A three-phase diode bridge rectifier converts three-phase AC power into DC, offering high efficiency, reduced ripple, and improved load sharing in various applications.

Understanding the Three-Phase Diode Bridge Rectifier

Introduction

A three-phase diode bridge rectifier is an essential component in the world of electrical engineering, designed to convert three-phase alternating current (AC) into direct current (DC). It is widely used in power supply systems, motor drives, and various other applications due to its efficient and reliable performance. In this article, we will delve into the fundamentals of three-phase diode bridge rectifiers, their advantages, and typical applications.

Basics of the Three-Phase Diode Bridge Rectifier

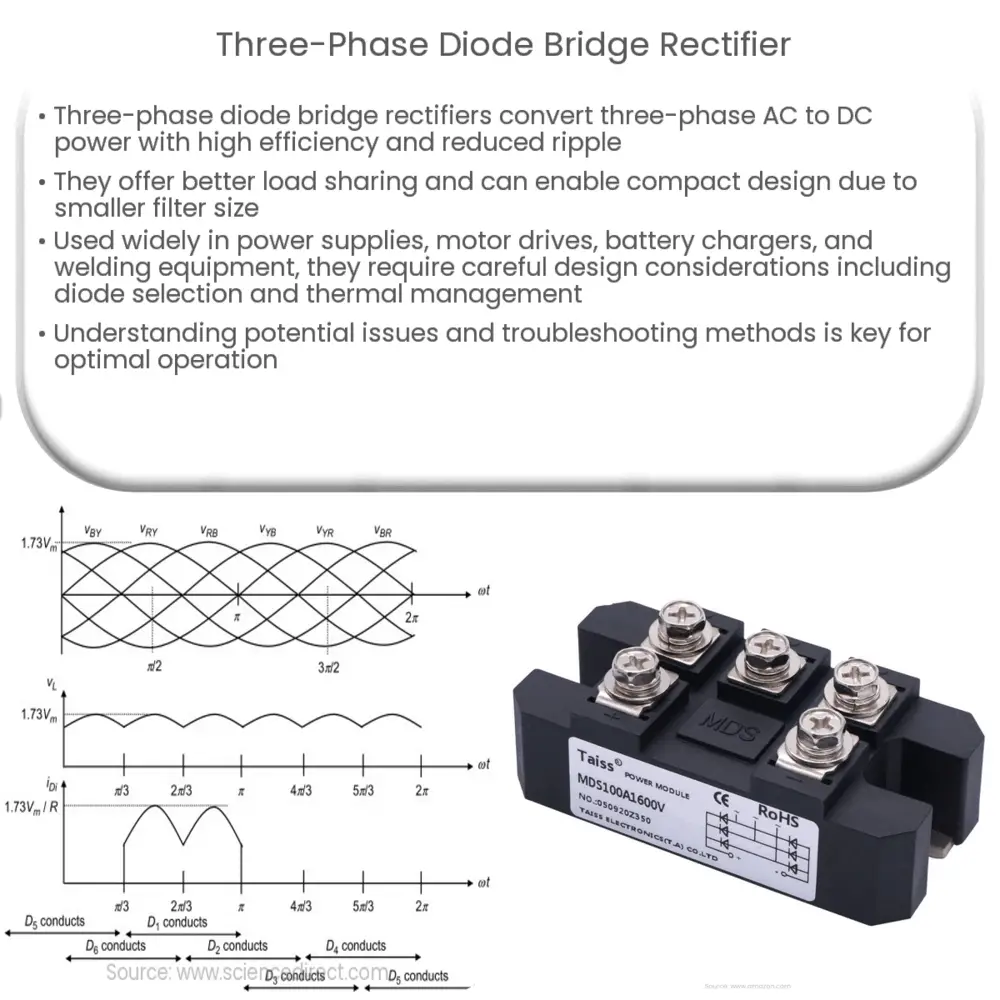

A three-phase diode bridge rectifier consists of six diodes connected in a bridge configuration, with each diode conducting current for 120 degrees of the input waveform. The input to the rectifier is a three-phase AC supply, which is typically generated by a three-phase generator or transformer. The output is a pulsating DC waveform that can be further processed or utilized in various applications.

The three-phase diode bridge rectifier operates by only allowing the positive half-cycles of the input AC waveform to pass through, effectively “clipping” the negative half-cycles. This is achieved by the diodes, which only conduct current in one direction, blocking the negative half-cycles. The result is a series of positive half-cycles that form the pulsating DC output.

Advantages of Three-Phase Diode Bridge Rectifiers

Compared to their single-phase counterparts, three-phase diode bridge rectifiers offer several benefits:

- Higher Efficiency: Three-phase rectifiers have lower losses due to the continuous conduction of current. This results in a higher overall efficiency and reduced power dissipation.

- Reduced Output Ripple: The pulsating DC output of a three-phase rectifier has a lower ripple voltage compared to single-phase rectifiers. This means that the output voltage is smoother, which is advantageous for applications requiring a stable DC supply.

- Smaller Filter Size: Due to the reduced output ripple, the size of the output filter components can be smaller, which in turn leads to a more compact overall design.

- Better Load Sharing: In a three-phase rectifier, the current is more evenly distributed among the diodes, reducing the stress on each individual diode and improving the overall reliability of the rectifier.

Typical Applications of Three-Phase Diode Bridge Rectifiers

Three-phase diode bridge rectifiers are widely used in various industries and applications, including:

- Power Supplies: They are commonly found in industrial and commercial power supply systems, where they convert three-phase AC power into a stable DC voltage for use in various electrical devices and systems.

- Motor Drives: In motor drive applications, three-phase rectifiers are employed to provide the DC voltage required for the operation of DC motors or to supply power to an inverter for driving AC motors.

- Battery Chargers: They are used in battery charging systems, where the rectifier converts the AC input into a controlled DC output for charging batteries.

- Welding Equipment: In electric arc welding processes, three-phase rectifiers are used to supply the DC current necessary for the welding operation.

Design Considerations for Three-Phase Diode Bridge Rectifiers

When designing a three-phase diode bridge rectifier, there are several important factors to consider:

- Diode Selection: The diodes used in the rectifier must be capable of handling the maximum voltage and current requirements of the application. Important parameters to consider include the diode’s maximum forward current, reverse voltage, and power dissipation.

- Thermal Management: As diodes dissipate heat during operation, proper thermal management is crucial to ensure the rectifier’s reliability and longevity. This may involve using heat sinks, thermal paste, or forced air cooling to maintain the diode junction temperature within the acceptable range.

- Output Filtering: To further smooth the pulsating DC output and reduce ripple voltage, an output filter is often required. The design of this filter may involve using passive components like capacitors and inductors, or more complex active filter designs.

- Load Characteristics: It is important to consider the load’s characteristics when designing a three-phase rectifier, as this can impact the rectifier’s performance and efficiency. Factors to consider include the load’s voltage and current requirements, its duty cycle, and any specific requirements for output voltage stability.

Common Issues and Troubleshooting

Despite their advantages, three-phase diode bridge rectifiers can sometimes experience issues that require troubleshooting. Some common problems include:

- Diode Failure: Diode failure can occur due to excessive current, voltage, or temperature stresses. If a diode fails, it can result in a short circuit or an open circuit, depending on the failure mode. Troubleshooting this issue involves identifying and replacing the faulty diode.

- Excessive Output Ripple: If the output ripple voltage is higher than expected, this can indicate issues with the output filter or the rectifier’s design. Potential solutions include optimizing the output filter or adjusting the rectifier’s design parameters.

- Overheating: Overheating can occur if the rectifier’s thermal management is insufficient or if the diodes are subjected to excessive power dissipation. Troubleshooting this issue involves improving the thermal management system or identifying and addressing the root cause of the excessive power dissipation.

- Load Instability: In some cases, the load connected to the rectifier may exhibit instability or oscillations. This can be due to insufficient output voltage regulation or issues with the load itself. Troubleshooting this issue may involve adjusting the output voltage regulation or addressing any issues with the load.

Conclusion

Three-phase diode bridge rectifiers play a crucial role in the conversion of three-phase AC power to DC power, offering advantages such as higher efficiency, reduced output ripple, and better load sharing. They are employed in a wide range of applications, including power supplies, motor drives, battery chargers, and welding equipment. Proper design considerations, including diode selection, thermal management, output filtering, and load characteristics, ensure optimal performance and reliability. Familiarity with common issues and troubleshooting techniques is essential for addressing any challenges that may arise in the operation of three-phase diode bridge rectifiers.