Explore the world of SMD Inductors – their importance in modern electronics, functionality, types, design considerations, and mounting process.

SMD (Surface Mount Device) Inductors: An Overview

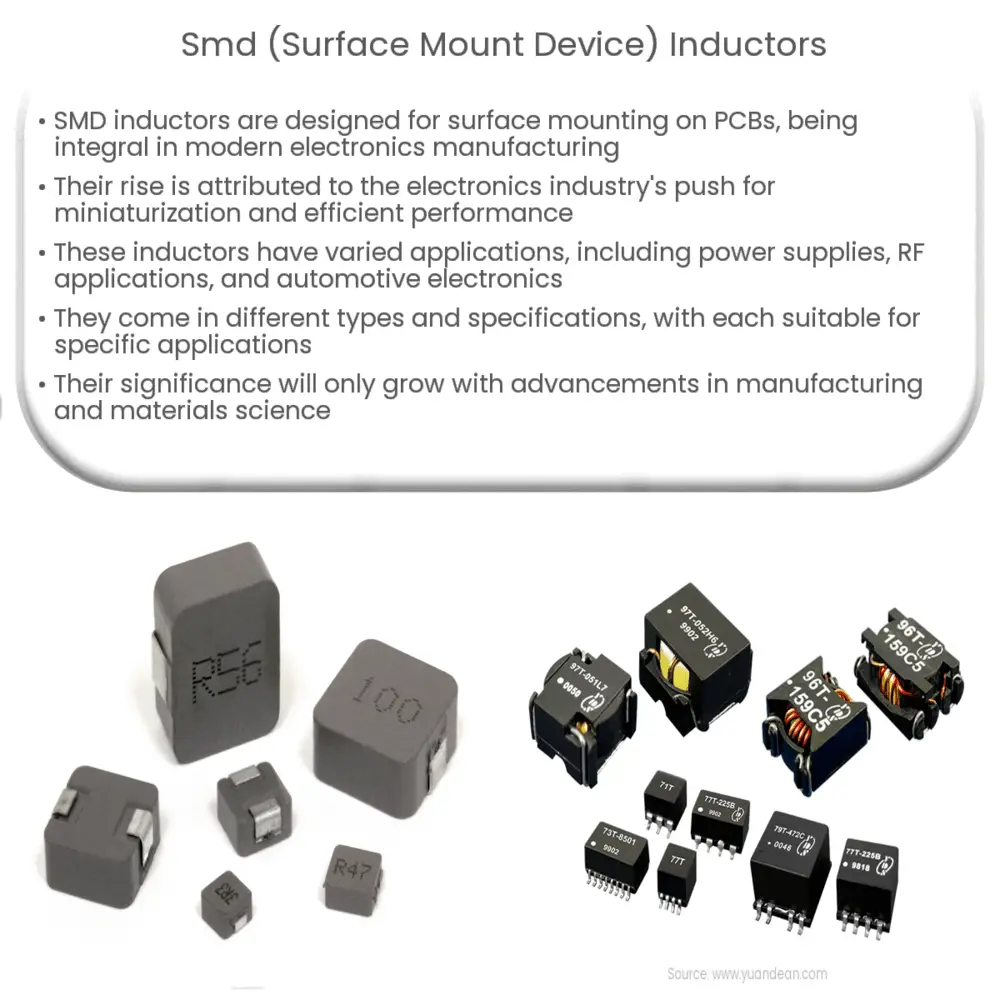

Surface Mount Device (SMD) inductors represent a specific category of inductors designed for surface mounting on printed circuit boards (PCBs). These innovative components are a part of the broader Surface Mount Technology (SMT) paradigm that dominates contemporary electronics manufacturing.

The Need for SMD Inductors

The increasing miniaturization in the electronics industry demands smaller components capable of performing at high efficiency. SMD inductors fulfil this requirement by offering compact size while maintaining superior electrical performance. They contribute significantly to the continued miniaturization of electronic products, enabling the creation of lightweight, slim, and portable devices.

Functionality and Applications of SMD Inductors

SMD inductors function as two-terminal passive electronic components that store energy in their magnetic field. They are integral in many electronic devices where they filter, resonate or couple signals. Some of the common applications of SMD inductors include:

- Power Supply Units: In power supplies, they manage energy storage and provide impedance to alternating current (AC) while passing direct current (DC).

- RF Applications: In Radio Frequency (RF) applications, they facilitate signal filtering, impedance matching, and frequency tuning.

- Automotive Electronics: In automotive systems, they aid in the management of power, noise suppression, and signal processing.

SMD Inductor Types and Specifications

SMD inductors come in various types, each with unique specifications suitable for different applications. The principal types of SMD inductors include wire-wound, multilayer, and film inductors, distinguished by their construction method. These types exhibit different inductance values, rated currents, self-resonant frequencies, and other performance characteristics, influencing their choice for specific applications.

Understanding SMD Inductor Markings

SMD inductors feature unique markings that indicate their inductance values and other specifications. Often these markings follow a three-digit or four-digit code, where the first two digits represent the significant figures, the third digit represents the multiplier (indicating the number of zeroes to follow), and the fourth digit (if present) signifies the tolerance in percentage.

Designing with SMD Inductors

When designing electronic circuits with SMD inductors, there are several factors to consider. Firstly, the choice of inductor depends on the application and the specific parameters required, such as inductance, current rating, and self-resonant frequency. Secondly, the footprint of the SMD inductor must fit within the layout of the PCB, taking into account the available space and the potential need for thermal management. Thirdly, consideration must be given to the inductor’s impact on the overall circuit performance, especially regarding power efficiency and signal integrity. Finally, factors such as cost, availability, and reliability of the inductors also play a critical role in the design process.

Manufacturing and Mounting of SMD Inductors

SMD inductors are manufactured using automated techniques that ensure high precision and consistency. These inductors are then mounted onto PCBs using Surface Mount Technology (SMT). This process involves applying solder paste to the PCB, placing the SMD inductor on the paste, and then passing the assembly through a reflow oven to melt the solder and secure the inductor to the board. This method allows for high-speed assembly and miniaturization, which are essential in today’s fast-paced electronics industry.

SMD Inductors: A Staple in Modern Electronics

In summary, SMD inductors, with their compact size and high performance, have become a staple in modern electronics. They play a pivotal role in a multitude of applications ranging from power supply units to RF applications and automotive electronics. As electronics continue to shrink in size while demanding higher efficiency and performance, the importance of SMD inductors cannot be overstated. They represent the continuous evolution in electronics, enabling innovations that shape our lives.

The ongoing advancements in manufacturing techniques and materials science promise even more efficient and reliable SMD inductors in the future. Therefore, a comprehensive understanding of these versatile components is essential for anyone involved in electronics design and manufacturing. By harnessing the full potential of SMD inductors, designers and manufacturers can continue to push the boundaries of what is possible in electronic technology.