Induction-electrostatic separators combine induction & electrostatic principles for precise particle separation in various industries.

Induction-Electrostatic Separator: A Revolution in Separation Technology

Introduction

Induction-electrostatic separators are a cutting-edge technology that has made significant strides in improving the efficiency and effectiveness of separating various materials in a wide range of industries. This technology combines the principles of electrostatic separation and induction-based separation techniques to yield highly accurate and precise separation of particles. In this article, we will delve into the principles behind induction-electrostatic separators, their applications, and the advantages they offer over traditional separation methods.

Principles of Induction-Electrostatic Separation

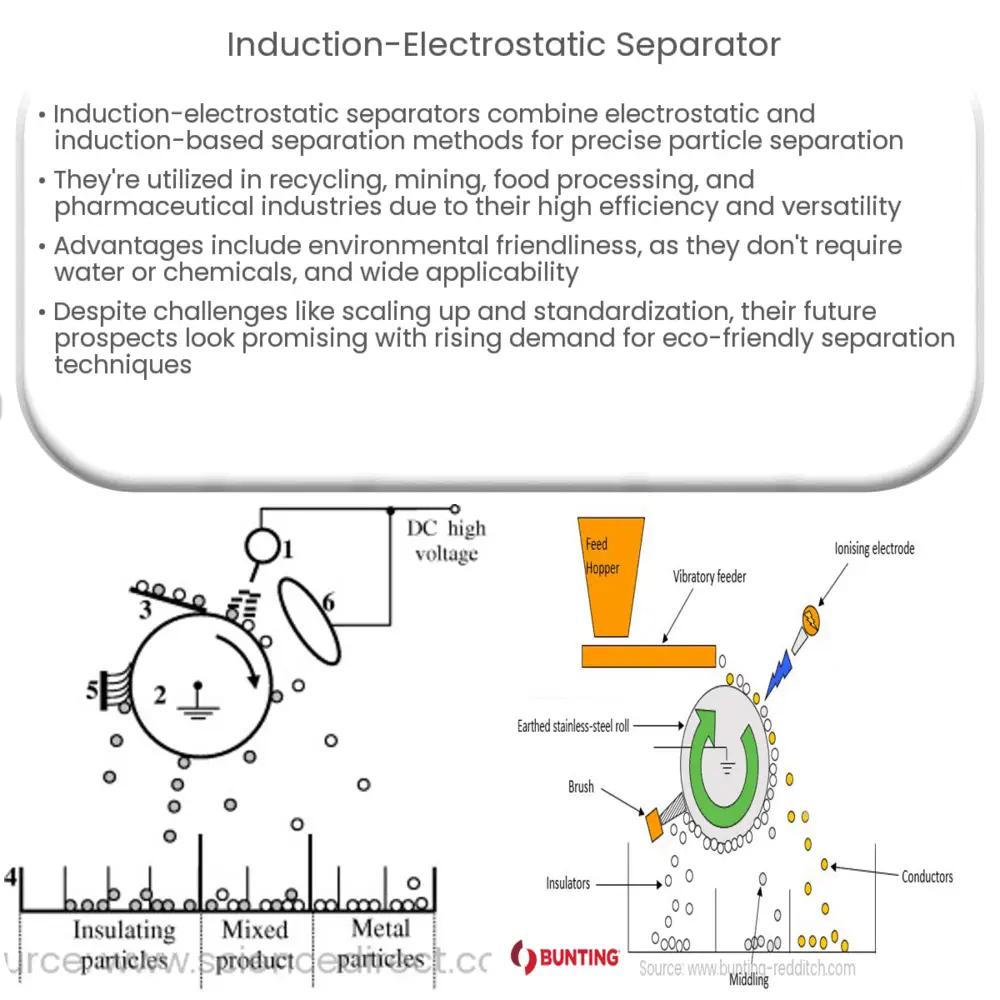

The induction-electrostatic separator operates based on two primary principles: induction and electrostatic separation. Induction separation involves the generation of an electromagnetic field that induces eddy currents in conductive particles, causing them to react differently to the applied magnetic field. Electrostatic separation, on the other hand, relies on the triboelectric effect, where different materials acquire different charges when they come into contact with each other or with a third material.

In an induction-electrostatic separator, a combination of these two principles is employed to separate a mixture of particles. The particles are first charged using a triboelectric charging device, and then they are subjected to an electromagnetic field generated by an induction coil. The interaction between the induced charges on the particles and the electromagnetic field causes them to move in different trajectories, allowing for their separation based on their electrical conductivities and particle sizes.

Applications of Induction-Electrostatic Separators

Induction-electrostatic separators have found applications in numerous industries due to their versatility and high separation efficiency. Some of the key industries that benefit from this technology include:

- Recycling: These separators are widely used in recycling plants for the recovery of valuable materials such as metals, plastics, and glass from mixed waste streams.

- Mining: Induction-electrostatic separators are employed in the mining industry to separate valuable minerals from gangue materials and to process ores with varying mineral compositions.

- Food processing: The food industry uses induction-electrostatic separators to remove contaminants and foreign materials from food products, ensuring their safety and quality.

- Pharmaceuticals: These separators play a crucial role in the pharmaceutical industry by ensuring the purity and quality of raw materials and finished products.

Advantages of Induction-Electrostatic Separators

Induction-electrostatic separators offer several advantages over traditional separation techniques, such as flotation, gravity separation, and magnetic separation. Some of the key benefits include:

- High separation efficiency: The combination of induction and electrostatic separation principles allows for highly precise and accurate separation of particles, resulting in improved product quality and reduced waste.

- Environmentally friendly: Induction-electrostatic separators do not require the use of water or chemicals, making them an eco-friendly option for industries that prioritize sustainability.

- Wide applicability: The versatility of induction-electrostatic separators enables them to be used in a variety of industries and for different materials, regardless of their size, shape, or conductivity.

Factors Affecting the Performance of Induction-Electrostatic Separators

Several factors can influence the performance and efficiency of induction-electrostatic separators, including:

- Particle size and shape: Particles with similar sizes and shapes can exhibit different separation behaviors due to variations in their electrical conductivities and the strength of the induced charges.

- Feed rate: The rate at which the material is fed into the separator can impact the separation efficiency. A higher feed rate may result in a reduced separation performance as the particles might not have enough time to interact with the electromagnetic field.

- Moisture content: The presence of moisture can affect the charging efficiency of the triboelectric charging device and, consequently, the performance of the separator. Dry conditions are generally more favorable for efficient electrostatic separation.

- Temperature: Temperature can influence the efficiency of the induction coil and the charging of particles. Extreme temperatures may lead to reduced separation efficiency and should be avoided.

Challenges and Future Prospects

Although induction-electrostatic separators have demonstrated significant advantages over traditional separation methods, there are still some challenges that need to be addressed:

- Scale-up: Scaling up the technology for large-scale industrial applications remains a challenge, as it requires the optimization of various parameters and the development of more efficient and robust designs.

- Standardization: The lack of standardized protocols for the operation and maintenance of induction-electrostatic separators can lead to variations in performance, making it difficult to compare and assess different separators in the market.

Despite these challenges, the future of induction-electrostatic separators looks promising. With continued research and development, it is expected that more efficient and advanced designs will emerge, further enhancing the separation capabilities of these devices. Additionally, as industries become more environmentally conscious, the demand for eco-friendly separation techniques is expected to grow, further propelling the adoption of induction-electrostatic separators.

Conclusion

Induction-electrostatic separators represent a significant advancement in separation technology, offering superior separation efficiency, environmental friendliness, and versatility compared to traditional methods. They have found applications in various industries, including recycling, mining, food processing, and pharmaceuticals. As research and development continue, it is anticipated that these separators will become increasingly popular, offering industries a more sustainable and efficient solution for particle separation.