Magnetic bevel gears are non-contact gear systems using magnetic force to transmit torque and motion, offering high efficiency and reduced wear.

Magnetic Bevel Gear: An Innovative Solution for Power Transmission

Introduction

As the world moves towards increased efficiency and sustainability in various industries, the demand for innovative power transmission solutions has grown significantly. One such development in this field is the magnetic bevel gear, a unique technology that has the potential to revolutionize how we transmit power. In this article, we will explore the concept, design, advantages, and applications of magnetic bevel gears.

Concept and Design

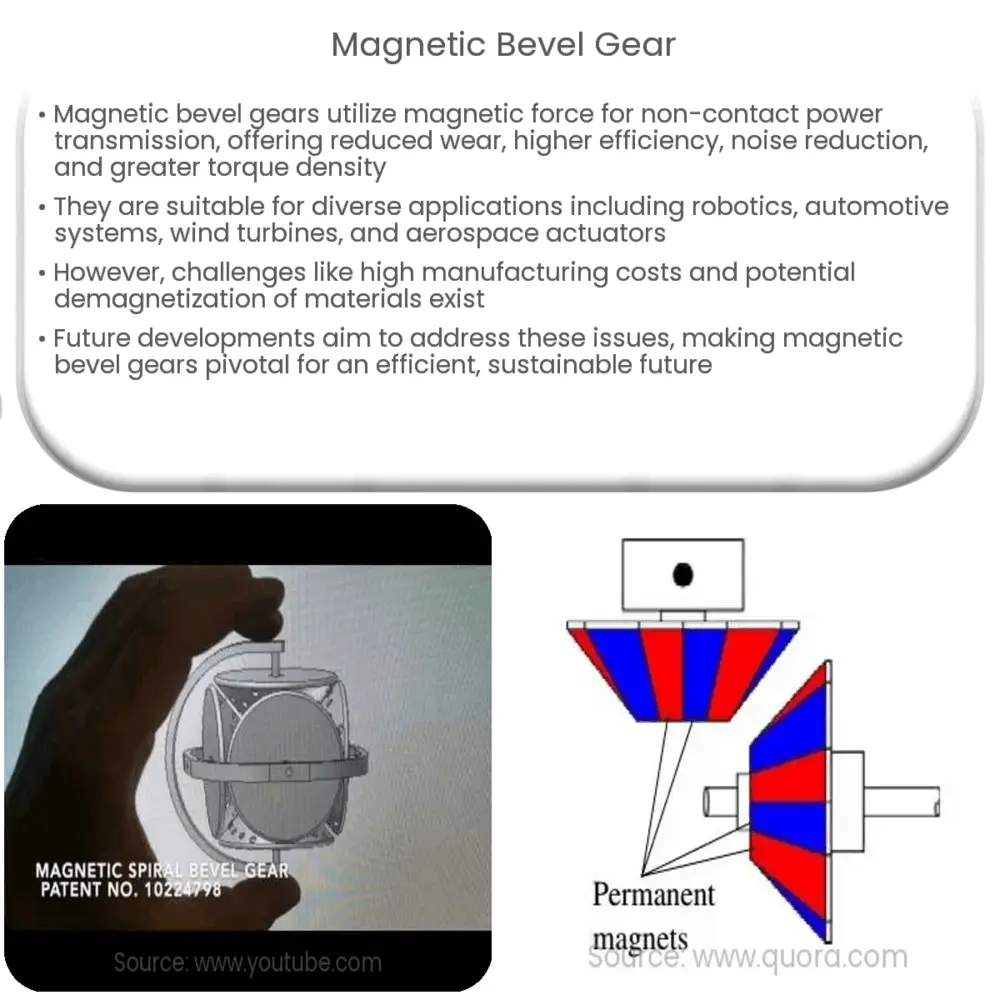

Magnetic bevel gears are a type of non-contact gear system that relies on the principle of magnetic force to transmit torque and motion between two rotating shafts. Typically, bevel gears are designed with teeth that mesh together to transfer power; however, in magnetic bevel gears, the tooth profiles are replaced by magnetic poles. These magnetic poles generate a repulsive or attractive force, depending on the orientation of the magnets, which ultimately drives the rotation of the gears.

The design of magnetic bevel gears consists of two main components: the magnetic ring and the ferromagnetic pole piece. The magnetic ring is made up of a series of permanent magnets arranged in a specific configuration, while the ferromagnetic pole piece is placed adjacent to the magnetic ring and is responsible for amplifying the magnetic field generated by the magnets. When the magnetic ring rotates, the resulting magnetic field interacts with the pole piece, creating a torque that causes the adjacent gear to rotate as well.

Advantages

Magnetic bevel gears offer several advantages over traditional mechanical gears, which stem from their unique non-contact design. Some of the key benefits include:

- Reduced wear and tear: Since there is no physical contact between the gear components, the wear and tear typically associated with mechanical gears is significantly reduced. This leads to longer lifespans and lower maintenance costs.

- Improved efficiency: Magnetic bevel gears have minimal friction and energy loss due to the absence of direct contact. As a result, they can achieve higher efficiency and transmit power more effectively.

- Noise reduction: The lack of physical contact also results in quieter operation, making magnetic bevel gears suitable for noise-sensitive applications.

- Higher torque density: The use of powerful permanent magnets enables magnetic bevel gears to achieve higher torque density compared to their mechanical counterparts. This allows for more compact designs and the potential for downsizing power transmission systems.

Applications

Given their unique properties, magnetic bevel gears are well-suited for a variety of applications across different industries. Some of the most common applications include:

- Robotics: The precise control and high torque density offered by magnetic bevel gears make them an attractive choice for robotic systems, such as robotic arms and manipulators.

- Automotive: The automotive industry is constantly seeking ways to improve efficiency and reduce noise levels. Magnetic bevel gears can be used in various components, such as power steering systems, to help achieve these goals.

Wind Energy

Wind turbines: Magnetic bevel gears are a promising solution for wind turbines due to their high efficiency, reduced noise levels, and low maintenance requirements. By replacing traditional gear systems, magnetic bevel gears can help enhance the overall performance and longevity of wind turbines.

Aerospace and Aviation

Aircraft actuators: The aerospace industry requires lightweight, reliable, and efficient power transmission systems. Magnetic bevel gears, with their high torque density and minimal friction, are well-suited for aircraft actuator systems, contributing to improved fuel efficiency and reduced weight.

Industrial Equipment

Conveyors and automation systems: Magnetic bevel gears are a viable option for various industrial applications, including conveyors and automation systems, where their high efficiency and low noise characteristics can greatly improve the performance and working environment.

Challenges and Future Developments

Despite their numerous advantages, magnetic bevel gears also face some challenges that need to be addressed to unlock their full potential. One of the main challenges is the high cost of manufacturing, as the production of powerful permanent magnets can be expensive. Additionally, magnetic materials may experience demagnetization over time, affecting the performance of the gear system.

Future developments in magnetic bevel gears are expected to focus on addressing these challenges through advancements in materials science and manufacturing processes. For instance, the development of new magnetic materials with higher energy density and improved resistance to demagnetization can significantly enhance the performance and durability of magnetic bevel gears. Furthermore, innovations in manufacturing techniques may help reduce production costs and make magnetic bevel gears more accessible for a wider range of applications.

Conclusion

Magnetic bevel gears are an innovative power transmission solution that offers numerous advantages over traditional mechanical gears, such as reduced wear and tear, improved efficiency, noise reduction, and higher torque density. With their potential applications across various industries, including robotics, automotive, wind energy, aerospace, and industrial equipment, magnetic bevel gears have the potential to revolutionize the way we transmit power. By overcoming current challenges and harnessing future developments in materials science and manufacturing techniques, magnetic bevel gears are poised to become a key technology in the pursuit of a more efficient and sustainable future.