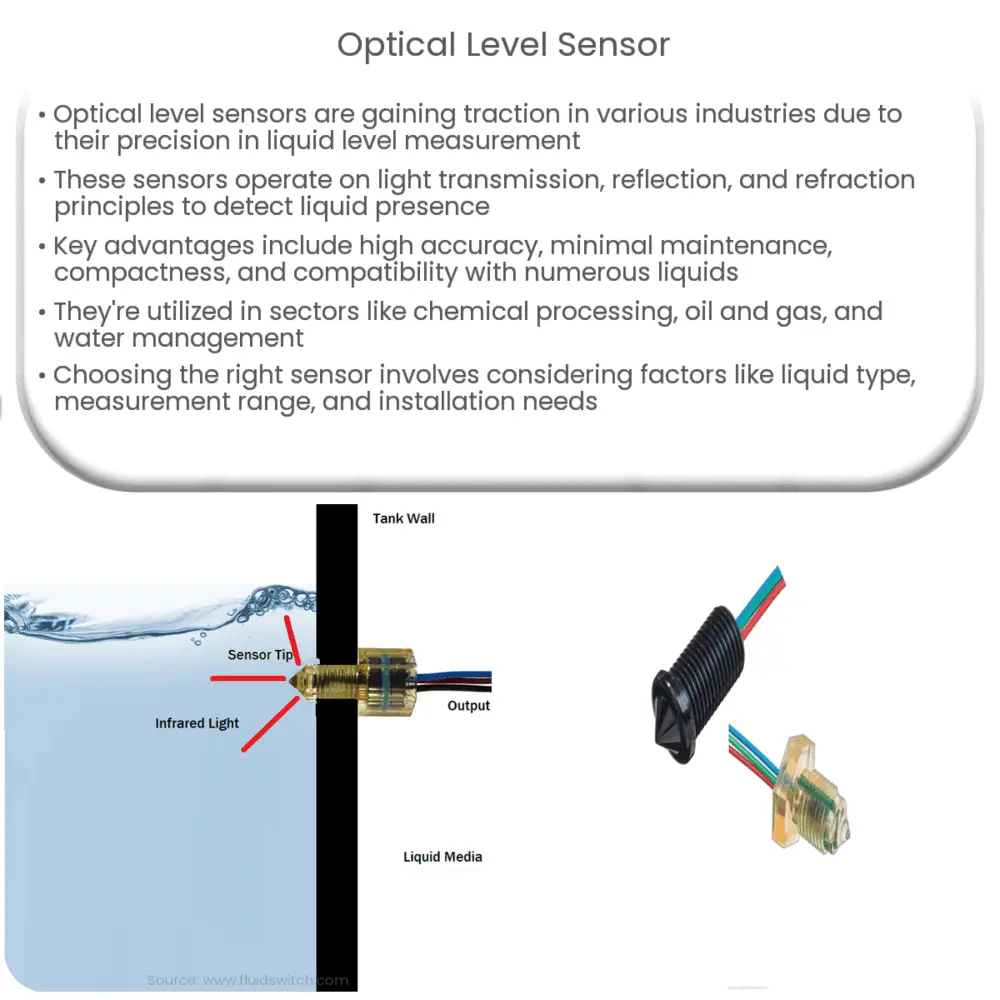

Optical level sensors provide accurate, reliable liquid level measurements for various industries, with low maintenance and high compatibility.

Optical Level Sensor: The Future of Liquid Level Measurement

Introduction

Optical level sensors are becoming increasingly popular in a wide range of industries, offering a reliable and efficient solution for liquid level measurement. These sensors have numerous applications, from monitoring fluid levels in storage tanks and process vessels to detecting liquid presence in pipelines and containers. This article will provide an in-depth look at the technology behind optical level sensors, their benefits, and their applications across various industries.

How Optical Level Sensors Work

At the core of an optical level sensor is the principle of light transmission, reflection, and refraction. These sensors use an infrared light source, typically a light-emitting diode (LED), to emit a beam of light into a prism or a light guide, which is in direct contact with the liquid being measured. When the liquid level is below the sensor’s detection point, the light beam is internally reflected within the prism or the light guide, and is received by a photodetector, producing a strong signal. However, when the liquid level rises and reaches the detection point, the light is refracted into the liquid, causing a significant decrease in the signal received by the photodetector. This change in signal strength is used to determine the presence or absence of liquid at the sensor’s detection point.

Benefits of Optical Level Sensors

Optical level sensors offer several advantages over traditional mechanical and electronic level sensing technologies, including:

- Accuracy and reliability: These sensors provide highly accurate and repeatable measurements, with little to no interference from surrounding environmental factors such as temperature, pressure, or humidity. Additionally, optical level sensors are immune to fluctuations in liquid density, viscosity, and dielectric constant, ensuring consistent performance in a variety of applications.

- Low maintenance: Optical level sensors have no moving parts, making them less prone to wear and tear, and reducing the need for regular maintenance. This leads to a lower total cost of ownership over the sensor’s lifetime.

- Compact design: These sensors have a small form factor, making them ideal for installation in tight spaces and applications where space is at a premium.

- High compatibility: Optical level sensors are suitable for use with a wide range of liquids, including water, oil, fuels, and chemicals. This makes them a versatile solution for many industries.

Applications of Optical Level Sensors

Optical level sensors are widely used in various industries due to their numerous benefits and high compatibility with different liquids. Some common applications include:

- Chemical processing: Monitoring fluid levels in storage tanks, pipelines, and process vessels.

- Oil and gas: Detecting leaks in pipelines, measuring fuel levels in storage tanks, and ensuring proper fluid levels in hydraulic systems.

- Water and wastewater management: Tracking water levels in reservoirs, monitoring sewage levels in wastewater treatment facilities, and controlling liquid levels in pumping stations.

- Food and beverage: Ensuring proper liquid levels in storage tanks and process vessels, as well as detecting product presence in pipelines and containers.

- Pharmaceutical and biotech: Monitoring liquid levels in storage tanks and process vessels, as well as detecting product presence in pipelines and containers.

Types of Optical Level Sensors

Optical level sensors can be broadly categorized into two types based on their design and functionality:

- Point Level Sensors: These sensors are designed to detect the presence or absence of liquid at a specific point within a container or vessel. Point level sensors are commonly used for applications such as overflow detection, low-level warnings, and high-level alarms.

- Continuous Level Sensors: Continuous level sensors provide real-time measurement of liquid levels across a range, offering more detailed information about the liquid level within a container or vessel. This type of sensor is ideal for applications that require precise control and monitoring of fluid levels, such as process control and inventory management.

Selection Criteria for Optical Level Sensors

When choosing an optical level sensor for a specific application, several factors should be considered to ensure the best performance and compatibility. These factors include:

- Liquid type: It is essential to select a sensor compatible with the liquid being measured, taking into account factors such as chemical compatibility, temperature, and pressure.

- Measurement range: The sensor should be able to cover the desired measurement range, from the lowest to the highest expected liquid levels.

- Accuracy and resolution: The required level of accuracy and resolution for the application should be considered, as this can impact the choice of sensor type and technology.

- Mounting and installation: The sensor should be compatible with the available mounting options and installation requirements for the specific application, including space constraints and accessibility for maintenance.

- Output options: Depending on the system integration requirements, the sensor should offer suitable output options, such as analog or digital outputs, that are compatible with the existing control or monitoring systems.

Conclusion

Optical level sensors offer an accurate, reliable, and versatile solution for liquid level measurement across various industries and applications. Their compact design, low maintenance requirements, and high compatibility with different liquid types make them an ideal choice for many applications, from chemical processing to water management. By considering factors such as liquid type, measurement range, accuracy, and mounting options, an appropriate optical level sensor can be selected to meet the specific requirements of any application, ensuring optimal performance and efficiency.