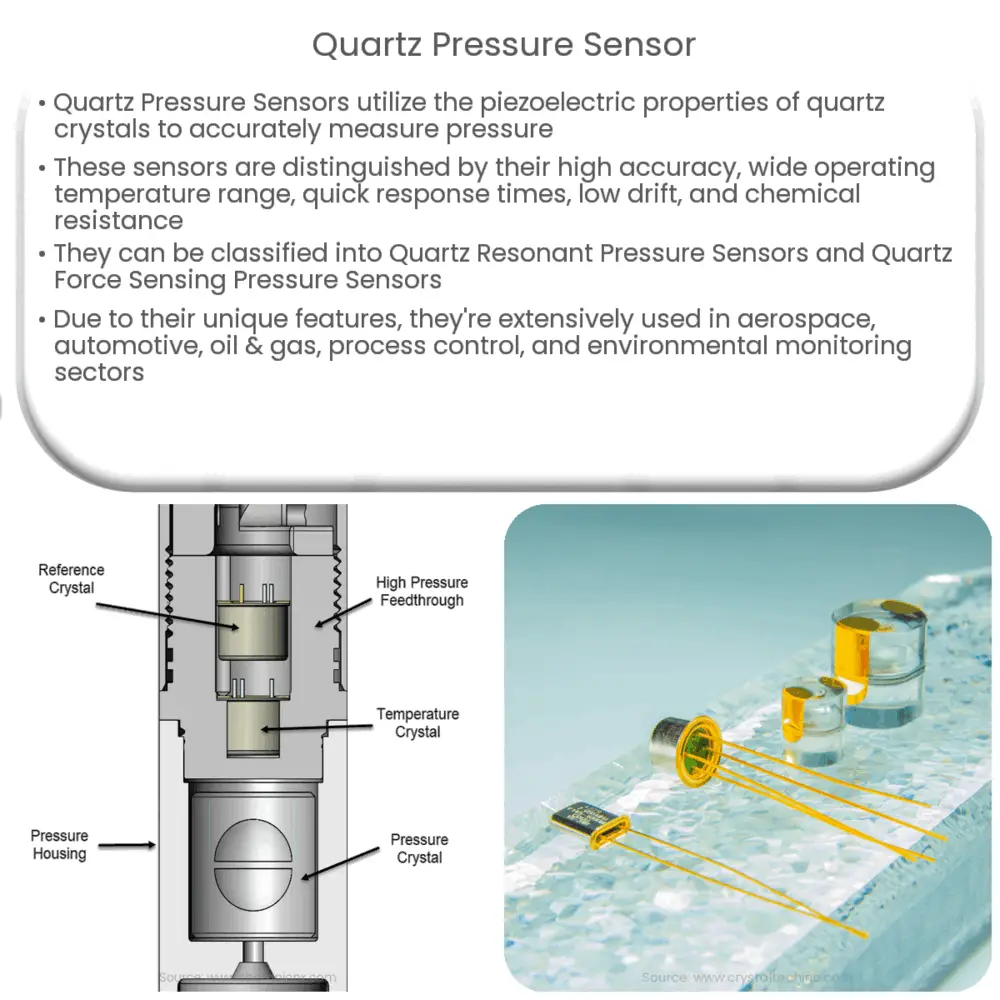

Quartz Pressure Sensors use piezoelectric properties of quartz crystals to measure pressure with high accuracy, stability, and wide temperature range.

Quartz Pressure Sensor: A Comprehensive Overview

Introduction

Pressure sensors are devices that measure the applied pressure of gases or liquids, converting it into an electrical signal. Among the various types of pressure sensors, Quartz Pressure Sensors have gained significant popularity due to their unique properties and wide-ranging applications. In this article, we will explore the key features, working principles, and advantages of Quartz Pressure Sensors.

What is a Quartz Pressure Sensor?

A Quartz Pressure Sensor is a type of pressure sensor that utilizes the piezoelectric properties of quartz crystals to measure pressure. Quartz is a naturally occurring mineral with a crystalline structure, known for its remarkable stability, precision, and sensitivity. When subjected to mechanical stress, such as pressure, quartz crystals generate an electrical charge proportional to the applied force. This makes them ideal for use in pressure sensing applications.

Key Features of Quartz Pressure Sensors

Quartz Pressure Sensors possess several noteworthy features, which contribute to their widespread usage in various industries:

- High Accuracy: Quartz Pressure Sensors are known for their exceptional accuracy, with some sensors capable of achieving accuracy levels as low as ±0.01% of full scale. This is due to the inherent stability of quartz crystals and their excellent linearity.

- Wide Temperature Range: These sensors can operate effectively over a broad temperature range, typically between -40°C and 200°C. This makes them suitable for use in extreme environments and high-temperature applications.

- High Frequency Response: Quartz Pressure Sensors offer fast response times and high-frequency response capabilities, making them ideal for dynamic pressure measurements, such as those required in shock tube experiments or combustion analysis.

- Low Drift: The low hysteresis and drift characteristics of quartz crystals ensure that these sensors maintain their accuracy and repeatability over time, making them highly reliable for long-term measurements.

- Chemical Resistance: Quartz is chemically inert and resistant to most common chemicals, making Quartz Pressure Sensors suitable for use in harsh chemical environments or applications involving corrosive fluids.

Working Principle of Quartz Pressure Sensors

The working principle of Quartz Pressure Sensors is based on the piezoelectric effect. When mechanical stress is applied to a quartz crystal, it generates an electrical charge proportional to the applied force. In a Quartz Pressure Sensor, the pressure applied to the sensing element, usually a diaphragm, is transmitted to the quartz crystal. This pressure causes the crystal to deform, generating an electrical signal that can be measured and processed to determine the pressure value.

Quartz Pressure Sensors typically consist of a sensing element, a quartz crystal, and an associated electronic circuitry for signal conditioning and processing. The sensing element is designed to be sensitive to pressure changes while being robust enough to withstand harsh environments and high-pressure levels. The quartz crystal serves as the transducer, converting the mechanical stress into an electrical signal. Finally, the electronic circuitry processes the signal and converts it into a standard output, such as a voltage or current, which can be easily interfaced with other instruments and systems.

Types of Quartz Pressure Sensors

There are two primary types of Quartz Pressure Sensors, based on the quartz crystal arrangement and sensing mechanism:

- Quartz Resonant Pressure Sensors: These sensors utilize the frequency change of a quartz crystal resonator under pressure. As pressure is applied to the sensing element, the resonant frequency of the crystal changes proportionally. By measuring this frequency change, the applied pressure can be accurately determined. Quartz resonant pressure sensors offer excellent long-term stability and high accuracy.

- Quartz Force Sensing Pressure Sensors: In these sensors, the pressure applied to the sensing element causes the quartz crystal to deform, generating an electrical charge proportional to the applied force. The generated charge is then measured and processed to determine the pressure value. Quartz force sensing pressure sensors provide fast response times and are suitable for dynamic pressure measurements.

Applications of Quartz Pressure Sensors

Quartz Pressure Sensors are employed in various industries and applications due to their unique properties and advantages. Some common applications include:

- Aerospace and Defense: In aircraft systems, space vehicles, and military applications, Quartz Pressure Sensors are used to monitor and control hydraulic systems, fuel systems, and cabin pressure, among others. Their high accuracy, reliability, and robustness make them well-suited for these demanding environments.

- Automotive: In the automotive industry, these sensors are used for engine management, transmission control, and tire pressure monitoring systems, where high accuracy and fast response times are critical for safety and performance.

- Oil and Gas: Quartz Pressure Sensors are used for downhole drilling applications, reservoir monitoring, and pipeline monitoring, due to their high-temperature capabilities and chemical resistance.

- Process Control: In industrial process control applications, such as chemical, pharmaceutical, and food processing plants, these sensors are used to monitor and control pressure in various stages of the manufacturing process, ensuring product quality and safety.

- Environmental Monitoring: In environmental monitoring systems, Quartz Pressure Sensors are used to measure atmospheric pressure, water level, and fluid pressure in natural resources and research applications.

Conclusion

Quartz Pressure Sensors have emerged as a preferred choice in various industries due to their exceptional accuracy, wide temperature range, high frequency response, low drift, and chemical resistance. With advancements in materials and manufacturing technologies, these sensors continue to evolve, offering improved performance and new applications. As the demand for accurate, reliable, and robust pressure sensing solutions grows, Quartz Pressure Sensors will undoubtedly play a critical role in meeting these needs across a wide range of industries and applications.