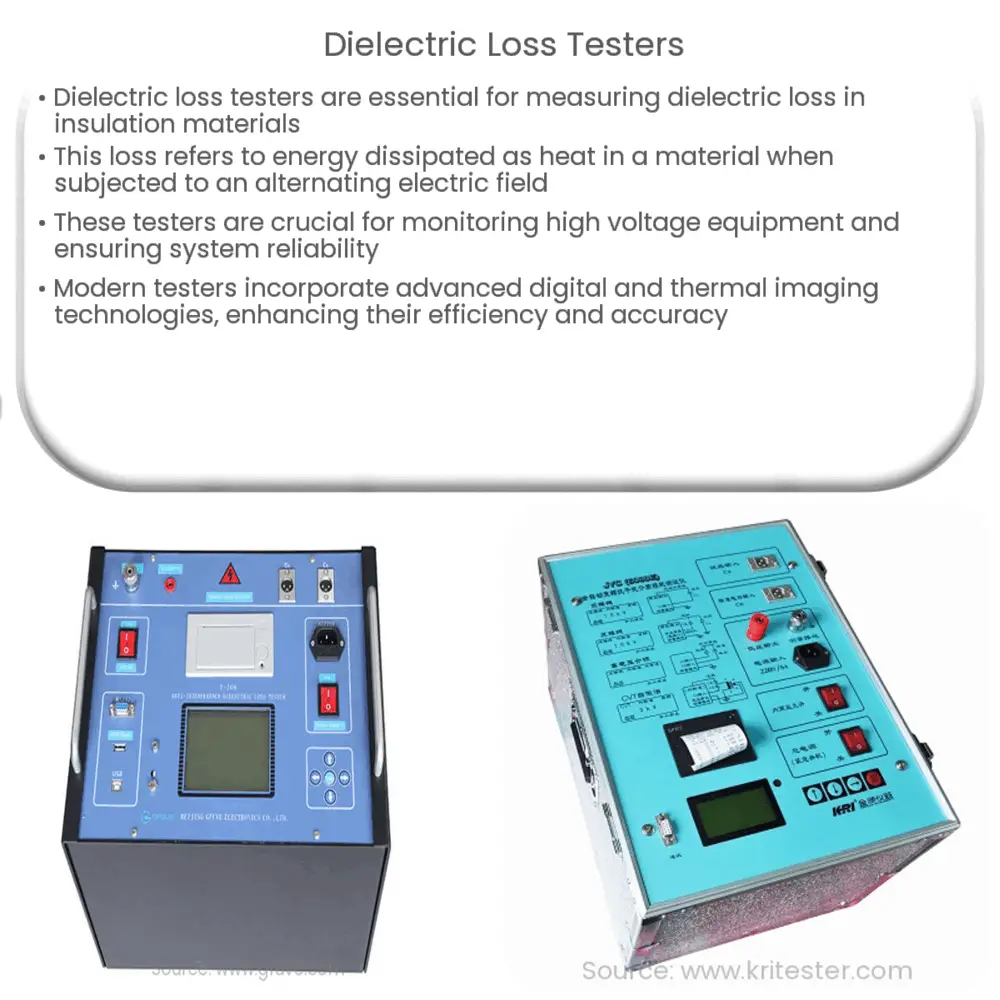

Dielectric loss testers, integral to the electrical industry, are sophisticated instruments designed for the precise measurement of dielectric loss in insulation materials. Understanding these devices necessitates delving into the fundamentals of dielectric loss and its importance in electrical systems.

The Concept of Dielectric Loss

Dielectric loss refers to the energy dissipated as heat in a dielectric material when it is subjected to an alternating electric field. This phenomenon is a consequence of the lag between the electric field and the polarisation of the material, which ultimately generates heat. The amount of heat produced is representative of the quality of the insulator, making this a crucial parameter to monitor in high voltage systems.

Functioning of Dielectric Loss Testers

Dielectric loss testers serve the primary purpose of measuring the dielectric dissipation factor (or loss tangent). These devices operate by applying an alternating voltage to the material under test, and then they accurately measure the resultant current. By analyzing the phase difference between the voltage and current, the tester calculates the dielectric loss or dissipation factor.

Importance of Dielectric Loss Testing

-

The primary use of dielectric loss testers is in the condition monitoring of high voltage equipment such as transformers, circuit breakers, and cables. By identifying potential insulation failures before they happen, operators can prevent costly breakdowns and improve system reliability.

-

These testers are also used in the material sciences field, where researchers use them to evaluate and improve dielectric materials’ properties. By understanding the dielectric loss characteristics, it’s possible to design materials with optimal performance for various applications.

-

Another area where dielectric loss testers are extensively used is in quality control. Manufacturers use these devices to ensure that the insulation materials used in their products meet the necessary performance and safety standards.

In conclusion, the role of dielectric loss testers cannot be understated in any sector that relies on high voltage electrical equipment. From enhancing system reliability to ensuring quality control, these devices contribute significantly to electrical safety and efficiency.

Components of Dielectric Loss Testers

While the design specifics of dielectric loss testers can vary, most include a high-frequency source to generate the alternating electric field, a voltage meter to measure the applied voltage, a current meter to measure the induced current, and a phase meter to determine the phase difference between the voltage and current. The readings from these components are then processed to calculate the dielectric loss or dissipation factor.

Latest Developments in Dielectric Loss Testing

-

With the advent of digital technology, modern dielectric loss testers are equipped with microprocessors that provide enhanced accuracy and efficiency. They are also capable of automatically calculating and displaying test results, which reduces the possibility of human error.

-

Another advancement is the incorporation of thermal imaging technology in dielectric loss testers. This feature enables the testers to visually identify hotspots in the insulation, which can provide early warning signs of potential insulation failure.

-

More recent advancements include the development of portable dielectric loss testers. These devices offer the same functionality as their larger counterparts but in a compact, easy-to-transport package. This development has significantly enhanced the versatility and applicability of these testers.

Conclusion

In summary, dielectric loss testers are crucial tools in the electrical industry and material sciences, offering invaluable insights into the health and quality of insulation materials. These devices have evolved significantly over the years, with modern testers incorporating advanced digital and thermal imaging technologies to enhance their accuracy and efficiency. As the need for high-voltage equipment continues to grow across various industries, so will the demand for dielectric loss testers. They represent a pivotal instrument in maintaining electrical safety, system reliability, and material integrity, underscoring their essential role in our technologically driven world.