Explore the critical role of insulation materials in electric motors, understand the different types, and learn about recent advancements in this field.

Understanding Motor Insulation Materials

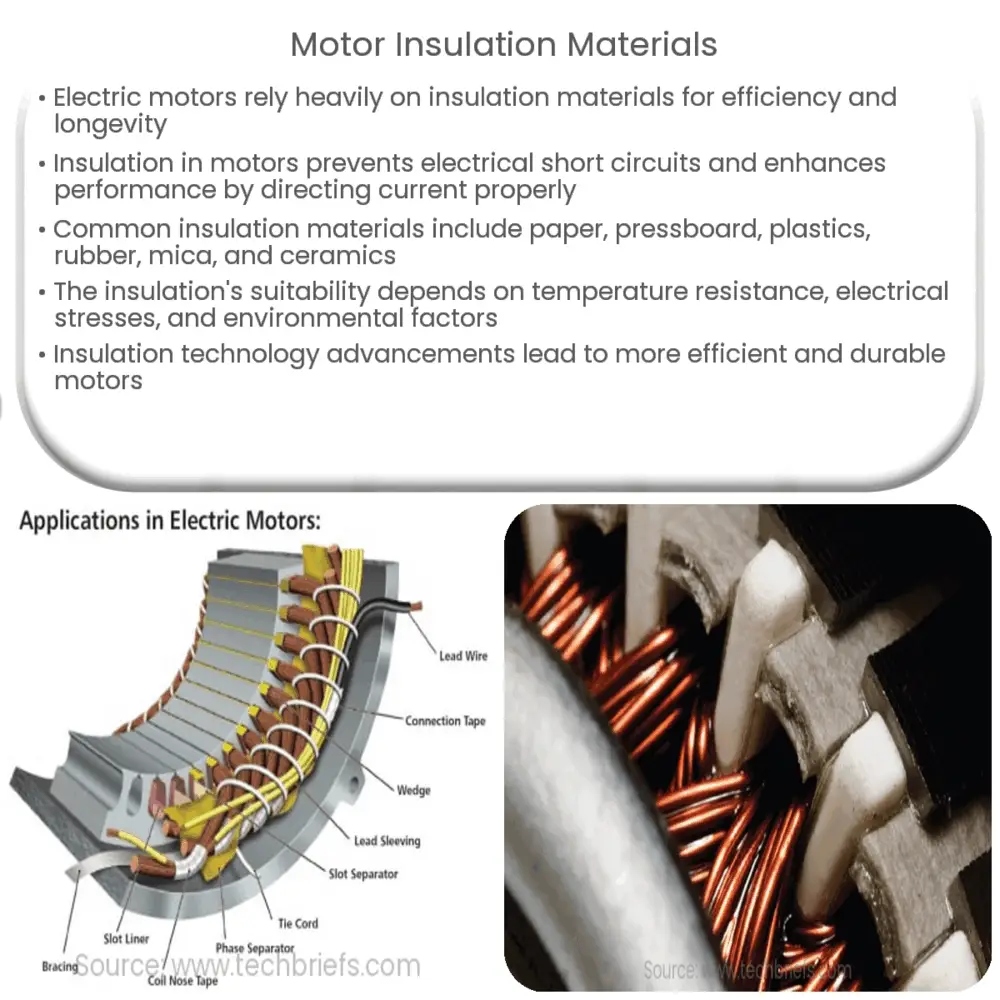

Electric motors are integral to a vast array of technologies and industries, from the simplest household appliances to complex industrial machinery. The efficiency and longevity of these motors significantly depend on the insulation materials used in their construction. Insulation is essential to isolate the current within the motor windings, prevent electrical faults, and support the mechanical structure of the motor.

The Necessity of Insulation

Insulation in motors serves to create a barrier between the conductive components and the stator, rotor, and housing. This barrier prevents electrical short circuits and mitigates the risk of equipment damage and user injury. By limiting the flow of electrical current to its intended path, insulation enhances the efficiency and performance of the motor. The insulation must withstand various stresses, including electrical, thermal, mechanical, and environmental, which underscores the importance of choosing the right insulation material.

Types of Motor Insulation Materials

- Paper and Pressboard: These materials have been traditionally used for insulation in motors, especially in the form of cellulose paper or pressboard. They are cost-effective and provide decent thermal resistance. However, they are susceptible to moisture and have limited mechanical strength.

- Plastics and Rubber: Synthetic materials like PVC (Polyvinyl Chloride), PE (Polyethylene), and rubber are widely used due to their higher insulation capabilities and improved mechanical strength. However, they tend to deteriorate under high temperature.

- Mica: Mica is a mineral that exhibits superior electrical insulation properties, high-temperature resistance, and excellent mechanical strength. It is often used in conjunction with other materials such as glass, resins, and ceramics to enhance its performance.

- Ceramics and Glass: These materials offer high-temperature resistance and good insulation properties but lack mechanical flexibility. They are typically used in motors that operate under extreme temperature conditions.

Insulation Classes

In addition to material type, the insulation system is classified according to its maximum allowable operating temperature. These categories, referred to as insulation classes, are defined by the International Electrotechnical Commission (IEC). They are Class A (105°C), Class E (120°C), Class B (130°C), Class F (155°C), Class H (180°C), and Class C (over 180°C).

The selection of the insulation class depends on the application’s specific requirements, the expected motor load, and the environmental conditions under which the motor will operate. This classification system helps engineers and designers choose the most suitable insulation material for a given application, balancing performance, longevity, and cost.

Advancements in Motor Insulation

With the advent of new technologies and materials, the landscape of motor insulation is continually evolving. Developments in composite materials and synthetic resins are enhancing the performance and lifespan of motor insulation. For instance, high-performance epoxy resins combined with mica or glass are used to create insulation systems capable of withstanding extreme temperatures and harsh operating conditions. These advancements contribute to more energy-efficient and durable motors.

Considerations for Choosing Insulation Materials

The selection of insulation material should be guided by the specific requirements of the motor’s application. The material should be capable of withstanding the maximum operating temperature and resisting the electrical stresses the motor will encounter. Other considerations include the insulation’s mechanical strength, resistance to environmental factors such as moisture and chemicals, and cost-effectiveness.

Moreover, the motor’s design should allow for adequate cooling to prevent overheating of the insulation material. The ability of the insulation system to dissipate heat effectively is crucial in maintaining the motor’s overall performance and longevity. Regular maintenance and testing of the insulation system can also help to ensure its continued functionality and detect potential issues before they lead to motor failure.

Conclusion

In conclusion, the insulation system is a critical aspect of electric motor design. It ensures electrical isolation, prevents short-circuits, and contributes to the motor’s overall performance and longevity. Various materials, each with its unique properties and considerations, can be used for motor insulation. The choice of material depends on the application’s specific requirements, including operating temperature, electrical stresses, and environmental conditions.

With advancements in technology and materials, motor insulation continues to improve, enabling the creation of more energy-efficient and durable motors. Through careful selection, adequate cooling, and regular maintenance, the insulation system can ensure the reliable operation of electric motors, contributing to the seamless functioning of many of our everyday technologies and industrial systems.