To design a PCB layout, create a schematic, choose the PCB type, place components, route traces, add ground and power planes, perform a DRC, and generate Gerber files.

Designing a PCB Layout for an Electric Circuit

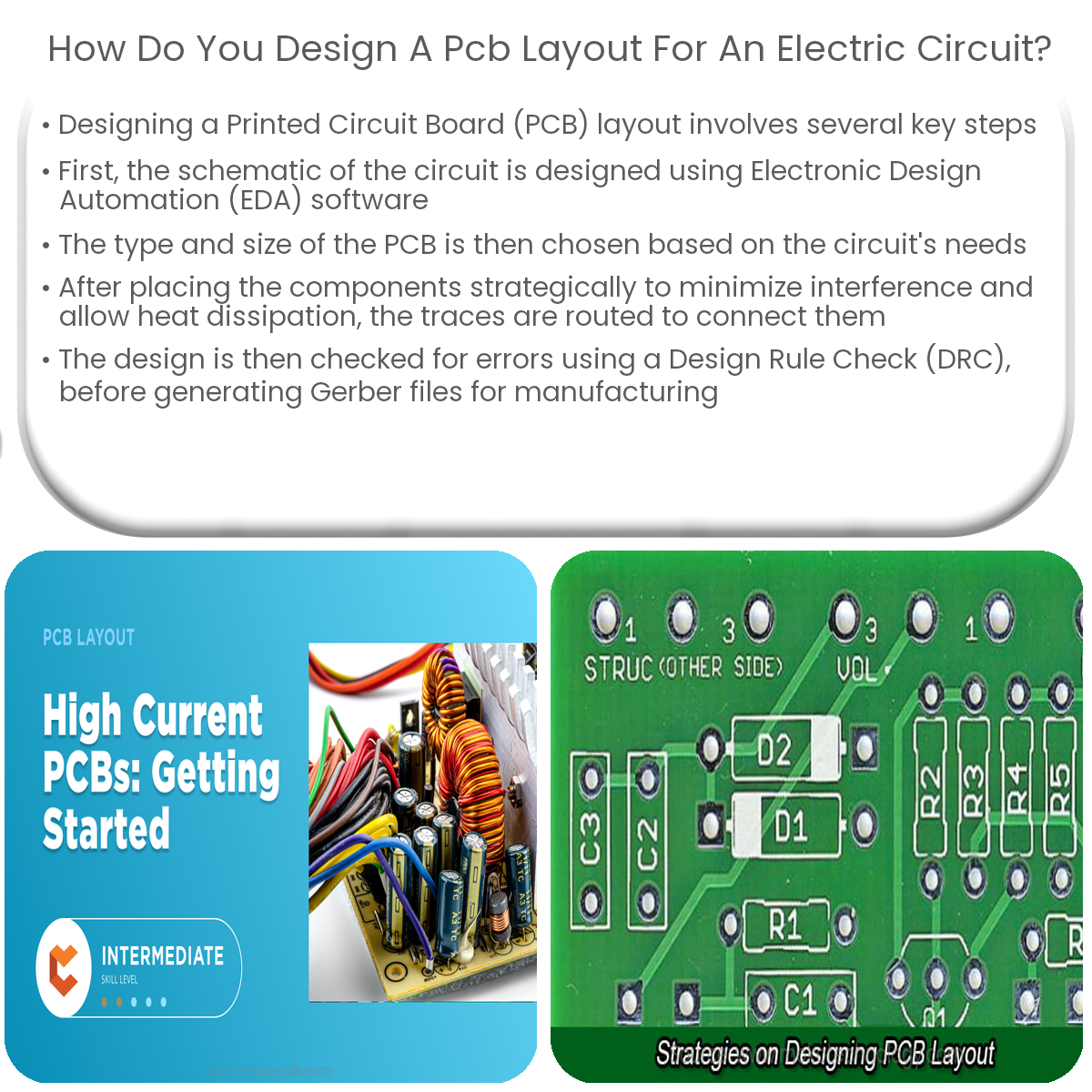

Printed Circuit Boards (PCBs) are an essential component of electronic devices, providing a platform for components and connections. This article will guide you through the process of designing a PCB layout for an electric circuit.

Step 1: Design the Schematic

Before creating the PCB layout, you need to design the schematic for your circuit. This involves selecting components and defining their connections. Use electronic design automation (EDA) software to create your schematic and ensure that it meets your requirements.

Step 2: Choose the PCB Type and Size

Next, determine the appropriate PCB type and size. Single-layer PCBs have a single conductive layer, while double-sided and multilayer PCBs provide more complexity. Consider your circuit’s needs and constraints when choosing the size and type.

Step 3: Component Placement

-

Begin by placing larger components, such as connectors and power supplies, which may have fixed locations.

-

Place analog and digital components in separate areas to minimize interference.

-

Arrange components logically, grouping those with similar functions or connections.

-

Ensure sufficient spacing between components to allow for heat dissipation and future maintenance.

Step 4: Routing the Traces

Once components are placed, route the traces to connect them. Consider the following tips:

-

Keep trace lengths as short as possible to minimize signal degradation and interference.

-

Use wider traces for high-current paths and narrow traces for low-current signals.

-

Keep traces parallel to each other and use 45-degree angles instead of 90-degree angles to reduce electromagnetic interference.

-

For double-sided or multilayer PCBs, use vias to connect traces on different layers.

Step 5: Adding Ground and Power Planes

Ground and power planes help distribute current evenly and provide a stable reference voltage. For multilayer PCBs, dedicate one layer to the ground plane and another to the power plane. For single-layer or double-sided PCBs, use a ground pour, filling empty spaces with copper connected to the ground.

Step 6: Design Rule Check (DRC)

Perform a design rule check (DRC) using your EDA software to identify potential errors or violations of manufacturing constraints. Fix any issues and recheck the design.

Step 7: Generate Gerber Files

Once your layout is finalized, generate Gerber files, which provide manufacturing specifications for your PCB. Review these files and send them to your PCB manufacturer.

In conclusion, designing a PCB layout involves creating a schematic, selecting components, placing them on the board, routing traces, and checking the design before generating manufacturing files. By following these steps, you can create a functional and reliable electric circuit.