Stranded wire is a flexible, durable electrical conductor composed of multiple thin strands, ideal for applications requiring frequent movement.

Understanding Stranded Wire: An In-Depth Look

Introduction to Stranded Wire

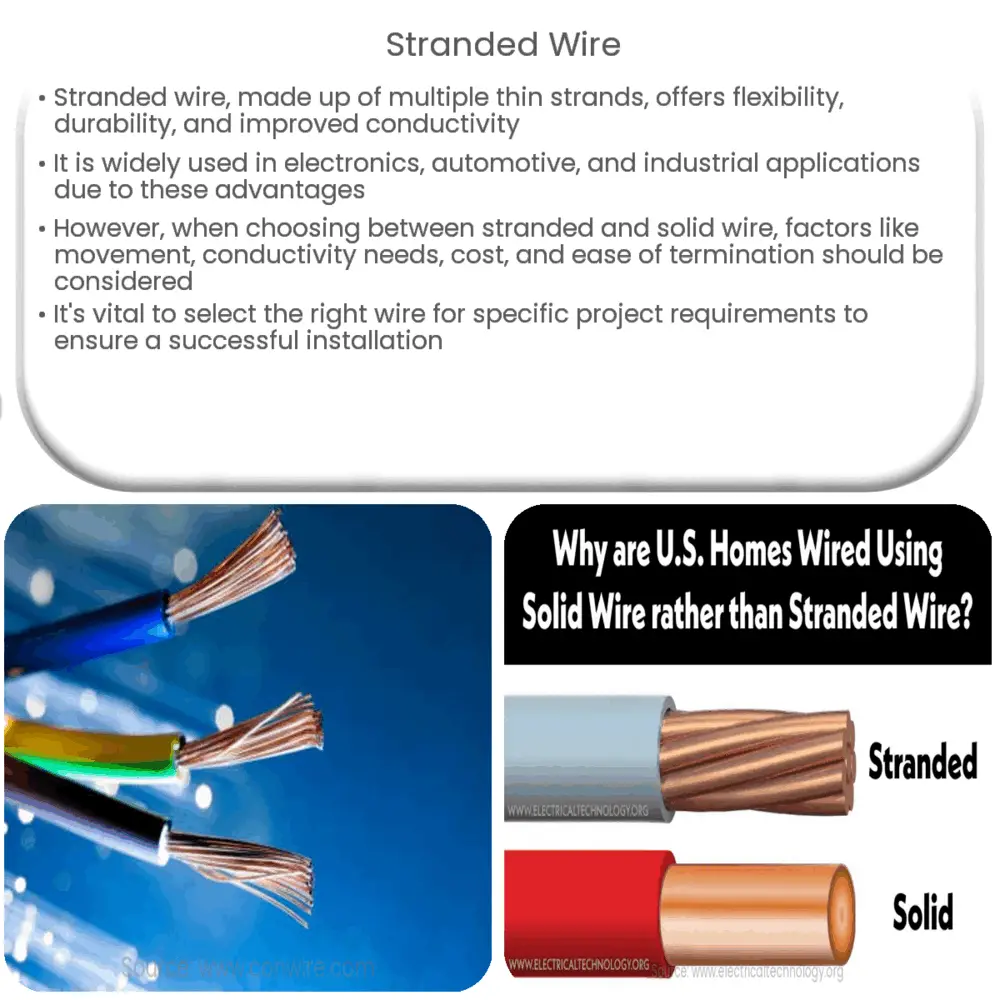

Stranded wire, a common type of electrical wire, is widely used in various applications due to its versatility, flexibility, and durability. It consists of multiple strands of thin wire bundled together, which enhances its ability to bend and flex without breaking. This article will delve into the composition, benefits, and applications of stranded wire, as well as its comparison to solid wire.

Composition of Stranded Wire

Stranded wire is made up of numerous thin strands of conductive metal, typically copper or aluminum, that are twisted or braided together to form a single conductor. These strands can vary in number and diameter, depending on the specific requirements of the application. The strands are often coated with a thin layer of insulation to prevent electrical shorts and facilitate flexibility. A protective outer sheath, usually made of thermoplastic or thermoset materials, encases the stranded conductor, providing additional insulation and protection from environmental factors.

Benefits of Stranded Wire

Stranded wire offers several advantages over its solid wire counterpart. These benefits include:

- Flexibility: Due to its multi-strand construction, stranded wire is more flexible than solid wire, making it ideal for applications where the wire is subjected to frequent movement or bending. This increased flexibility also allows for tighter bends, reducing the space required for wiring installations.

- Durability: The multiple strands in stranded wire distribute stress across the entire conductor, rather than concentrating it on a single point. This feature increases the wire’s resistance to metal fatigue and breakage caused by repeated bending or flexing.

- Increased conductivity: The larger surface area provided by the multiple strands of wire results in lower resistance and improved electrical conductivity, making stranded wire a more efficient choice for some applications.

Applications of Stranded Wire

Stranded wire is commonly used in various industries and applications due to its flexibility and durability. Some of these applications include:

- Electronics: Stranded wire is ideal for connecting components within electronic devices, such as computers, televisions, and audio equipment, where the wire may be subject to movement or bending.

- Automotive: In vehicles, stranded wire is used for wiring harnesses and connections that require flexibility and resistance to vibration, such as engine components and lighting systems.

- Industrial: Stranded wire is often used in robotics, automation, and control systems, where its flexibility allows for easy routing and installation in tight spaces.

While stranded wire offers several advantages, it is essential to consider the specific requirements of each application before selecting the appropriate type of wire. In the second part of this article, we will explore the differences between stranded and solid wire and provide guidance on choosing the right wire for various applications.

Stranded Wire vs. Solid Wire

Both stranded and solid wire have their unique benefits and drawbacks, making each suitable for specific applications. The primary differences between the two types of wire are:

- Flexibility: As previously mentioned, stranded wire is more flexible than solid wire due to its multi-strand construction. Solid wire, on the other hand, consists of a single solid conductor, which is more rigid and prone to breakage when subjected to bending or movement.

- Conductivity: Stranded wire typically has lower resistance and better conductivity than solid wire of the same gauge due to its increased surface area. However, this advantage may be offset by the higher possibility of oxidation or corrosion, which can occur between the strands of a stranded conductor.

- Cost: Stranded wire is generally more expensive than solid wire because of the added complexity of its construction and the increased amount of material required.

- Termination: Solid wire is easier to terminate with connectors, screw terminals, and other connection methods, as it can maintain its shape more effectively. Stranded wire may require additional steps, such as tinning or using specialized connectors, to ensure a secure connection.

Choosing the Right Wire for Your Application

When selecting between stranded and solid wire, consider the specific requirements of your application, including flexibility, durability, conductivity, and ease of installation. Here are some general guidelines to help you make an informed decision:

- If your application requires frequent movement or bending, stranded wire is the better choice due to its flexibility and resistance to metal fatigue.

- If you need to maximize conductivity while minimizing resistance, stranded wire may offer better performance, especially in larger gauge sizes.

- If cost is a significant factor, solid wire may be more economical, but keep in mind that its reduced flexibility could result in higher installation and maintenance costs in some situations.

- If ease of termination is crucial, solid wire is generally simpler to work with and requires fewer specialized tools or techniques.

Conclusion

Stranded wire, with its flexibility, durability, and increased conductivity, is an excellent choice for a wide range of applications, from electronics to automotive and industrial settings. However, it is essential to carefully consider the specific requirements of your project before selecting the appropriate wire type. By understanding the differences between stranded and solid wire and their respective benefits and drawbacks, you can make an informed decision that will contribute to the success and longevity of your wiring installation.