Explore the science and importance of volume resistivity meters, their applications across various industries, and tips for choosing one.

Understanding Volume Resistivity Meters

Volume resistivity meters are essential tools used across multiple industries to measure the resistivity of various materials. As a fundamental parameter of material science, resistivity is a measure of a substance’s ability to resist the flow of electrical current. The volume resistivity is a specific type of resistivity that considers the total volume of a material.

The Science Behind Volume Resistivity

At its core, resistivity relies on the principle of Ohm’s law, which states that the current through a conductor between two points is directly proportional to the voltage across the two points, and inversely proportional to the resistance between them. The equation is often expressed as I = V/R, where I is current, V is voltage, and R is resistance.

When measuring volume resistivity, we use a unit known as ohm-meters (Ω⋅m). In simple terms, volume resistivity is calculated by multiplying the resistance of the material by the cross-sectional area, and then dividing by the length of the material.

Why is Volume Resistivity Important?

Understanding the resistivity of a material, especially its volume resistivity, has significant implications in various industries. For instance, in the electronics industry, manufacturers need to know the resistivity of a semiconductor to ensure its suitability for a specific application. Similarly, in the construction industry, the resistivity of materials like concrete can indicate their durability and structural integrity.

How Do Volume Resistivity Meters Work?

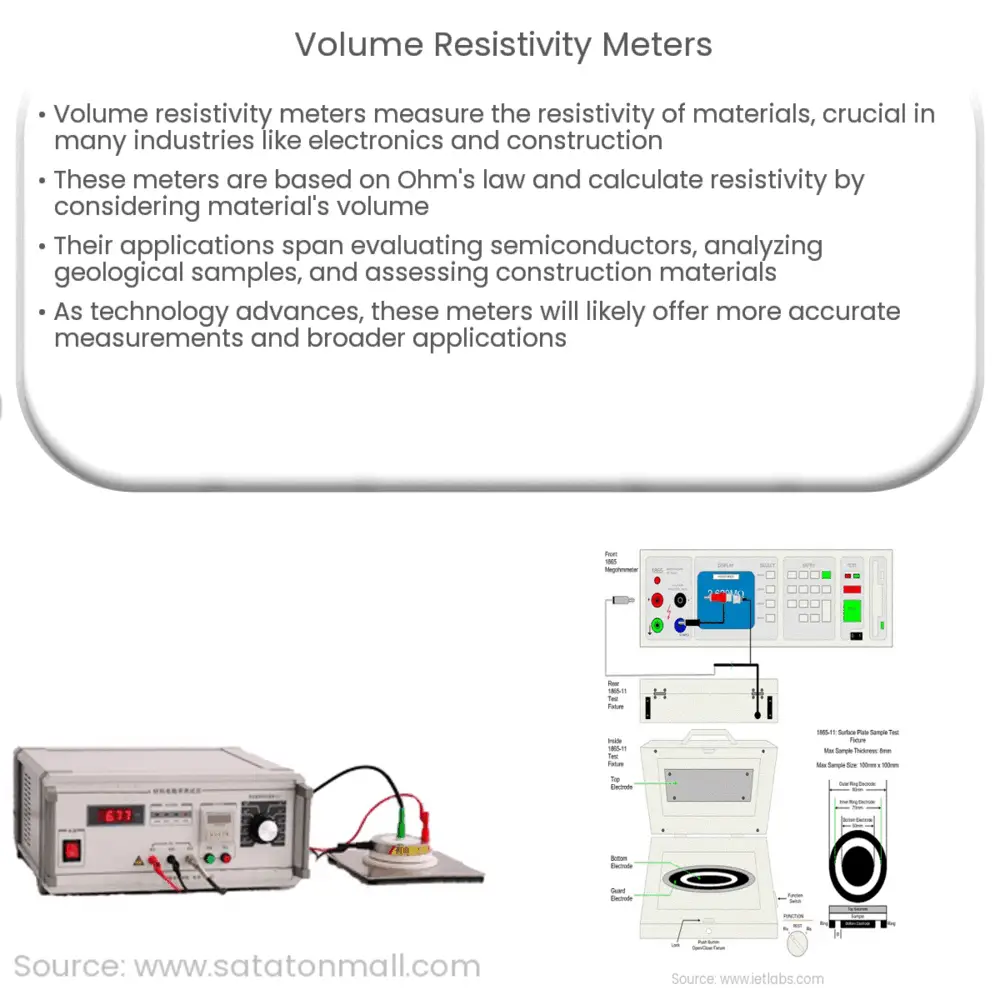

Volume resistivity meters employ a simple but effective methodology to measure the resistivity of materials. They generally use a four-point probe or a two-point probe method. The four-point probe method is commonly used for more accurate measurements as it reduces the effect of contact resistance. In this method, a constant current is sent through the outer probes, and the potential difference or voltage drop is measured across the inner probes. The calculated resistance is then used to determine the volume resistivity of the material under test.

Despite the complexity of the concept, modern volume resistivity meters are designed to be user-friendly, often featuring digital displays, data storage capabilities, and even connectivity options for data transfer and analysis.

Applications of Volume Resistivity Meters

Volume resistivity meters have found applications in various industries due to their capability to assess the resistivity of materials. In the electronics industry, these meters are utilized in the evaluation of semiconductors and insulators, which are fundamental to designing and manufacturing electrical components and devices.

In the geological and environmental science fields, volume resistivity meters are used to analyze soil and rock samples. Such assessments aid in the understanding of geological formations, and also play a crucial role in environmental assessments, groundwater studies, and even archaeological research.

The construction industry also leverages these tools to assess the quality of materials like concrete and steel. By understanding the volume resistivity, engineers can make informed decisions about the durability and reliability of their construction materials, thereby ensuring the safety and longevity of the structures they build.

Choosing a Volume Resistivity Meter

When selecting a volume resistivity meter, several factors should be considered. First, the accuracy of the device is paramount – it should provide precise readings, regardless of the material being tested. Second, consider the range of resistivity the device can measure – different materials have vastly different resistivities, so a versatile meter is often the most beneficial. Lastly, think about the usability of the device – a meter with an intuitive interface, digital display, and data transfer capabilities can make the process of measuring resistivity much easier and efficient.

Conclusion

In summary, volume resistivity meters are an indispensable tool across various industries, playing a critical role in material science, electronics, construction, and environmental studies. By understanding and measuring the resistivity of materials, these devices provide valuable insights that inform the manufacturing process, enhance product performance, and promote safety and sustainability. The sophistication and utility of these devices underscore their importance in our increasingly technologically-oriented society. As technology continues to advance, it’s likely that volume resistivity meters will also evolve, delivering even more accurate measurements and diverse applications.