Discover the benefits and applications of laser level sensors, their working principle, and how they revolutionize various industries with high accuracy.

Laser Level Sensor: Revolutionizing Industrial and Commercial Applications

Introduction

Laser level sensors are advanced devices that have revolutionized the way industries and commercial sectors measure and monitor liquid and solid levels. These sensors employ laser technology to provide highly accurate and reliable measurements, which are essential in various applications. In this article, we will discuss the working principle of laser level sensors, their advantages, and some common applications where they are making a significant impact.

Working Principle of Laser Level Sensors

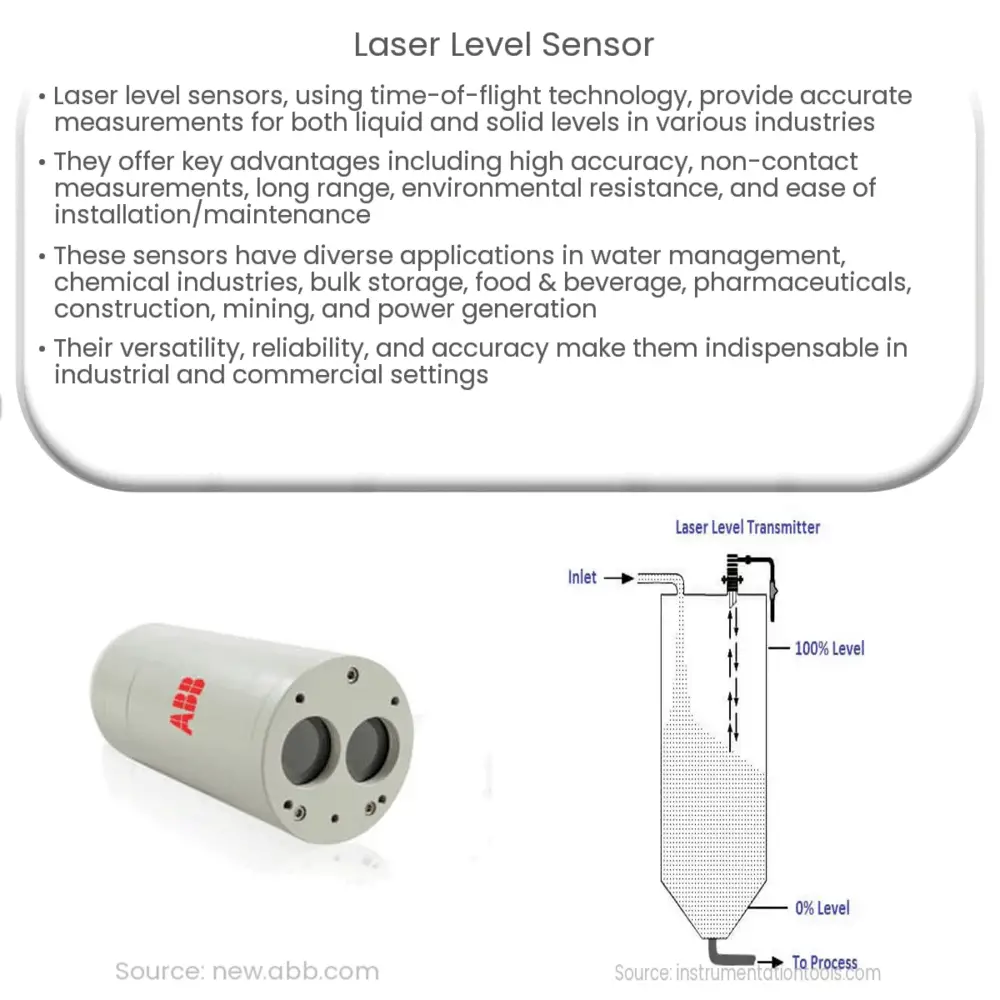

Laser level sensors operate based on the principle of time-of-flight (ToF) technology. A laser diode emits a laser pulse, which travels towards the target (liquid or solid surface) and then reflects back to the sensor’s receiver. The time taken for the laser pulse to travel to the target and return to the sensor is directly proportional to the distance between the sensor and the target. By calculating this time, the sensor can accurately determine the level of the target material.

Advanced processing algorithms and digital signal processing techniques are employed to filter out any noise or interference and provide accurate and reliable readings. Laser level sensors can measure levels over a wide range of distances, from a few inches to hundreds of feet, depending on the specific sensor model and application requirements.

Advantages of Laser Level Sensors

Laser level sensors offer several advantages over traditional level measurement technologies, such as capacitive, ultrasonic, and radar sensors. Some of the key benefits include:

- High Accuracy: Laser level sensors provide highly accurate measurements with minimal error, making them ideal for critical applications where precision is crucial.

- Non-Contact Measurement: These sensors do not require physical contact with the target material, making them suitable for measuring corrosive or abrasive materials and minimizing the risk of contamination.

- Long Range: Laser level sensors can measure levels over long distances, making them suitable for large tanks, silos, and other storage facilities.

- Reliability: Laser sensors are unaffected by environmental factors such as dust, humidity, and temperature, ensuring consistent performance and long service life.

- Easy Installation and Maintenance: These sensors are easy to install, and since they do not require physical contact with the target material, they generally require minimal maintenance.

Common Applications of Laser Level Sensors

Laser level sensors are used in a wide range of industries and applications due to their versatility and accuracy. Some common applications include:

- Water and Wastewater Management: Laser level sensors are used to monitor water levels in reservoirs, wells, and tanks, helping to optimize water distribution and prevent overflow or water scarcity issues.

- Chemical and Petrochemical Industry: These sensors are used to measure the level of liquid chemicals and petroleum products in storage tanks and process vessels, ensuring proper inventory management and safe operations.

- Bulk Solids Storage: Laser level sensors accurately measure the level of bulk solid materials, such as grains, minerals, and plastic pellets, in silos and other storage facilities, ensuring efficient inventory management and preventing overfilling or material shortages.

Food and Beverage Industry

In the food and beverage industry, laser level sensors are used to monitor the level of various liquid and solid ingredients in tanks, vats, and silos. They help maintain product consistency, quality, and safety by ensuring accurate measurements and avoiding cross-contamination.

Pharmaceuticals and Biotechnology

Laser level sensors play a critical role in the pharmaceutical and biotechnology sectors, where accurate and reliable level measurement is vital for maintaining strict quality control standards. These sensors can be used to measure the level of liquids, powders, and granules in mixing and storage vessels, ensuring the correct formulation of drugs and other products.

Construction and Mining

In construction and mining applications, laser level sensors can be used to monitor the level of materials such as cement, sand, and aggregates in storage silos, helping to maintain proper inventory levels and prevent stockouts or overfills. Additionally, these sensors can be utilized for monitoring the level of liquids in containment ponds and sumps, ensuring environmental compliance and minimizing the risk of groundwater contamination.

Power Generation

In power generation plants, laser level sensors are used to measure the level of fuels, such as coal and biomass, in storage facilities. Accurate measurement of fuel levels is crucial for maintaining the efficiency and safety of power generation operations. Furthermore, these sensors can be employed to monitor the level of cooling water in tanks and reservoirs, ensuring optimal cooling performance and preventing equipment damage due to overheating.

Conclusion

Laser level sensors have become an indispensable tool in various industries and commercial applications due to their high accuracy, reliability, and versatility. Their ability to provide non-contact, long-range measurements has made them an ideal choice for monitoring the level of liquid and solid materials in a wide range of settings. As technology continues to advance, laser level sensors are expected to become even more accurate, robust, and user-friendly, further enhancing their value in industrial and commercial applications.

References

- Levelling Instruments: Types, Working Principle, and Applications. (n.d.). Retrieved from https://theconstructor.org/surveying/levelling-instruments-types-working/2925/

- Time of Flight Principle for Level Measurement. (n.d.). Retrieved from https://www.vega.com/en/home_us/industries/water-wastewater/process-engineering/time-of-flight-principle-for-level-measurement

- Laser Level Measurement Devices: The Benefits & Applications. (2020, January 29). Retrieved from https://www.pulsar-pm.com/news/laser-level-measurement-devices-the-benefits-applications/