Impedance humidity sensors measure moisture levels by detecting changes in a sensing material’s electrical impedance, offering high sensitivity and fast response times.

Impedance Humidity Sensors: An Overview

Introduction

Humidity is a critical parameter in many applications, ranging from agriculture and meteorology to industrial processes and environmental monitoring. Accurate and reliable humidity measurements are essential for ensuring optimal conditions, maintaining product quality, and achieving energy efficiency. Impedance humidity sensors are one of the most popular and cost-effective methods for measuring humidity. This article will provide an overview of the working principles, advantages, and common applications of impedance humidity sensors.

Working Principle

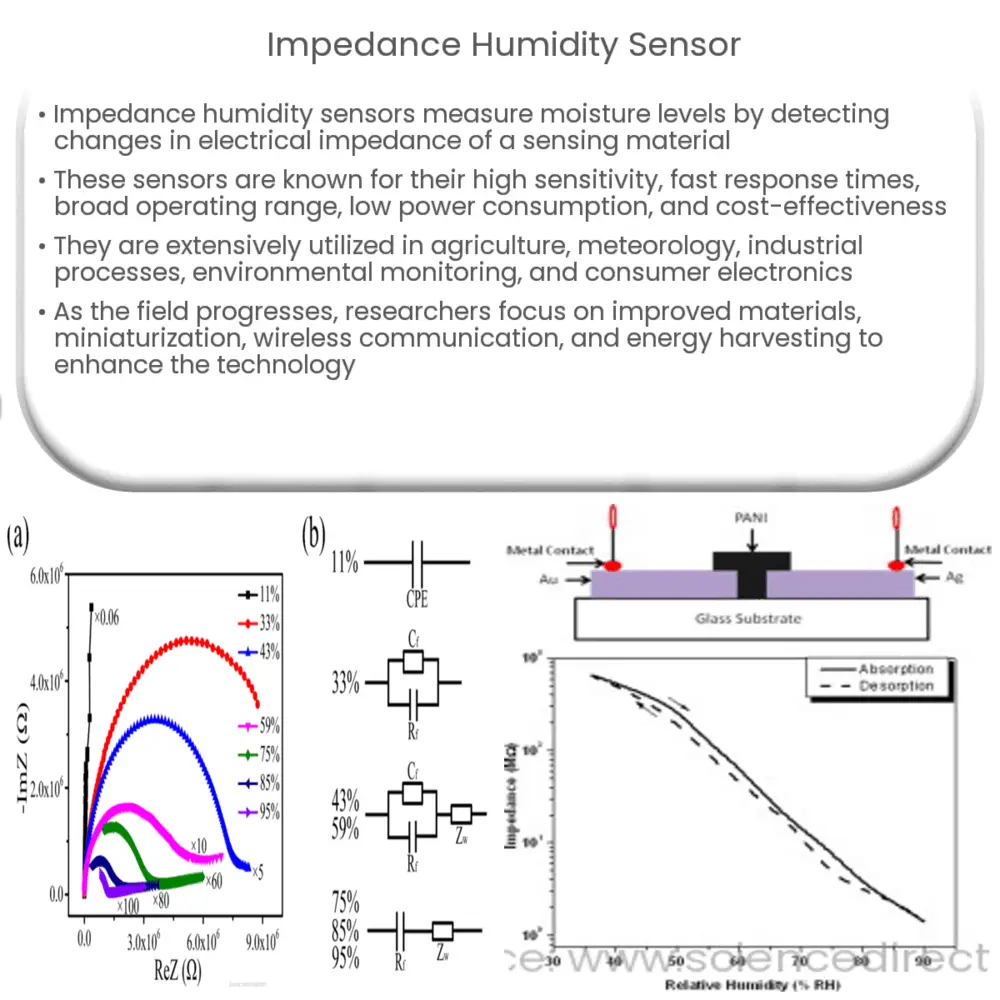

Impedance humidity sensors operate based on the principle that the electrical impedance of a sensing material changes with its moisture content. These sensors typically consist of a hygroscopic material, such as a polymer or ceramic, sandwiched between two electrodes. As the humidity in the environment increases, the moisture content of the sensing material also increases, leading to a decrease in its electrical impedance. This change in impedance can be measured and correlated to the relative humidity (RH) of the surrounding environment.

The most common type of impedance humidity sensor is the capacitive sensor. Capacitive humidity sensors consist of a dielectric material, such as a polymer or metal oxide, sandwiched between two conductive electrodes. As the dielectric material absorbs moisture, its dielectric constant changes, causing a change in the capacitance between the electrodes. This capacitance change can be measured and used to determine the humidity level in the environment.

Advantages of Impedance Humidity Sensors

Impedance humidity sensors offer several advantages over other types of humidity sensors, such as resistive and thermal sensors. Some of these benefits include:

- High sensitivity: Impedance humidity sensors can detect minute changes in humidity levels, making them suitable for applications that require high-resolution measurements.

- Fast response time: Due to their low thermal mass, impedance humidity sensors can quickly respond to changes in humidity, enabling real-time monitoring of environmental conditions.

- Wide operating range: Impedance humidity sensors can operate over a wide range of humidity levels and temperatures, making them suitable for various applications in different environments.

- Low power consumption: Impedance humidity sensors typically consume less power than other types of humidity sensors, making them ideal for battery-operated devices and energy-efficient applications.

- Cost-effectiveness: Impedance humidity sensors are relatively inexpensive to manufacture and maintain, making them an attractive option for budget-conscious applications.

Common Applications of Impedance Humidity Sensors

Impedance humidity sensors are widely used in various industries and applications, including:

- Agriculture and greenhouses: Monitoring and controlling humidity levels to ensure optimal plant growth and crop yield.

- Meteorology: Measuring atmospheric humidity for weather forecasting and climate research.

- Industrial processes: Controlling humidity levels in processes such as drying, curing, and cooling to maintain product quality and prevent defects.

- Environmental monitoring: Tracking humidity levels in indoor and outdoor environments for air quality assessments, mold prevention, and building performance evaluations.

- Consumer electronics: Integrating humidity sensors into devices such as smartphones, weather stations, and home automation systems for improved comfort and energy efficiency.

Selecting the Right Impedance Humidity Sensor

When choosing an impedance humidity sensor for a specific application, several factors should be considered:

- Accuracy: Different applications may require different levels of accuracy in humidity measurements. Be sure to select a sensor that meets the accuracy requirements of your application.

- Response time: The sensor’s response time should be fast enough to capture changes in humidity levels relevant to your application.

- Operating conditions: Ensure that the sensor can withstand the temperature and humidity ranges of the environment in which it will be used.

- Long-term stability: The sensor’s performance should remain consistent over time, with minimal drift or degradation.

- Size and form factor: The sensor should be physically compatible with the intended application, taking into consideration factors such as space constraints and mounting options.

Maintaining Impedance Humidity Sensors

To ensure accurate and reliable performance, impedance humidity sensors require proper maintenance and calibration. Some maintenance tips include:

- Cleaning: Regularly clean the sensor’s surface to prevent contamination and ensure accurate measurements. Follow the manufacturer’s recommendations for cleaning procedures and frequency.

- Calibration: Periodically calibrate the sensor to maintain accuracy and account for any drift or aging effects. Calibration should be done using a traceable humidity standard, such as a saturated salt solution or a humidity generator.

- Environmental considerations: Be aware of factors such as temperature, air flow, and chemical contaminants that may affect the sensor’s performance. Ensure the sensor is installed in a location with minimal exposure to these factors.

Future Developments in Impedance Humidity Sensing

As the demand for accurate and reliable humidity measurements continues to grow, new developments in impedance humidity sensing technology are emerging. Some areas of interest include:

- Improved materials: Researchers are exploring new materials for sensing elements, such as nanocomposites and hybrid materials, which offer enhanced sensitivity, stability, and selectivity.

- Miniaturization: Advances in microfabrication techniques are enabling the development of smaller, more compact humidity sensors, which can be integrated into a wider range of devices and applications.

- Wireless communication: The integration of wireless communication capabilities with impedance humidity sensors enables remote monitoring and control, as well as easy integration with IoT (Internet of Things) systems.

- Energy harvesting: The development of energy-harvesting technologies, such as solar cells and piezoelectric materials, can power impedance humidity sensors without the need for batteries or external power sources, enabling long-term, maintenance-free operation.

Conclusion

Impedance humidity sensors play a vital role in many applications, providing accurate and reliable humidity measurements for various industries and environments. By understanding their working principles, advantages, and applications, as well as proper selection and maintenance practices, users can ensure optimal performance and long-lasting reliability from these essential sensors. With ongoing advancements in materials, miniaturization, and wireless communication, impedance humidity sensing technology will continue to evolve, opening up new possibilities and applications in the future.