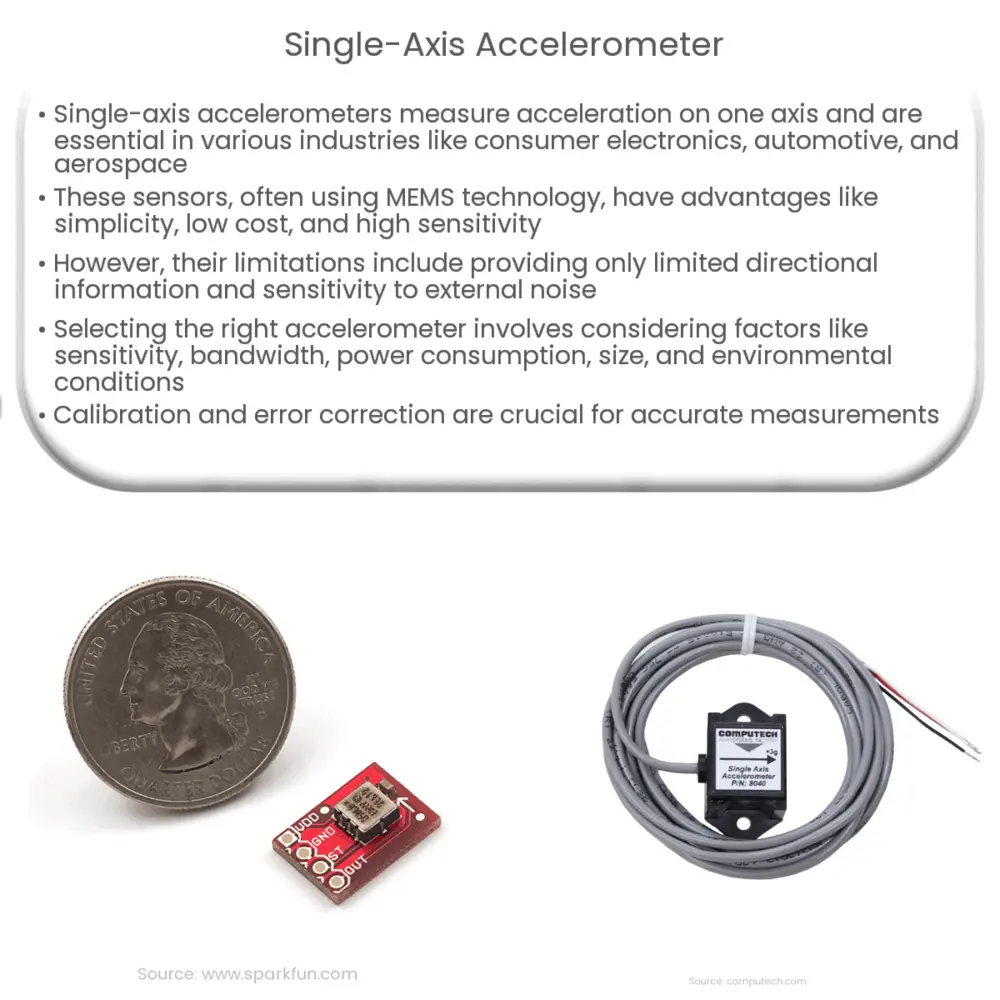

A single-axis accelerometer is a sensor that measures acceleration along one axis, used in consumer electronics, automotive, aerospace, and industrial applications.

Single-Axis Accelerometer: An Overview

Introduction

A single-axis accelerometer is a sensor that measures acceleration along a single axis. It is an essential component in a wide range of applications, from consumer electronics to automotive systems and aerospace engineering. This article will provide an overview of single-axis accelerometers, including their working principle, common applications, and advantages and limitations.

Working Principle

Accelerometers are devices that measure acceleration, which is the rate of change of velocity with respect to time. A single-axis accelerometer specifically measures acceleration along a single, predetermined axis. This type of sensor uses various technologies, such as piezoelectric, capacitive, and strain gauge, to convert the acceleration experienced by the device into an electrical signal that can be processed and analyzed.

The most common type of single-axis accelerometer is the Micro-Electro-Mechanical Systems (MEMS) accelerometer. MEMS technology integrates mechanical structures, sensors, actuators, and electronics on a single silicon substrate. These accelerometers often use capacitive sensing, where changes in capacitance caused by acceleration are measured and converted into an electrical signal. The small size, low power consumption, and relatively low cost of MEMS accelerometers have made them the preferred choice for many applications.

Common Applications

Single-axis accelerometers are used in a variety of applications, including:

- Consumer Electronics: These sensors are commonly found in smartphones, tablets, and gaming controllers to detect device orientation, enable gesture recognition, and provide user interface feedback.

- Automotive Systems: Accelerometers are used in vehicles for various purposes, such as measuring the acceleration of the vehicle for engine control, detecting sudden deceleration for airbag deployment, and monitoring tire pressure.

- Aerospace Engineering: Single-axis accelerometers are used to measure the acceleration experienced by spacecraft during launch, in-flight maneuvers, and re-entry, providing crucial data for guidance, navigation, and control systems.

- Industrial Applications: These sensors are used in machinery and equipment for vibration monitoring, fault detection, and preventive maintenance.

Advantages and Limitations

Single-axis accelerometers have several advantages, including:

- Simplicity: These sensors are relatively simple in design, making them easy to understand and implement in various applications.

- Low Cost: Due to their simplicity, single-axis accelerometers are generally more affordable than multi-axis accelerometers.

- High Sensitivity: Single-axis accelerometers can be designed with high sensitivity, allowing them to detect even small changes in acceleration.

However, single-axis accelerometers also have some limitations:

- Limited Directional Information: These sensors can only measure acceleration along a single axis, which may not be sufficient for applications requiring information about acceleration in multiple directions.

- Susceptibility to Noise: Single-axis accelerometers are sensitive to noise from external sources, such as vibrations and temperature changes, which can affect the accuracy of the measurements.

Choosing the Right Single-Axis Accelerometer

When selecting a single-axis accelerometer for a specific application, several factors should be considered:

- Sensitivity: Choose an accelerometer with a sensitivity appropriate for the expected acceleration range of your application. High-sensitivity accelerometers are suitable for detecting small changes in acceleration, while low-sensitivity accelerometers are ideal for measuring high acceleration levels without saturating the output signal.

- Bandwidth: The bandwidth of the accelerometer should match the frequency range of the acceleration signals you want to measure. A higher bandwidth allows for the accurate measurement of fast-changing acceleration signals, while a lower bandwidth is suitable for slow-changing signals.

- Power Consumption: In battery-powered applications, low power consumption is crucial. Select an accelerometer with a power consumption that fits the requirements of your application.

- Size and Weight: Depending on the application, size and weight constraints may be important factors. For example, in aerospace applications or wearable devices, compact and lightweight accelerometers are preferred.

- Environmental Conditions: The accelerometer should be able to withstand the environmental conditions of your application, such as temperature, humidity, and shock or vibration levels.

Calibration and Error Correction

Calibration is an essential step in ensuring the accuracy of single-axis accelerometer measurements. Calibration involves determining the relationship between the output signal of the accelerometer and the actual acceleration experienced by the device. This can be done using various methods, such as comparing the accelerometer’s output to a reference accelerometer or using a known acceleration source like gravity.

Error correction techniques can also be employed to improve the accuracy of accelerometer measurements. These techniques may include filtering to reduce noise, temperature compensation to account for temperature-induced changes in sensitivity and offset, and signal conditioning to improve linearity and dynamic range.

Conclusion

Single-axis accelerometers are versatile sensors that play a critical role in a wide range of applications. Their simplicity, affordability, and high sensitivity make them an attractive choice for many industries. However, it is essential to carefully consider the specific requirements of your application when selecting an accelerometer and apply appropriate calibration and error correction techniques to ensure accurate measurements. With a thorough understanding of the underlying technology and its capabilities, single-axis accelerometers can be effectively utilized to enhance the performance and functionality of various systems and devices.