A Megohmmeter, or insulation tester, measures insulation resistance in electrical systems, ensuring safety, reliability, and preventing equipment failure.

Megohmmeter: The Essential Insulation Tester

Introduction

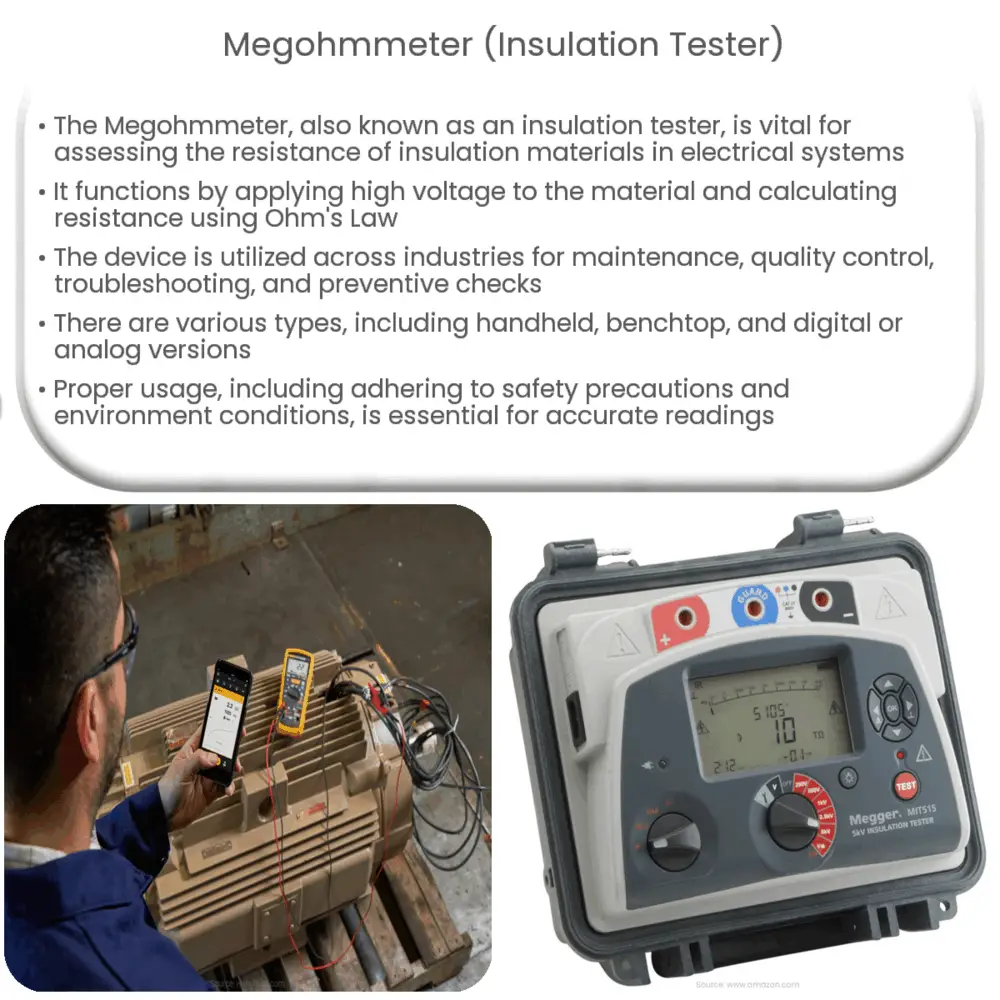

The Megohmmeter, commonly known as an insulation tester, is a crucial device in the electrical testing and maintenance field. It is used to measure the resistance of insulation materials, ensuring the safety and reliability of electrical systems. In this article, we will discuss the basic principles of a Megohmmeter, its applications, types, and best practices for using it effectively.

How a Megohmmeter Works

A Megohmmeter is an electrical instrument that measures resistance in the megaohm range. It operates by applying a high voltage, typically between 100V to 15,000V, across the insulation material to be tested. The device then measures the current flowing through the insulation and calculates the resistance using Ohm’s Law (R = V/I). High insulation resistance values indicate that the material is effectively preventing current leakage, which can lead to equipment damage and safety hazards.

Applications of Megohmmeters

Megohmmeters are widely used in various industries for insulation testing purposes, some of which include:

- Electrical Maintenance: Periodic insulation testing is necessary to ensure the safe operation of electrical systems and equipment. Megohmmeters can detect potential insulation failures before they result in catastrophic events, such as short circuits, fires, or equipment damage.

- Quality Control: Manufacturers of electrical components and devices use Megohmmeters to verify the quality of their products’ insulation, ensuring they meet industry standards and regulatory requirements.

- Troubleshooting: Megohmmeters are essential tools for identifying and diagnosing insulation-related issues in electrical systems, including moisture ingress, contamination, and physical damage.

- Preventive Maintenance: Routine insulation testing can reveal deteriorating insulation, allowing maintenance teams to address issues proactively and minimize the risk of equipment failure and downtime.

Types of Megohmmeters

Megohmmeters are available in various types and configurations to cater to specific testing requirements. The three main types of Megohmmeters are:

- Handheld Megohmmeters: These are portable, battery-powered devices ideal for field testing and on-site maintenance. They typically have a lower voltage range than other types and are suitable for testing low- to medium-voltage equipment.

- Benchtop Megohmmeters: These are stationary devices designed for laboratory and manufacturing environments. They offer higher accuracy, resolution, and voltage ranges than handheld models, making them suitable for testing high-voltage equipment and components.

- Analog and Digital Megohmmeters: Analog Megohmmeters use a needle and scale to display readings, while digital models use an LCD or LED display. Digital Megohmmeters generally offer higher accuracy, better resolution, and additional features, such as data storage and analysis capabilities.

When selecting a Megohmmeter, it is important to consider factors such as voltage range, accuracy, resolution, and additional features to ensure the device meets your specific testing requirements.

Best Practices for Using a Megohmmeter

Proper use of a Megohmmeter is crucial for obtaining accurate and reliable measurements. Follow these best practices to ensure optimal performance:

- Safety First: Always follow safety precautions when using a Megohmmeter, including wearing appropriate personal protective equipment (PPE) and adhering to lockout/tagout procedures.

- Test Environment: Ensure that the testing environment is free from moisture, dust, and other contaminants that may affect the insulation resistance readings.

- Device Calibration: Regularly calibrate your Megohmmeter to maintain accuracy and reliability. Adhere to the manufacturer’s recommendations for calibration intervals.

- Test Preparation: Disconnect the equipment or component being tested from its power source, and discharge any capacitors to prevent damage to the Megohmmeter and the equipment under test.

- Test Voltage Selection: Choose the appropriate test voltage based on the insulation material and equipment specifications. Consult the manufacturer’s guidelines for recommendations on the correct test voltage.

- Test Duration: Insulation resistance measurements may take time to stabilize, so allow sufficient time for the test to reach a steady reading.

- Temperature Correction: Insulation resistance is temperature-dependent, so it is essential to correct your measurements for temperature variations. Refer to the manufacturer’s guidelines or industry standards for temperature correction factors.

- Record Keeping: Maintain a record of insulation resistance test results, including equipment details, test conditions, and any observed trends. This will help in monitoring the insulation’s health over time and identifying potential issues before they escalate.

Conclusion

The Megohmmeter is an indispensable tool for testing the insulation quality of electrical systems and components. Understanding its operation, applications, types, and best practices will help you make informed decisions when selecting and using a Megohmmeter. Regular insulation testing using a Megohmmeter not only ensures the safety and reliability of your electrical systems but also prolongs the life of your equipment by preventing insulation-related failures and minimizing downtime.