Explore the intricate world of micro-ohmmeters, their operation, applications, and the future trends in this comprehensive guide.

Introduction to Micro-Ohmmeters

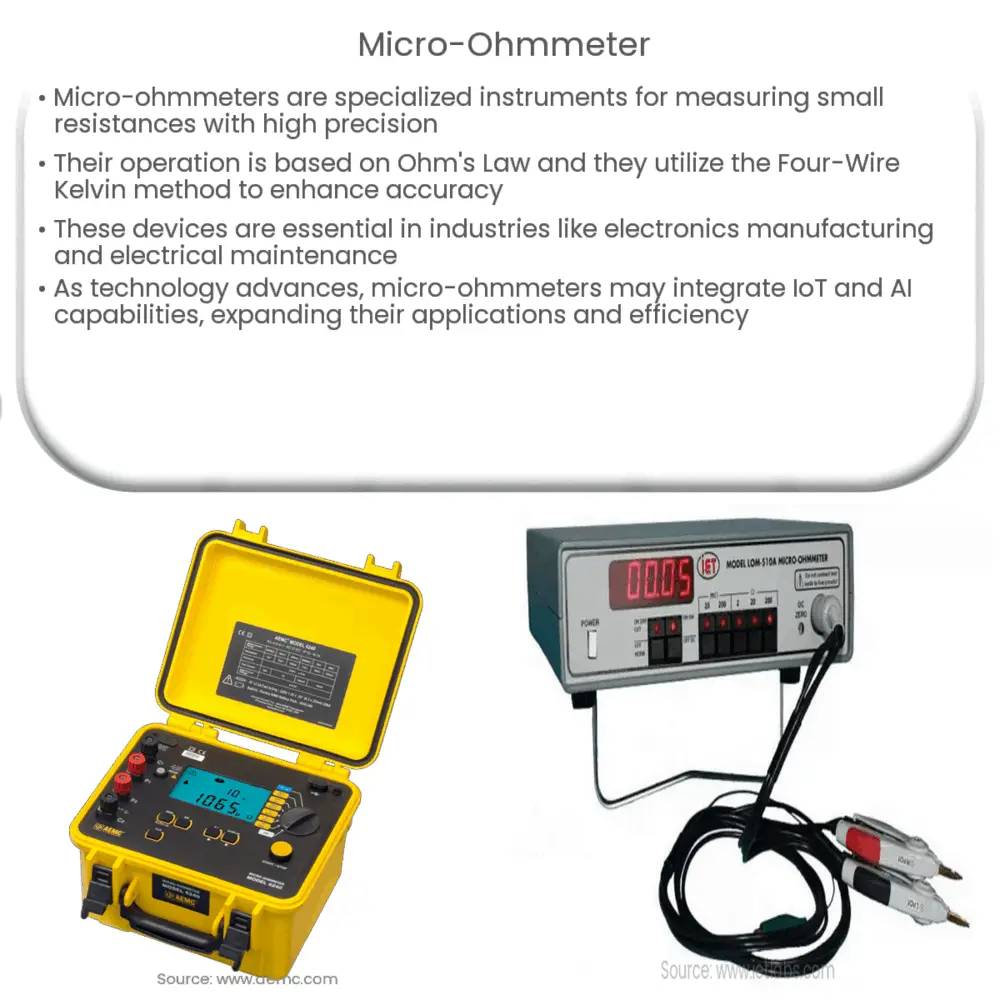

A micro-ohmmeter, as the name suggests, is a specialized instrument designed for measuring small resistances. These devices are remarkably precise, capable of determining resistance values in the micro-ohm range, hence their nomenclature.

Principles of Operation

The fundamental principle behind the operation of a micro-ohmmeter is based on Ohm’s Law, which states that the current flowing through a conductor between two points is directly proportional to the voltage across the two points. In the context of a micro-ohmmeter, the device measures the voltage drop across the test object when a known current is passed through it, and then calculates the resistance value based on these measurements.

The Four-Wire Kelvin Method

A notable method utilized by micro-ohmmeters to increase their measurement accuracy is the Four-Wire Kelvin technique. This method employs two sets of two wires each – one set for supplying the current, and the other for sensing the voltage drop. This approach effectively eliminates the resistance of the test leads from the measurement, ensuring a high level of accuracy.

- Current Leads: These carry the current from the micro-ohmmeter into the device under test.

- Voltage Leads: These are responsible for sensing and measuring the voltage drop across the device under test.

Applications of Micro-Ohmmeters

Micro-ohmmeters find use in a plethora of industries and applications. They are crucial in sectors that demand high precision in resistance measurement, like the manufacturing and maintenance of electrical and electronic components. Here are some of the common applications:

- Quality Control in Manufacturing: In the production of electrical components, micro-ohmmeters are used to verify if the resistance of the produced parts is within the specified tolerance levels.

- Electrical Maintenance: These devices play a critical role in the maintenance and troubleshooting of electrical systems. For instance, they can be used to locate high resistance connections that may lead to energy losses or even potential fire hazards.

While the above-mentioned points give an overview of micro-ohmmeters, there’s much more to these intricate devices, including various types, their construction, how they ensure precision, and the future trends in their technological advancements.

Varieties of Micro-Ohmmeters

Micro-ohmmeters come in various forms, each designed to cater to different needs and applications. Some are handheld and portable, useful for field measurements, while others are benchtop models that provide more detailed readings and often have additional features such as data logging and digital interfaces. Despite the form factor, all micro-ohmmeters share a common goal: to provide precise resistance measurements in the micro-ohm range.

Ensuring Precision

High accuracy is paramount when it comes to micro-ohmmeters. To ensure this, they are usually equipped with advanced features. These may include temperature compensation, which adjusts readings based on the temperature of the device under test, and zeroing functions, which allow the user to negate any offset errors.

Technological Advancements and Future Trends

With the rapid growth of technology, micro-ohmmeters have also evolved, becoming more accurate, reliable, and user-friendly. Modern devices often come with digital screens, easy-to-use interfaces, and connectivity options like USB and Bluetooth. These advancements allow for quick data transfer and real-time analysis, making the micro-ohmmeter an even more potent tool in various industries.

- Internet of Things (IoT) Integration: IoT devices are becoming increasingly common in industrial and manufacturing environments. Micro-ohmmeters with IoT capabilities can provide real-time data monitoring and analysis, making them a valuable asset in predictive maintenance and quality control.

- AI and Machine Learning: The future may see micro-ohmmeters integrated with AI and machine learning technologies, which could automate the process of data analysis, thereby improving efficiency and accuracy.

Conclusion

In conclusion, the micro-ohmmeter is an essential tool in the electronics and manufacturing industries, providing accurate measurements of small resistances. Its operation, based on Ohm’s Law and the Four-Wire Kelvin method, ensures high measurement accuracy, making it a reliable tool in various applications, from quality control in manufacturing to electrical system maintenance. With technological advancements like IoT integration and the potential incorporation of AI and machine learning, the role and capabilities of micro-ohmmeters are likely to further expand, enhancing their value and application in numerous sectors.