Vibrating Beam Accelerometers are precise devices that measure acceleration using resonance frequency shifts, ideal for aerospace, automotive, and consumer electronics.

Vibrating Beam Accelerometer: Principles and Applications

Introduction

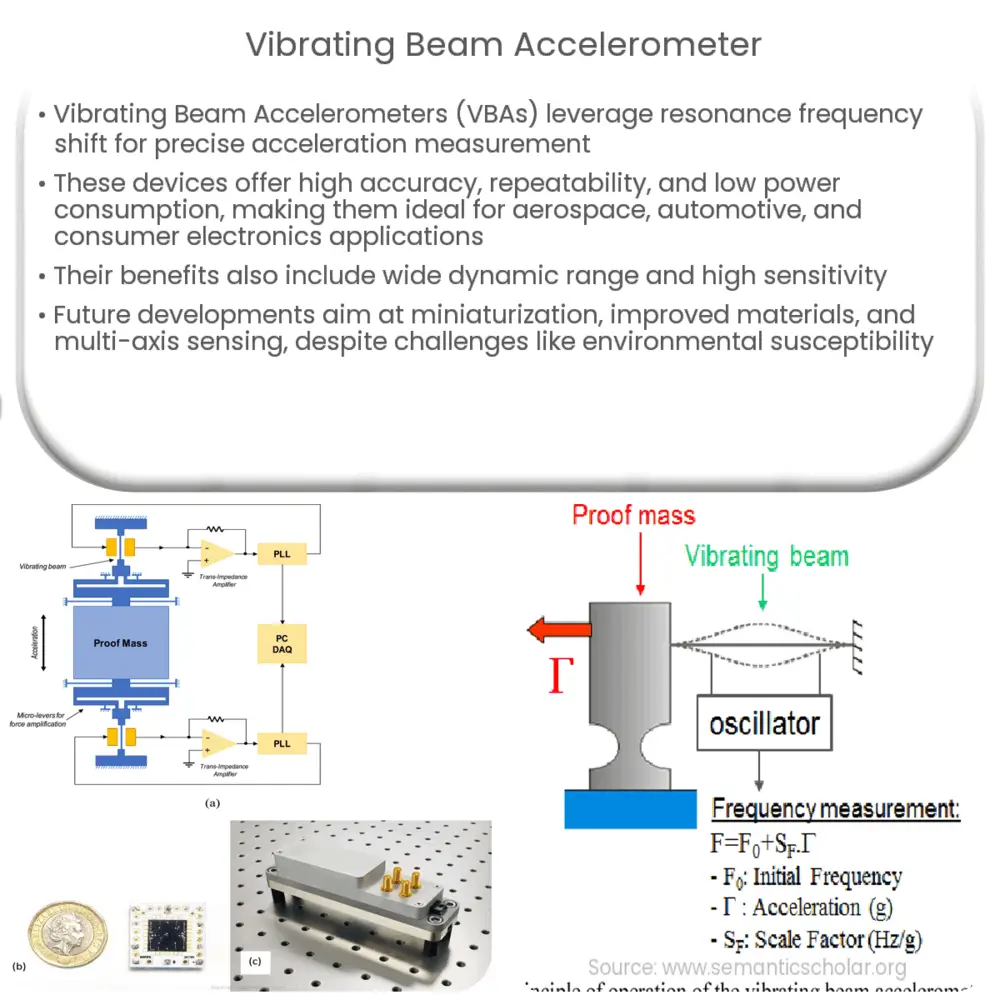

The Vibrating Beam Accelerometer (VBA) is a highly sensitive and precise device used for measuring acceleration. It operates on the principle of resonance frequency shift, which is directly proportional to the applied force. The VBA has found numerous applications in various industries, such as aerospace, automotive, and consumer electronics, owing to its high accuracy, repeatability, and low power consumption. This article aims to provide a comprehensive overview of the principles, advantages, and applications of VBAs.

Working Principle

The fundamental principle behind the VBA is the Coriolis effect, which is an inertial force experienced by an object moving in a rotating frame of reference. When the accelerometer experiences acceleration, a resonating beam inside the device is set in motion. The Coriolis force acts on the vibrating beam, causing a shift in its resonance frequency. This frequency shift is directly proportional to the applied acceleration and can be measured to determine the acceleration magnitude.

The VBA typically consists of a vibrating beam, made of a piezoelectric material such as quartz or silicon, fixed at both ends. The beam is driven into oscillation by an external force or an internal electrostatic force. As the accelerometer experiences acceleration, the Coriolis effect generates a force perpendicular to the beam’s motion, causing the resonance frequency to shift. This shift is detected by a set of capacitive or piezoresistive sensors, which are then used to compute the acceleration value.

Advantages of Vibrating Beam Accelerometers

Vibrating Beam Accelerometers offer several advantages over other types of accelerometers, such as capacitive, piezoresistive, and MEMS-based accelerometers. Some of the key benefits include:

- High Sensitivity and Accuracy: Due to the precise frequency measurements and low noise levels, VBAs can detect even minute changes in acceleration, providing high accuracy and sensitivity.

- Repeatability: The stable resonance frequency of the beam ensures excellent repeatability and long-term stability, making VBAs ideal for applications that require consistent measurements over extended periods.

- Low Power Consumption: The VBA’s inherent low power consumption makes it suitable for battery-powered devices and remote sensing applications.

- Wide Dynamic Range: VBAs can measure a broad range of acceleration levels, from low-frequency vibrations to high-frequency shocks, making them versatile for various applications.

Applications of Vibrating Beam Accelerometers

Due to their high sensitivity, accuracy, and versatility, Vibrating Beam Accelerometers have found applications across a wide range of industries. Some of the most common use cases include:

- Aerospace: VBAs are used in various aerospace applications, such as inertial navigation systems, guidance systems, and vibration monitoring in aircraft and satellites. Their high accuracy and low power consumption make them ideal for these critical applications.

- Automotive: In the automotive industry, VBAs are utilized for vehicle stability control, suspension systems, and crash testing. They help enhance vehicle safety and performance by providing precise measurements of acceleration and vibration.

- Consumer Electronics: VBAs are used in smartphones, tablets, and wearables for motion sensing, gesture recognition, and activity tracking. Their low power consumption and high sensitivity make them suitable for these battery-operated devices.

- Structural Health Monitoring: VBAs are employed in monitoring the health and integrity of structures such as bridges, buildings, and pipelines. They can detect small changes in vibration patterns, indicating potential structural issues or damages.

- Seismic Measurements: Due to their high sensitivity to low-frequency vibrations, VBAs are used in seismology for detecting and measuring ground motion during earthquakes and other seismic events.

Future Developments and Challenges

As the demand for more accurate and sensitive accelerometers increases, researchers and manufacturers are continually working on improving the performance of Vibrating Beam Accelerometers. Some of the areas of ongoing research and development include:

- Miniaturization: The development of smaller and lighter VBAs will enable their integration into more compact devices and systems, without compromising on performance.

- Improved Materials: The use of advanced materials with better mechanical and piezoelectric properties can lead to higher sensitivity and accuracy in VBAs.

- Multi-axis Sensing: The development of multi-axis VBAs will allow for simultaneous measurement of acceleration in multiple directions, further expanding their applicability.

Despite their numerous advantages, Vibrating Beam Accelerometers still face some challenges. One of the primary challenges is their susceptibility to environmental factors, such as temperature and humidity, which can affect the resonance frequency and sensor performance. Further research and development in this area can help mitigate these challenges and enhance the performance and reliability of VBAs.

Conclusion

Vibrating Beam Accelerometers have emerged as a leading technology for accurate and sensitive acceleration measurement in various industries. With ongoing research and development, VBAs are poised to continue advancing and expanding their applications, making them an indispensable tool in modern sensing and motion detection systems.