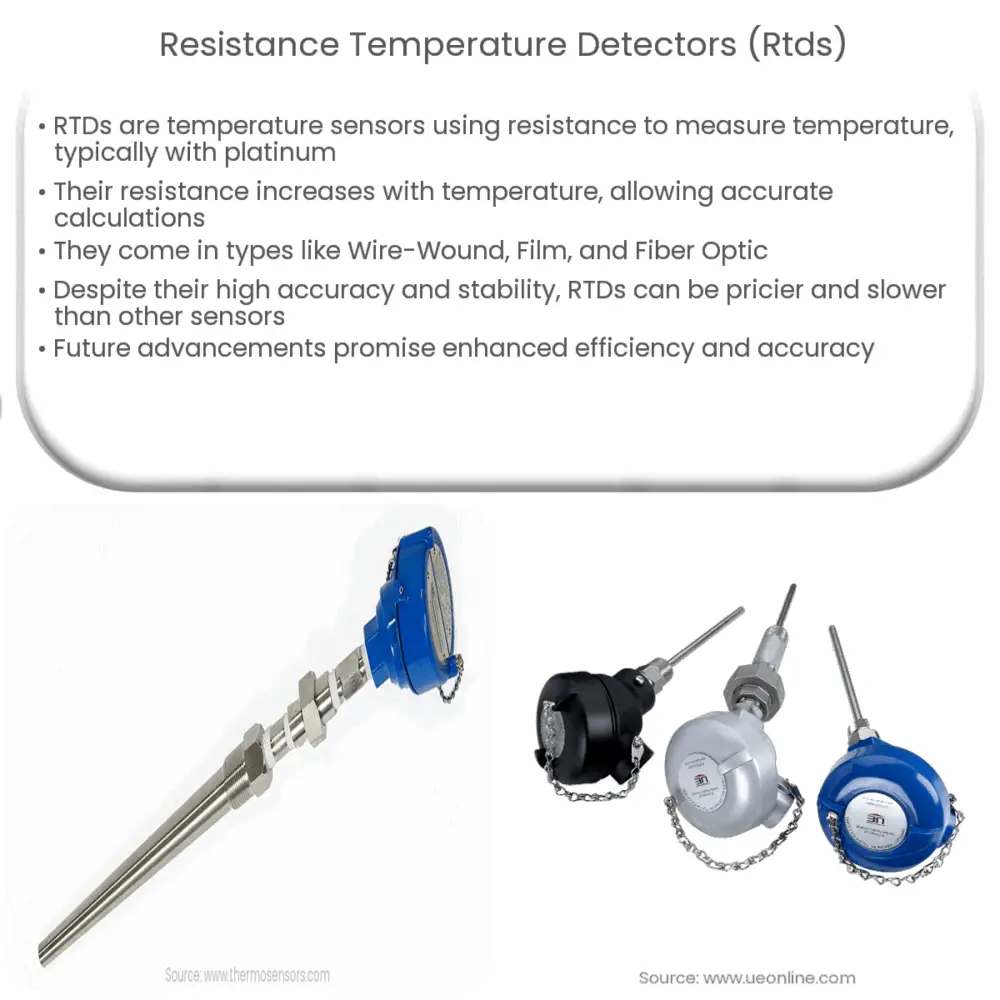

Explore the intricacies of Resistance Temperature Detectors (RTDs), their types, advantages, applications, and future potential in precise temperature measurement.

Understanding Resistance Temperature Detectors (RTDs)

Resistance Temperature Detectors (RTDs) are temperature sensors that use the principle of resistance to measure the surrounding temperature. These devices make use of a resistance element, typically made from pure platinum, which has the unique property of changing resistance linearly with temperature. Due to their accuracy and stability over time, RTDs are widely used in a range of industrial and scientific applications.

The Working Principle of RTDs

The fundamental concept behind the operation of an RTD is that the resistance of a metal increases with temperature. This effect is described by the equation R = R0(1 + αT), where R is the resistance, R0 is the resistance at a reference temperature (usually 0°C), α is the temperature coefficient of resistance, and T is the temperature. By measuring the resistance of the platinum element, the temperature can be calculated.

Types of RTDs

- Wire-Wound RTDs: These are one of the most common types of RTDs and are known for their high accuracy. They are constructed by winding a fine wire around a ceramic or glass core.

- Film RTDs: These are typically smaller than wire-wound RTDs and are made by depositing a very thin layer of platinum on a ceramic substrate.

- Fiber Optic RTDs: A relatively new type of RTD, these utilize fiber optics to measure temperature. They are especially useful in environments where electronic interference is a concern.

Advantages and Disadvantages of RTDs

- Advantages: RTDs offer excellent accuracy, stability, and repeatability. They also have a large temperature range, making them suitable for a wide variety of applications.

- Disadvantages: Despite their numerous benefits, RTDs are not without drawbacks. They are generally more expensive than other types of temperature sensors, and their response time can be slower due to the heat capacity of the platinum element. Furthermore, they require a current source to measure resistance, which can lead to self-heating and potentially impact accuracy.

In conclusion, the utilization of RTDs in temperature measurement is widespread due to their impressive accuracy and stability. However, their application should be carefully considered in relation to their potential limitations and the specific requirements of the intended application.

Applications of RTDs

RTDs are employed in a multitude of industrial and scientific applications due to their superior accuracy and stability. Some notable instances include:

- Process Control: In industries such as chemical, food and beverage, and oil and gas, RTDs are utilized for their precise temperature measurements, which are critical for process control.

- Laboratory Equipment: RTDs are often used in laboratory equipment such as incubators, autoclaves, and ovens for accurate temperature monitoring.

- Electronics: These sensors help in temperature management of electronic components, preventing overheating and thereby increasing the lifespan of these devices.

- HVAC Systems: In Heating, Ventilation, and Air Conditioning (HVAC) systems, RTDs provide necessary temperature feedback for system control and efficiency.

Choosing the Right RTD

When choosing an RTD, several factors need to be considered. Firstly, the temperature range of the application is important as RTDs are best suited for moderate to high-temperature ranges. Secondly, the level of accuracy required should be evaluated. While RTDs provide excellent accuracy, they are more expensive than other types of temperature sensors. Finally, the environmental conditions, such as potential exposure to vibrations or corrosive substances, can also impact the type of RTD chosen.

Future of RTDs

With advancements in technology, the future of RTDs looks promising. New materials and designs are continually being explored to increase their efficiency and cost-effectiveness. Furthermore, developments in digital technology are allowing for better signal processing and thus improved temperature readings. These advancements, along with the inherent advantages of RTDs, will likely continue to drive their use in temperature measurement applications.

Conclusion

In summary, Resistance Temperature Detectors (RTDs) are a fundamental tool in precise temperature measurement, bringing value to a wide array of industries and applications. Their accuracy, stability, and wide temperature range, though balanced by higher cost and slower response time, have secured their place in the realm of temperature sensors. Future advancements will likely expand their capabilities, offering even greater accuracy and flexibility. As with all technology, the key is understanding the strengths and limitations of RTDs and choosing the right tool for the specific requirements of each application.