Piezoelectric pressure sensors convert mechanical pressure into electrical signals, offering high sensitivity, wide range, and durability for diverse applications.

Piezoelectric Pressure Sensors: An Overview

Introduction

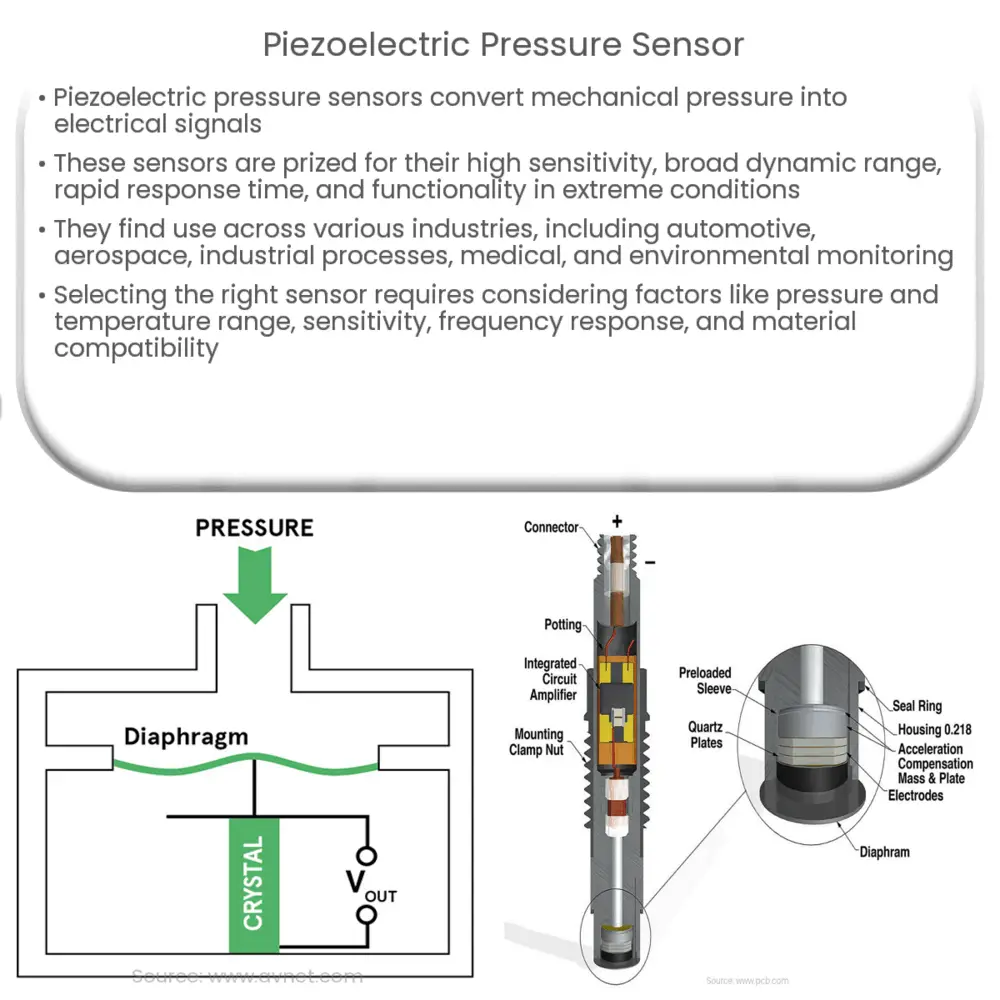

Piezoelectric pressure sensors are a unique class of devices that convert mechanical pressure into electrical signals. These sensors are increasingly popular due to their diverse applications, high sensitivity, and ability to operate in harsh environments. In this article, we will explore the principles behind piezoelectric pressure sensors, their advantages, and some common applications.

Principles of Piezoelectric Pressure Sensors

The term “piezoelectric” is derived from the Greek words “piezo,” meaning pressure, and “electric,” referring to electricity. Piezoelectric materials exhibit a specific property where they produce an electric charge when subjected to mechanical stress, such as pressure or force. This phenomenon, known as the piezoelectric effect, was first discovered in 1880 by the Curie brothers, Pierre and Jacques.

Piezoelectric pressure sensors consist of a piezoelectric material, usually a crystal or ceramic, that is sandwiched between two electrodes. When pressure is applied to the sensor, the piezoelectric material deforms, causing a voltage difference across the electrodes. This voltage can then be measured and correlated to the applied pressure.

Advantages of Piezoelectric Pressure Sensors

There are several advantages to using piezoelectric pressure sensors in various applications, including:

- High sensitivity: Piezoelectric materials can generate significant electrical signals in response to small mechanical forces, allowing for the detection of minute pressure changes.

- Wide dynamic range: These sensors can measure pressures over a wide range, from a few millibars to several hundred atmospheres, making them suitable for numerous applications.

- Fast response time: Due to their low mass and high stiffness, piezoelectric sensors can respond to pressure changes rapidly, making them ideal for dynamic and transient pressure measurements.

- Excellent stability: Piezoelectric materials are inherently stable and do not exhibit significant drift over time, ensuring long-term measurement accuracy.

- Resistance to harsh environments: Piezoelectric sensors can operate in extreme temperatures, pressures, and corrosive environments, making them suitable for use in challenging conditions.

Common Applications of Piezoelectric Pressure Sensors

Piezoelectric pressure sensors are employed in a variety of industries and applications, such as:

- Automotive: They are used in monitoring engine performance, tire pressure, and fluid pressure in braking systems.

- Aerospace: Piezoelectric sensors play a crucial role in measuring air pressure, cabin pressure, and fuel pressure in aircraft systems.

- Industrial processes: These sensors are used to monitor fluid pressure in pipes, tanks, and reactors, ensuring safe and efficient operations.

- Medical: Piezoelectric pressure sensors are utilized in blood pressure monitoring, respiratory therapy devices, and intracranial pressure monitoring.

- Environmental monitoring: They are employed in measuring atmospheric pressure, ocean depth, and groundwater pressure for various research and monitoring purposes.

Types of Piezoelectric Pressure Sensors

There are several types of piezoelectric pressure sensors, each designed for specific applications and requirements. Some of the most common types include:

- Piezoelectric diaphragm sensors: These sensors use a thin diaphragm to transfer pressure-induced mechanical stress to the piezoelectric material. They are widely used for low-pressure measurements and are particularly suitable for dynamic and transient pressure applications.

- Piezoelectric force sensors: These sensors measure pressure by converting the force applied to a rigid body into an electrical signal. They are commonly used in industrial applications where high accuracy and durability are required.

- Piezoelectric accelerometer sensors: These sensors detect changes in pressure by measuring the acceleration of a mass attached to the piezoelectric material. They are primarily used for vibration measurements and dynamic pressure applications.

Selecting the Right Piezoelectric Pressure Sensor

When choosing a piezoelectric pressure sensor for a specific application, it is essential to consider several factors, including:

- Pressure range: Select a sensor with an appropriate pressure range for your application to ensure accurate measurements.

- Sensitivity: Consider the required sensitivity level to detect the smallest pressure changes in your application.

- Temperature range: Ensure the sensor can operate within the temperature range of your application, particularly in extreme environments.

- Frequency response: Choose a sensor with a suitable frequency response for measuring dynamic and transient pressures.

- Material compatibility: Select a sensor with materials that are compatible with the media being measured, particularly in corrosive environments.

Conclusion

Piezoelectric pressure sensors are versatile devices that offer numerous benefits in various industries and applications. With their high sensitivity, wide dynamic range, fast response time, and ability to operate in harsh environments, they have become an integral part of many measurement systems. By understanding the principles behind these sensors and considering the factors that impact their performance, engineers and researchers can select the most suitable piezoelectric pressure sensor for their specific needs.