Column load cells are versatile force sensors that convert mechanical strain into electrical signals for precise weight and force measurements.

Understanding Column Load Cells: Functionality and Applications

Introduction

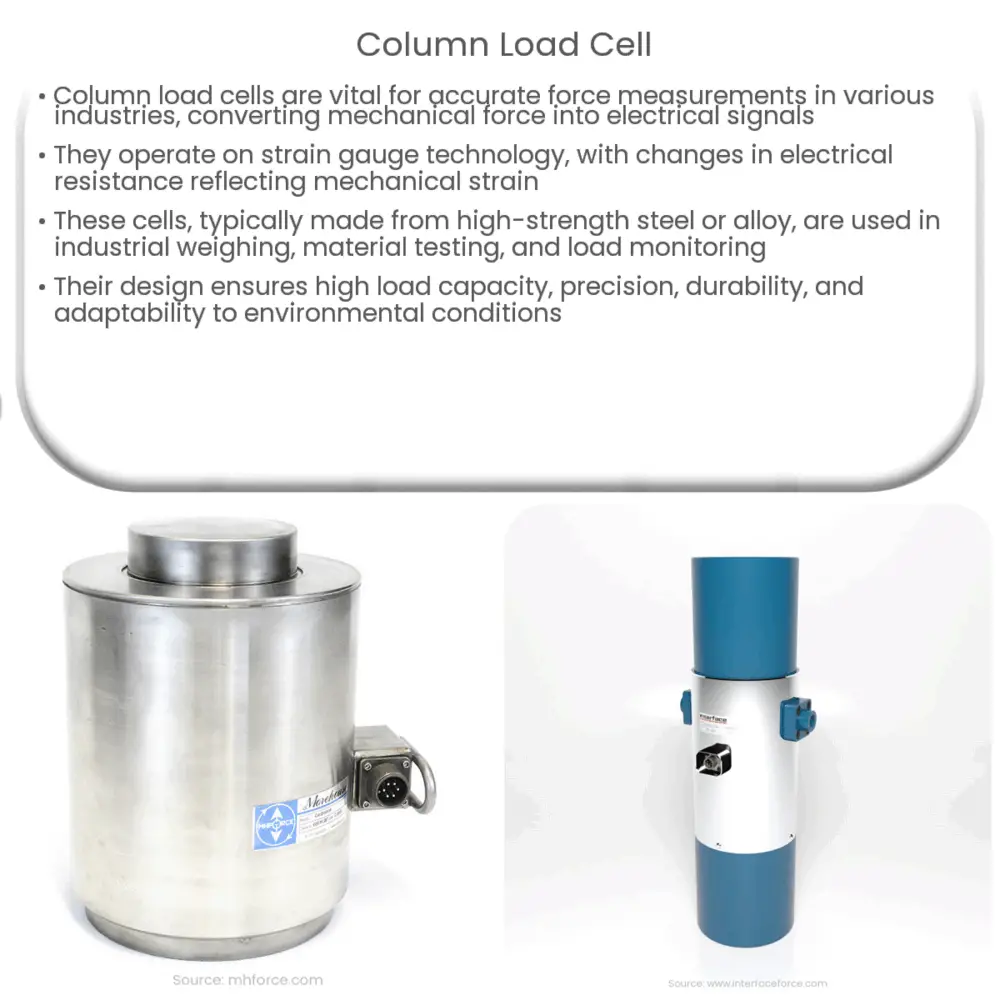

Column load cells are essential components in various industries, providing accurate and reliable force measurement solutions for a wide range of applications. These devices convert mechanical force into electrical signals, making it possible to measure weight, tension, and compression with ease. In this article, we will explore the principles behind column load cells, their design, and their common applications.

Working Principle of Column Load Cells

Column load cells are based on the principle of strain gauge technology, where a change in electrical resistance is proportional to the mechanical strain experienced by a material. These load cells consist of a central column made of high-strength steel or alloy, which is designed to deform elastically under a force. The strain gauges are mounted on the column, and as the column deforms under load, the strain gauges experience a change in resistance. This change in resistance is then converted into an electrical signal, which can be measured and calibrated to represent the applied force.

Design and Construction

There are several factors to consider when designing a column load cell, such as material selection, column dimensions, and strain gauge placement. The choice of materials is crucial, as it directly affects the load cell’s performance, durability, and sensitivity. High-strength steel or alloy materials, such as stainless steel, are commonly used for their excellent mechanical properties and corrosion resistance.

The column dimensions, including its height and diameter, are determined by the required load capacity and the desired sensitivity. A taller column will generally provide a higher sensitivity, while a larger diameter will offer increased load capacity. The strain gauges are typically installed on the column’s side or within a cavity, and their placement is carefully optimized to ensure accurate force measurement and minimal interference from external factors, such as temperature and humidity.

Common Applications of Column Load Cells

Column load cells find applications in various industries due to their versatility, accuracy, and durability. Some of the most common applications include:

- Industrial Weighing: Column load cells are widely used in industrial weighing systems, such as silos, hoppers, and tanks, where high-capacity and accurate weight measurement is crucial for inventory control and process optimization.

- Material Testing: In material testing applications, column load cells are used to measure the force required to compress, stretch, or bend a sample, providing valuable data on material properties and performance under different conditions.

- Load Monitoring: Column load cells are employed in various load monitoring applications, such as crane safety systems and structural health monitoring, to ensure safety and prevent overloading or structural failure.

Advantages of Column Load Cells

Column load cells offer several advantages over other types of load cells, making them an attractive choice for many applications:

- High Load Capacity: Due to their robust design, column load cells can handle very high loads, often ranging from a few thousand pounds to several hundred thousand pounds. This makes them suitable for applications that require measuring large forces or weights.

- Accuracy and Stability: Column load cells provide excellent accuracy and long-term stability, ensuring consistent and reliable force measurements throughout their lifespan.

- Environmental Resistance: The materials used in column load cells, such as stainless steel, offer excellent corrosion resistance and durability in harsh environments, making them suitable for outdoor and industrial applications.

- Compact Design: Column load cells are designed to be compact, allowing for easy integration into existing systems or tight spaces where other load cell types may not fit.

Selecting the Right Column Load Cell

When choosing a column load cell for a specific application, there are several factors to consider:

- Load Capacity: Select a load cell with a capacity that matches or exceeds the maximum force or weight expected in the application.

- Accuracy Requirements: Determine the accuracy requirements of the application and choose a load cell with a suitable accuracy rating, usually expressed as a percentage of the rated capacity.

- Environmental Conditions: Consider the operating temperature, humidity, and potential exposure to corrosive substances when selecting a load cell. Opt for a model with appropriate environmental protection, such as a stainless steel or hermetically sealed column load cell, if necessary.

- Mounting Configuration: Ensure that the selected load cell can be easily integrated into the existing system or structure, taking into account factors such as space constraints and mounting requirements.

Conclusion

Column load cells play a crucial role in a wide range of industries, providing accurate and reliable force measurement solutions. With their robust design, high load capacity, and excellent environmental resistance, these devices are well-suited for applications such as industrial weighing, material testing, and load monitoring. By carefully considering factors like load capacity, accuracy requirements, and environmental conditions, users can select the right column load cell for their specific needs and ensure reliable, long-lasting performance.