A milliohmmeter is a precise instrument used to measure low resistances in electrical and electronic applications, utilizing the four-wire Kelvin method.

Milliohmmeter: A Comprehensive Guide

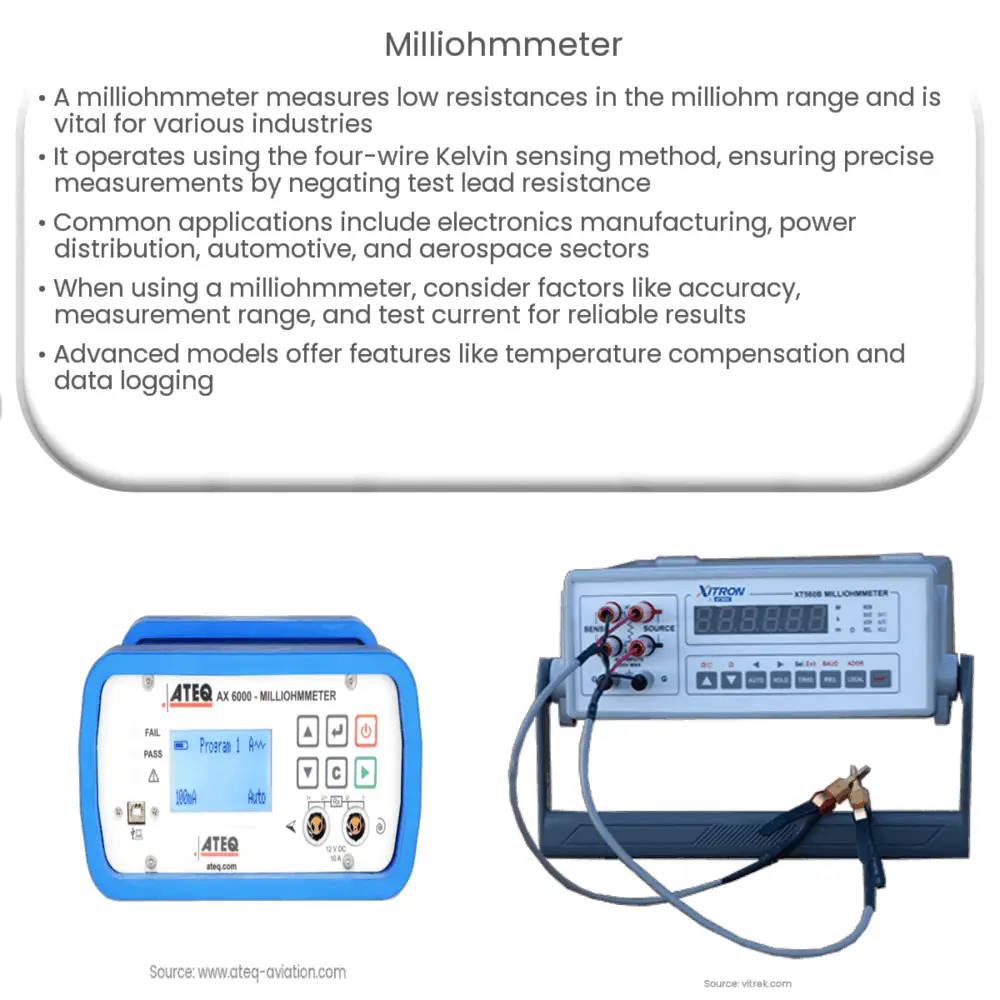

A milliohmmeter, also known as a microohmmeter or a low-resistance meter, is an essential tool for measuring low resistances in a variety of electrical and electronic applications. As the name suggests, a milliohmmeter measures resistances in the milliohm (mΩ) range, which is one-thousandth of an ohm. In this article, we will explore the operating principles, applications, and key considerations when using a milliohmmeter.

Operating Principles of a Milliohmmeter

At the core of a milliohmmeter’s functionality is the four-wire Kelvin sensing method, which enables accurate measurement of low resistances by eliminating the effect of test lead resistance. This method involves using two separate pairs of wires: one pair for injecting a known current into the device under test (DUT) and the other pair for measuring the voltage drop across the DUT. By using Ohm’s law (V=IR), the milliohmmeter calculates the resistance value with high precision.

Milliohmmeters usually generate a constant current source, which is crucial for maintaining accuracy and consistency in measurements. The current is typically in the range of milliamperes or microamperes, depending on the application and the device’s capabilities. The milliohmmeter’s internal circuits amplify the voltage drop across the DUT and convert it into a readable value on the display.

Applications of Milliohmmeters

Milliohmmeters find use in various industries and applications, including:

- Electronics manufacturing: Quality control and testing of circuit boards, connectors, and components require precise resistance measurements to ensure proper functionality and adherence to specifications.

- Power distribution: Milliohmmeters help in assessing the integrity of electrical connections, busbars, and cables in power distribution systems, where low resistance values are critical to minimize energy loss and heat generation.

- Automotive industry: These devices are used to test the electrical resistance of various components such as switches, relays, and fuses, and to diagnose problems in the electrical system.

- Aerospace and defense: In this sector, milliohmmeters are employed for testing and maintaining electrical systems, including wiring harnesses, connectors, and grounding points.

Key Considerations When Using a Milliohmmeter

When selecting and using a milliohmmeter, consider the following factors to ensure accurate and reliable measurements:

- Accuracy and resolution: Choose a milliohmmeter with suitable accuracy and resolution for your application. Accuracy is typically expressed as a percentage of the reading and a fixed value, while resolution refers to the smallest measurable change in resistance.

- Measurement range: Milliohmmeters offer different measurement ranges depending on their capabilities. Select a device that can measure the resistance values you expect to encounter in your application.

- Test current: Depending on the device, milliohmmeters generate different test currents. Choose a device that provides a suitable test current for your needs.

In the next section, we will discuss advanced features and accessories available for milliohmmeters, calibration procedures, and troubleshooting tips.

Advanced Features and Accessories

Modern milliohmmeters offer a variety of advanced features and accessories to improve measurement accuracy, ease of use, and versatility:

- Temperature compensation: Some milliohmmeters come with built-in temperature compensation to account for the temperature-dependent nature of resistance. This feature allows for more accurate measurements across a range of temperatures.

- Data logging and storage: Devices with data logging capabilities can store multiple measurements, allowing for easy analysis and comparison of data over time or between different test points.

- Interface options: Milliohmmeters with USB, Ethernet, or other communication interfaces can be connected to computers or other equipment for remote control, data transfer, and integration into automated test systems.

- Accessories: Specialized test leads, probes, and fixtures can improve measurement accuracy and repeatability by ensuring proper contact with the device under test.

Calibration and Maintenance

Regular calibration is essential for ensuring the accuracy and reliability of a milliohmmeter. Calibration involves comparing the milliohmmeter’s readings against known resistance values provided by a reference standard. Most manufacturers recommend calibrating the device annually or according to the usage and the specific requirements of your application.

Proper maintenance is also crucial for the performance and longevity of a milliohmmeter. Keep the device clean, store it in a protective case when not in use, and inspect test leads and probes for signs of wear or damage.

Troubleshooting Tips

When using a milliohmmeter, you may encounter issues that affect the accuracy or reliability of your measurements. Here are some common troubleshooting tips:

- Check connections: Ensure all connections between the milliohmmeter, test leads, and the device under test are clean and secure.

- Inspect test leads and probes: Damaged or worn test leads and probes can introduce errors in your measurements. Replace them as necessary.

- Avoid external influences: Electromagnetic interference, temperature changes, and mechanical stress can affect the accuracy of your measurements. Minimize these influences by using proper shielding, temperature compensation, and stable test setups.

- Perform a zero adjustment: Before taking measurements, perform a zero adjustment to account for any residual resistance in the test leads or internal circuits.

Conclusion

A milliohmmeter is an invaluable tool for measuring low resistances in various industries and applications. By understanding its operating principles, selecting the appropriate device for your needs, and following best practices for use and maintenance, you can ensure accurate and reliable resistance measurements. With advancements in technology, milliohmmeters continue to evolve, offering improved accuracy, advanced features, and better integration with other test and measurement equipment.