Explore the workings, applications, advantages, and limitations of Shunt Wound DC motors, a versatile component in various industries.

Introduction to Shunt Wound DC Motors

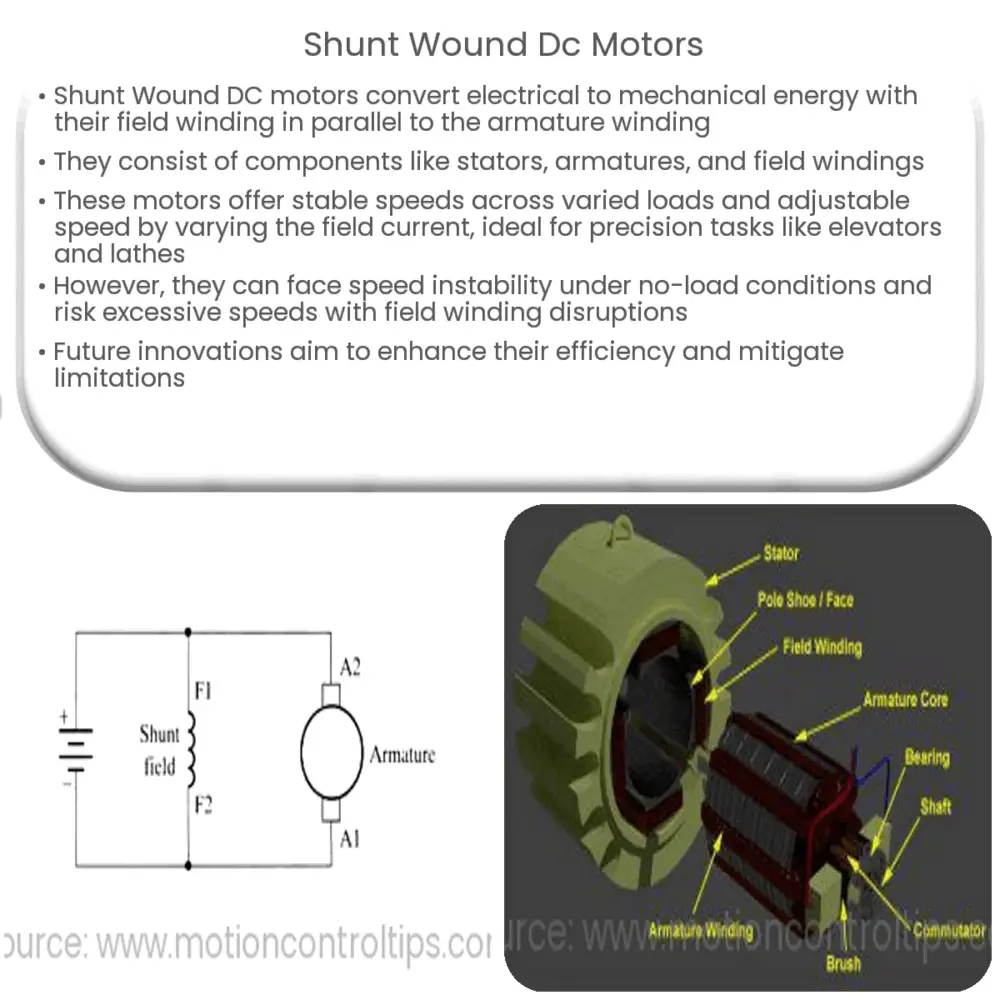

Direct Current (DC) motors are a vital component in many applications due to their ability to convert electrical energy into mechanical energy. One common type of DC motor is the Shunt Wound DC motor, characterized by the configuration of its field winding in parallel (shunt) with the armature winding. This unique configuration confers a set of distinct attributes and operational advantages.

Construction of Shunt Wound DC Motors

The fundamental components of a Shunt Wound DC motor include the stator, armature, commutator, brushes, and field windings. The stator provides a stationary magnetic field, and the armature acts as the rotor, generating a rotating magnetic field. The commutator and brushes form an integral part of the electrical circuit, facilitating the flow of current into the armature winding. The field windings, situated around the stator, play a pivotal role in this type of motor.

Working Principle

In a Shunt Wound DC motor, the field windings are connected in parallel (shunt) to the armature windings. Thus, both the windings are subjected to the same voltage, but the current through them varies based on their resistance. When power is applied, a magnetic field is established in the stator due to the current in the field windings. This field induces an electromotive force in the armature windings, causing the armature to rotate. The rotational speed of the motor is essentially dependent on the voltage applied and inversely proportional to the field current.

Characteristics and Applications

- Stable Speed: Shunt Wound DC motors maintain a constant speed over a wide range of loads, making them suitable for applications requiring stable and predictable performance.

- Adjustable Speed: By varying the field current, the speed of these motors can be controlled, adding to their versatility.

Shunt Wound DC motors find widespread use in industries and applications that require precise speed control and consistency, such as elevators, conveyors, lathes, and other machinery.

Despite their numerous advantages, Shunt Wound DC motors also have some limitations. For example, they are susceptible to speed instability under no-load conditions. Additionally, due to their parallel configuration, any break in the field winding circuit may result in an excessive speed, which could be detrimental to the motor and the driven machinery. Understanding these nuances is key to leveraging the benefits of these motors effectively.

Shunt Wound DC Motors: Pros and Cons

Like all technologies, Shunt Wound DC motors come with their unique set of pros and cons. On the plus side, their ability to maintain a steady speed across varying loads makes them ideal for precision tasks and applications requiring stable operational speed. They are also highly flexible in terms of speed control. This capability derives from the ability to alter the motor’s speed by adjusting the field current.

On the downside, Shunt Wound DC motors face a couple of significant challenges. Under no-load conditions, they can become unstable, leading to erratic operational speed. More critically, given their parallel configuration, a disruption in the field winding circuit can cause the motor to run at dangerously high speeds. This can potentially damage both the motor and the machinery it operates.

Future Perspectives

The demand for DC motors, including Shunt Wound DC motors, is expected to grow due to their widespread utility in various industrial applications. Innovations in this field aim to overcome their limitations and enhance their efficiency and performance. These may involve developing new materials for the windings, improving design aspects to mitigate speed instability issues, and employing advanced control techniques for better speed regulation.

Conclusion

In conclusion, Shunt Wound DC motors are a powerful and versatile type of DC motor with unique characteristics attributable to their specific winding configuration. They offer steady operation and adjustable speed, making them indispensable in many industrial applications. However, their weaknesses such as potential instability under no-load conditions and the risk of running at excessive speeds due to field winding circuit disruptions should be carefully managed. The future of these motors seems promising, with ongoing research and technological advancements set to further enhance their performance, making them even more valuable assets in the industrial sector.