Improving magnetic materials involves material selection, modification, microstructure control, heat treatment, geometrical optimization, and circuit design.

Improving the Performance of Magnetic Materials

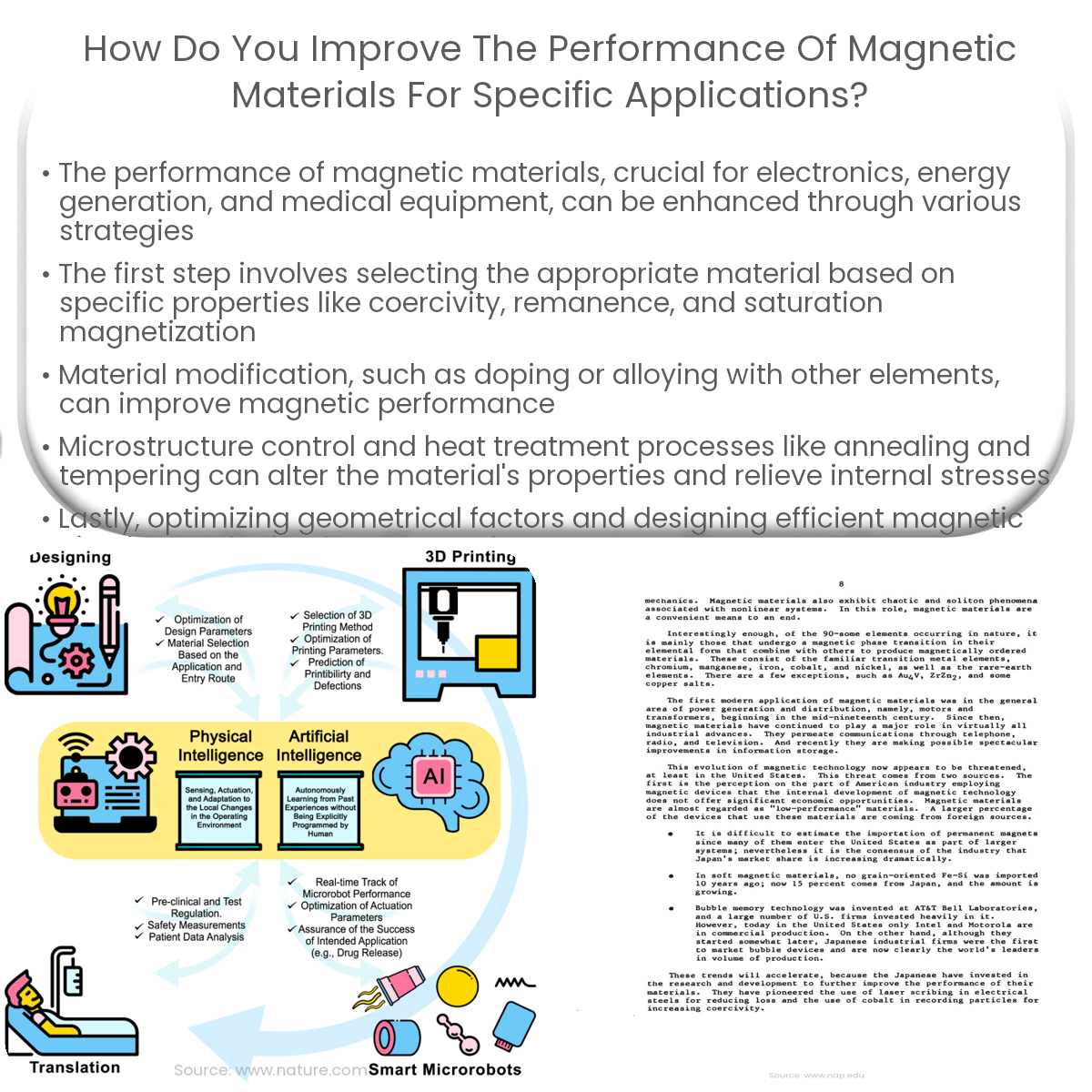

Enhancing the performance of magnetic materials is vital for various applications, such as electronics, energy generation, and medical equipment. Here, we discuss several strategies to improve magnetic materials for specific applications.

Material Selection

The first step in improving the performance of magnetic materials is to select the appropriate material for the desired application. Different magnetic materials have specific properties, such as coercivity, remanence, and saturation magnetization, which determine their suitability for specific applications. For instance, rare-earth magnets like neodymium-iron-boron (NdFeB) provide high magnetic energy products suitable for compact, high-performance devices.

Material Modification

Modifying the material’s composition can enhance its magnetic performance. This involves doping or alloying magnetic materials with other elements to achieve desired properties. For example, adding small amounts of cobalt (Co) to NdFeB magnets increases their coercivity, making them more resistant to demagnetization at high temperatures.

Microstructure Control

The microstructure of a magnetic material has a significant impact on its magnetic properties. Controlling the material’s grain size, phase distribution, and morphology can improve its performance. One common method is to use rapid solidification techniques, such as melt spinning, which produces fine-grained, highly coercive magnetic materials.

Heat Treatment

Heat treatment processes, like annealing and tempering, can be employed to optimize the magnetic performance of materials. These treatments can alter the material’s microstructure, improve its magnetic properties, and relieve internal stresses caused by manufacturing processes.

Optimizing Geometrical Factors

The shape and size of a magnetic component are critical factors in determining its performance. By optimizing the geometry of the component, it’s possible to improve its magnetic properties, such as increasing the magnetic field strength or reducing the magnetic losses. This can be achieved through careful design and advanced manufacturing techniques, such as additive manufacturing or precision machining.

Magnetic Circuit Design

Designing efficient magnetic circuits is essential for optimizing the performance of magnetic materials. This involves selecting the appropriate magnetic materials, minimizing magnetic losses, and ensuring proper magnetic field distribution. The use of computer simulations, like finite element analysis (FEA), can help in designing and optimizing magnetic circuits for specific applications.

In conclusion, improving the performance of magnetic materials requires a combination of material selection, composition modification, microstructure control, heat treatment, geometrical optimization, and magnetic circuit design. These strategies ensure the development of high-performance magnetic materials for various applications, meeting the growing demands of modern technologies.