A mechanical accelerometer measures acceleration using a mass-spring-damper system, with applications in aerospace, automotive, and consumer electronics.

Mechanical Accelerometer: An Overview

Introduction

The mechanical accelerometer is a device used for measuring acceleration, which is a change in velocity over time. By measuring acceleration, these devices can help determine the position, velocity, and orientation of objects in motion. Mechanical accelerometers have a wide range of applications in various industries, including aerospace, automotive, and consumer electronics. In this article, we will explore the basic principles of mechanical accelerometers, their history, and their applications in today’s world.

Principles of Mechanical Accelerometers

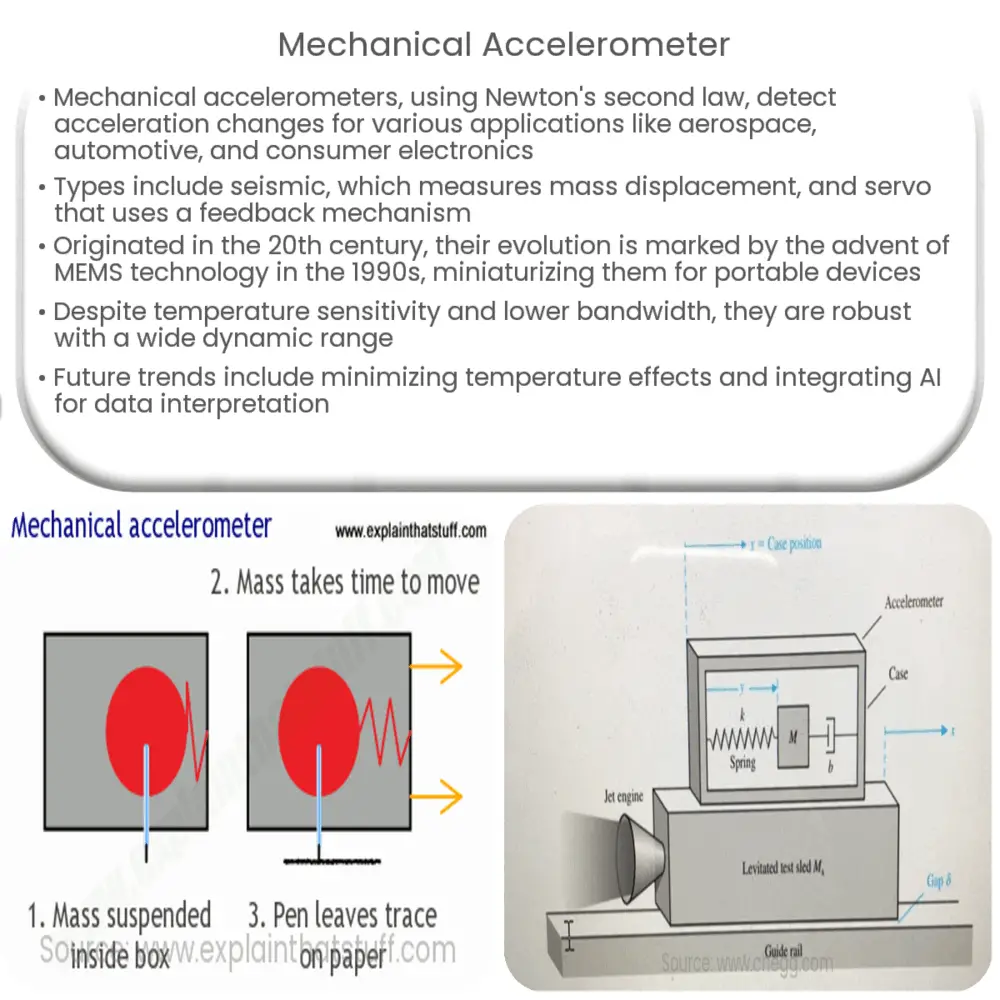

Mechanical accelerometers function based on Newton’s second law of motion, which states that the force acting on an object is equal to the product of its mass and acceleration. These devices utilize a mass-spring-damper system to detect changes in acceleration. When the accelerometer experiences acceleration, the inertial mass within the device moves in response to the applied force. This movement causes a change in the position of the mass relative to the spring and damper elements, which can then be translated into an acceleration measurement.

There are two primary types of mechanical accelerometers: seismic and servo. Seismic accelerometers, also known as inertial accelerometers, rely on the displacement of a mass caused by the acceleration force. This displacement is then measured by a transducer, such as a capacitive or piezoelectric sensor, which converts the mechanical motion into an electrical signal. Servo accelerometers, on the other hand, use a feedback mechanism to maintain a constant force on the mass, counteracting the acceleration. The amount of force required to maintain this balance is proportional to the acceleration and can be measured to determine the acceleration experienced by the device.

History of Mechanical Accelerometers

The concept of mechanical accelerometers dates back to the early 20th century, with the first devices being developed for use in aircraft and rockets. These early accelerometers used a variety of mechanical designs, including pendulum-based systems and rotating mass gyroscopes. The development of solid-state accelerometers in the latter half of the 20th century led to a significant reduction in size and weight of these devices, making them more practical for a wider range of applications.

In the 1990s, the advent of microelectromechanical systems (MEMS) technology revolutionized the accelerometer market. MEMS accelerometers are miniature devices that integrate mechanical structures, such as springs and masses, with electronic components on a single silicon chip. This integration allows for the fabrication of highly sensitive and compact accelerometers with low power consumption, making them ideal for use in portable electronic devices.

Applications of Mechanical Accelerometers

Mechanical accelerometers have a diverse range of applications across various industries. In the aerospace industry, they are used for navigation, guidance, and control systems in aircraft and spacecraft. In the automotive sector, accelerometers play a crucial role in safety systems, such as airbag deployment and electronic stability control. They are also commonly found in consumer electronics, enabling features such as tilt sensing, gesture recognition, and activity tracking in smartphones, tablets, and wearable devices.

Advantages and Limitations of Mechanical Accelerometers

Mechanical accelerometers offer several advantages over other types of accelerometers. Their simple design and construction make them robust and reliable, with a high tolerance for shock and vibration. This makes them particularly suitable for use in harsh environments and high-stress applications, such as aerospace and industrial settings. Additionally, mechanical accelerometers typically have a wide dynamic range, which allows them to accurately measure both small and large accelerations.

However, mechanical accelerometers also have some limitations. They can be sensitive to temperature changes, which can affect the performance of the spring and damper elements. This sensitivity can lead to measurement errors if not properly compensated for. Mechanical accelerometers may also have a lower bandwidth compared to other accelerometer types, such as MEMS or optical accelerometers, which can limit their ability to measure high-frequency vibrations.

Recent Developments and Future Trends

As technology continues to advance, mechanical accelerometers are evolving to meet the demands of modern applications. One area of focus is the development of materials and designs to reduce the effects of temperature variations on the performance of these devices. Researchers are also exploring new fabrication techniques and materials to further miniaturize mechanical accelerometers, making them even more suitable for integration into compact electronic devices.

Another trend is the integration of mechanical accelerometers with other sensors, such as gyroscopes and magnetometers, to create inertial measurement units (IMUs). These multi-sensor devices can provide more accurate and comprehensive motion data, enabling improved performance in applications such as robotics, virtual reality, and autonomous vehicles.

Looking forward, it is expected that advances in artificial intelligence and machine learning will play an increasing role in the processing and interpretation of accelerometer data. This could lead to the development of smarter, more adaptive systems that can more accurately and efficiently utilize the information provided by mechanical accelerometers.

Conclusion

Mechanical accelerometers have come a long way since their inception in the early 20th century. Today, they are integral components in a wide range of applications across various industries, including aerospace, automotive, and consumer electronics. As technology continues to advance, these devices are expected to become even more sophisticated and versatile, enabling new possibilities in motion sensing and control. By understanding the principles, history, and applications of mechanical accelerometers, we can better appreciate the impact these devices have on our daily lives and anticipate their future potential.