Explore the world of solid-state lasers, their operation, types, pros, cons, and diverse applications in our comprehensive guide.

Solid-State Lasers: An Overview

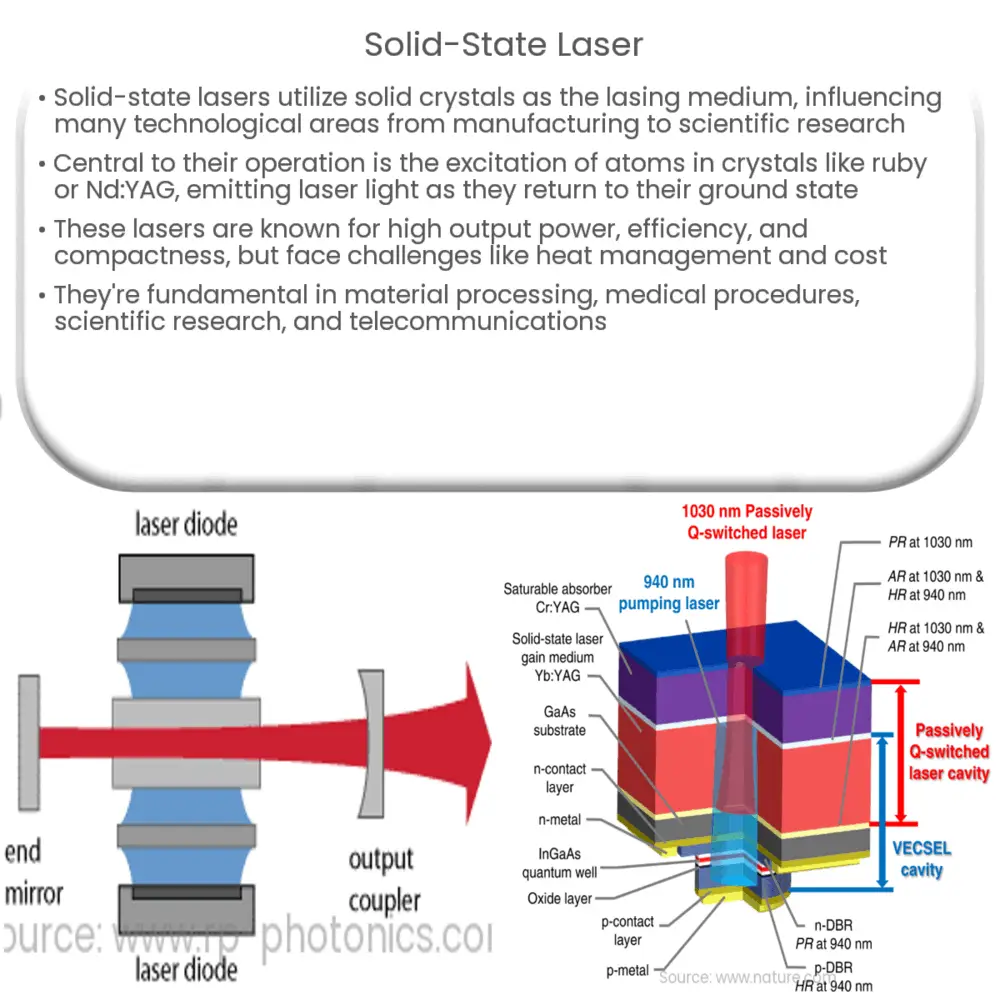

Solid-state lasers are a type of laser in which the lasing medium is a solid crystal, rather than a gas, liquid, or plasma. The term ‘solid-state’ refers to the physical state of the lasing material. These lasers have significantly shaped the course of laser technology and continue to play an essential role in various applications, from manufacturing and material processing to medical and scientific research.

Principle of Operation

At the heart of every solid-state laser is the lasing medium – a solid crystal like ruby or neodymium-doped yttrium aluminum garnet (Nd:YAG). The atoms in this crystal are excited to a higher energy state when they absorb photons from a pump source, often a flashlamp or another laser. This state of higher energy is known as an excited state. These excited atoms then emit photons, creating the laser light, as they return to their ground state.

Types of Solid-State Lasers

-

Ruby Lasers: The first working laser ever built was a ruby laser, developed by Theodore H. Maiman in 1960. This laser used a synthetic ruby rod as the gain medium. The ruby laser produces pulses of visible red light at a wavelength of 694.3 nanometers.

-

Neodymium-doped Yttrium Aluminum Garnet (Nd:YAG) Lasers: Among the most widely used solid-state lasers, Nd:YAG lasers can produce high-power continuous wave output. They operate in both the infrared (1064 nm) and green (532 nm) regions of the spectrum, with the green light produced through frequency doubling.

-

Titanium-doped Sapphire (Ti:Sapphire) Lasers: Known for their broad tuning range and ultrafast pulse durations, Ti:Sapphire lasers are commonly used in scientific research, particularly in the field of spectroscopy.

Advantages of Solid-State Lasers

-

High Output Power: Solid-state lasers can produce very high-power output, especially in the continuous wave mode.

-

Efficiency: Solid-state lasers can have high electrical-to-optical efficiency, particularly when diode-pumped.

-

Compact and Robust: Solid-state lasers tend to be more compact and robust compared to gas or liquid lasers, making them suitable for industrial applications.

Disadvantages and Challenges

Despite their numerous advantages, solid-state lasers also present certain challenges:

-

Thermal Issues: Due to their high-power output, solid-state lasers can generate significant heat. This heat must be effectively managed to prevent damage to the laser components and maintain optimal performance.

-

Cost: The initial cost of a solid-state laser can be higher than other types of lasers, especially for high-power systems. However, their operational cost over time can be lower due to their efficiency and robustness.

-

Complexity: Solid-state lasers can be complex, requiring careful design and precise alignment for optimal performance.

Applications of Solid-State Lasers

Solid-state lasers are used in a wide variety of applications:

-

Material Processing: Due to their high power and precision, they are widely used in cutting, welding, and drilling applications.

-

Medical Applications: Solid-state lasers find extensive use in various medical procedures, including eye surgery and dermatological treatments.

-

Scientific Research: Solid-state lasers are fundamental to a multitude of research areas, from spectroscopy to particle acceleration.

-

Telecommunications: Some solid-state lasers, especially fiber lasers, are used in telecommunications for signal transmission over long distances.

Conclusion

In summary, solid-state lasers, with their high power, efficiency, and robustness, have become a cornerstone of modern laser technology. While they present certain challenges, such as thermal management and initial cost, their benefits and wide range of applications make them an indispensable tool in many industries and scientific research. As technology advances, we can expect to see continuous improvements and innovations in the field of solid-state lasers, further expanding their potential uses and enhancing their performance.