Resonant pressure sensors detect pressure changes by measuring shifts in resonant frequency, offering high sensitivity and stability for diverse applications.

Resonant Pressure Sensor: An Overview

Introduction

Resonant pressure sensors have gained significant attention in recent years due to their high sensitivity, excellent stability, and versatility in various applications. In this article, we will provide an overview of resonant pressure sensors, including their operating principles, types, fabrication methods, and applications in various industries.

Operating Principle

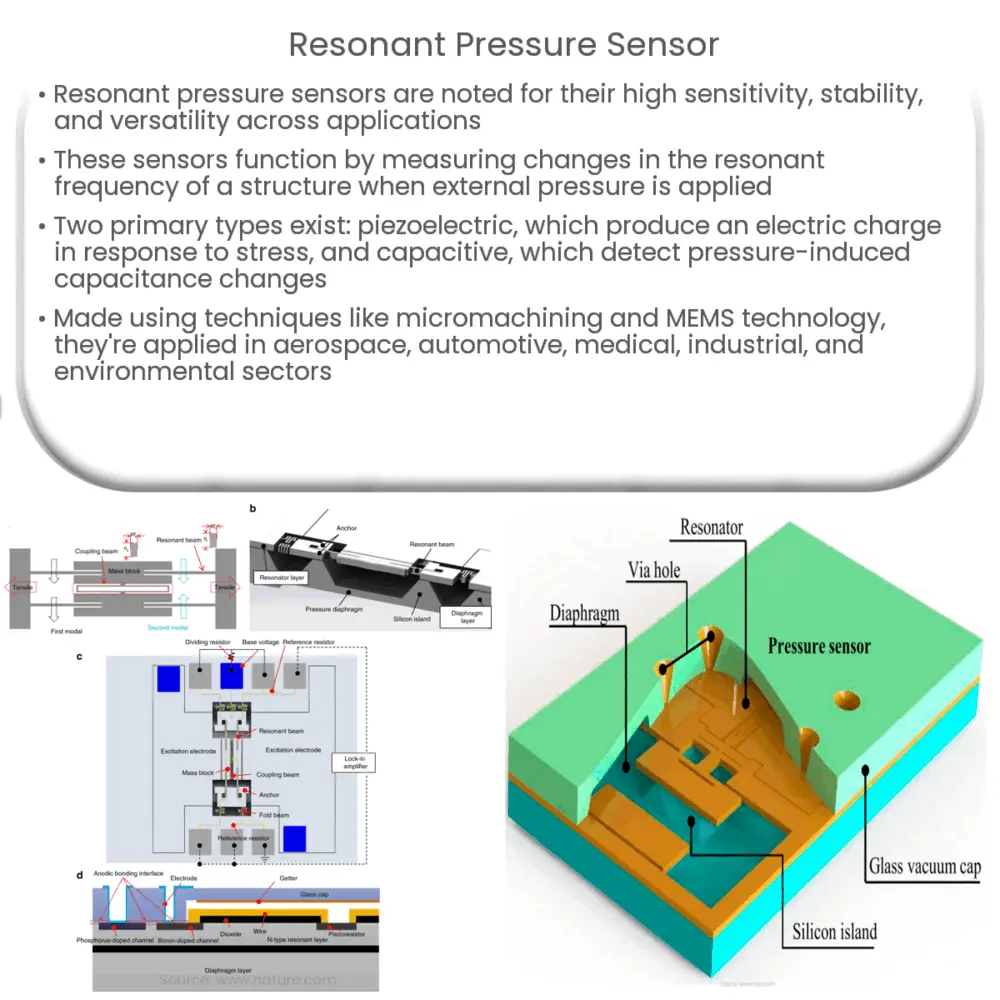

The fundamental principle behind resonant pressure sensors is the change in the resonant frequency of a mechanical structure when subjected to an external force or pressure. The resonant frequency is the natural frequency at which a structure vibrates when it is not subjected to any external forces. When an external pressure is applied to the structure, its resonant frequency changes, and this change can be measured and correlated to the applied pressure.

There are various types of resonant structures used in pressure sensors, such as diaphragms, beams, and plates. These structures are designed in such a way that they exhibit a high sensitivity to pressure changes, resulting in a larger change in resonant frequency for a given pressure change. This property makes resonant pressure sensors highly suitable for detecting small pressure changes in demanding applications.

Types of Resonant Pressure Sensors

Resonant pressure sensors can be broadly classified into two categories based on their transduction mechanism: piezoelectric and capacitive.

Piezoelectric Resonant Pressure Sensors

Piezoelectric resonant pressure sensors utilize the piezoelectric effect, which is the ability of certain materials to generate an electric charge in response to mechanical stress. When pressure is applied to a piezoelectric resonator, the resulting stress causes a change in the resonant frequency, which can be detected using an external electronic circuit. Piezoelectric sensors are known for their excellent sensitivity, temperature stability, and low power consumption.

Capacitive Resonant Pressure Sensors

Capacitive resonant pressure sensors rely on changes in capacitance to detect pressure-induced frequency shifts. A resonant structure is typically suspended between two electrodes, forming a variable capacitor. When pressure is applied to the structure, its deflection causes a change in the distance between the electrodes, which in turn changes the capacitance. This change in capacitance is then correlated to the applied pressure. Capacitive sensors are known for their high resolution, low hysteresis, and good linearity.

Fabrication Methods

Resonant pressure sensors are fabricated using various techniques, including bulk micromachining, surface micromachining, and MEMS (Micro-Electro-Mechanical Systems) technology. These fabrication methods allow for the production of miniaturized sensors with complex structures, making them suitable for a wide range of applications.

Bulk micromachining involves the selective etching of silicon substrates to create three-dimensional structures, while surface micromachining involves the deposition and patterning of thin films on a substrate. MEMS technology combines both micromachining techniques and integrates them with electronic circuits to create highly sensitive and compact sensors.

Applications of Resonant Pressure Sensors

Resonant pressure sensors find applications in various industries due to their high sensitivity, accuracy, and stability. Some of the key applications include:

Aerospace and Defense

In the aerospace and defense sector, resonant pressure sensors are used to monitor pressure changes in various systems, such as fuel lines, hydraulics, and environmental control systems. Their excellent sensitivity and stability make them ideal for measuring small pressure changes in high-stress environments.

Automotive

Resonant pressure sensors are used in the automotive industry for applications like tire pressure monitoring systems (TPMS), engine management, and transmission systems. These sensors provide real-time data on pressure changes, enabling improved vehicle performance, safety, and fuel efficiency.

Medical

In the medical field, resonant pressure sensors are used in devices such as blood pressure monitors, ventilators, and infusion pumps. Their high accuracy and sensitivity ensure precise and reliable measurements, which are critical for patient care and monitoring.

Industrial Process Control

Resonant pressure sensors are employed in various industrial processes for monitoring and controlling pressure levels in systems like pipelines, storage tanks, and reactors. Their high sensitivity and stability enable accurate pressure measurements, ensuring optimal process control and safety.

Environmental Monitoring

These sensors are also used for environmental monitoring applications, such as weather stations and air quality monitoring systems. They can accurately measure pressure changes in the atmosphere, providing valuable data for meteorological predictions and environmental assessments.

Conclusion

Resonant pressure sensors offer numerous advantages over traditional pressure sensing technologies, including high sensitivity, excellent stability, and a wide range of applications. The use of micromachining and MEMS technologies has enabled the production of miniaturized and highly sensitive resonant pressure sensors, making them suitable for various industries. As the demand for accurate and reliable pressure measurements continues to grow, resonant pressure sensors are expected to play an increasingly important role in a wide array of applications, from aerospace and automotive to medical and environmental monitoring.