Explore the world of high voltage insulators – their function, types, materials, modern challenges, and role in renewable energy.

Understanding High Voltage Insulators

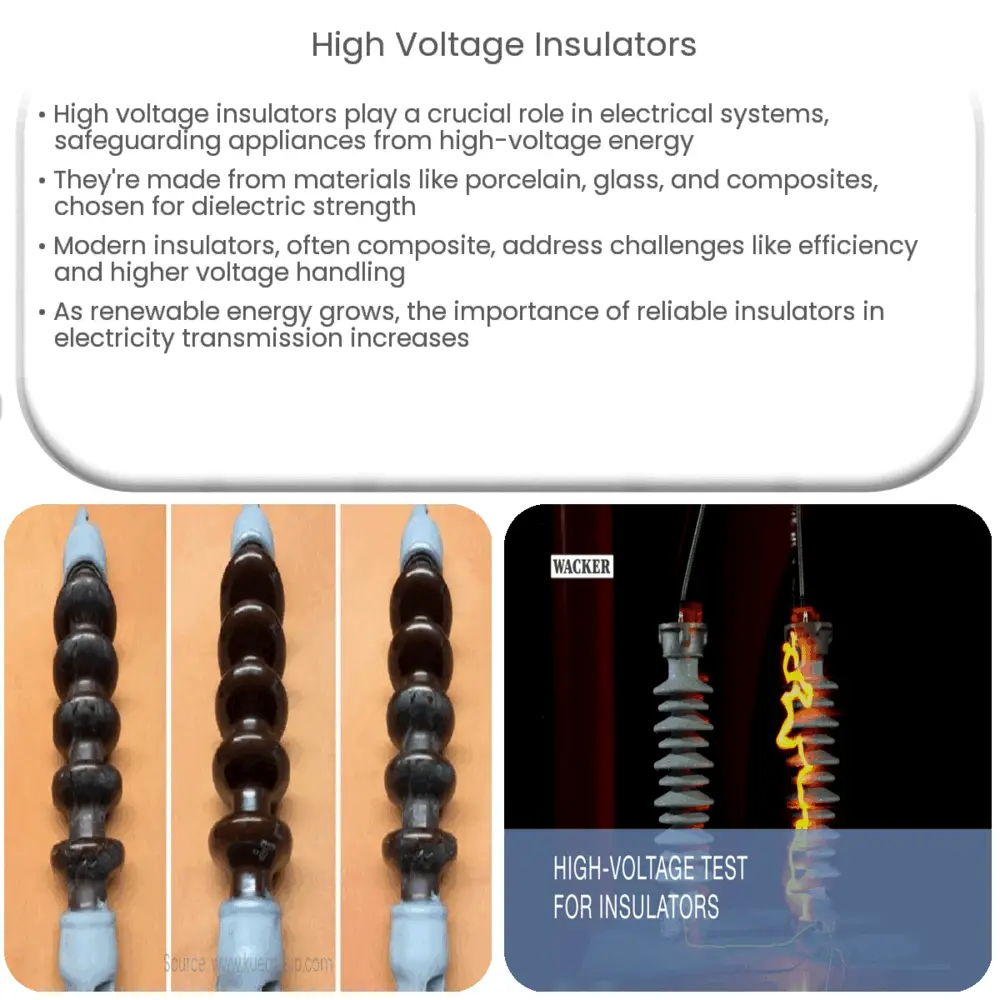

The realm of electrical engineering is rich with various components that play crucial roles in our everyday lives. One such essential component in electrical systems, often unnoticed but serving a vital purpose, is the ‘High Voltage Insulator’. This part of the system safeguards us and our appliances from high-voltage electrical energy.

The Function of High Voltage Insulators

High voltage insulators are engineered to withstand and isolate high voltages, preventing electrical energy from unintentionally escaping the designed path. They’re commonly used in electrical power transmission and distribution systems, railways, substations, and other areas where high voltage is required.

Material Composition

The choice of materials used in the manufacture of high voltage insulators is imperative. These materials are often selected for their high dielectric strength – the maximum electric field a material can withstand without breaking down. Some common materials include:

- Porcelain: Traditionally, porcelain has been a popular choice due to its good mechanical strength and high dielectric properties. Porcelain insulators are produced from clay, quartz or alumina, and feldspar, and are covered with a smooth glaze to shed water.

- Glass: Glass insulators have a lower mechanical strength than porcelain but exhibit very high dielectric properties. They are also transparent, making internal defects easy to identify.

- Composite Materials: These are newer materials being utilized due to their high dielectric strength, lower weight, and resistance to pollution. They are typically made from silicon rubber or epoxy resins.

Types of High Voltage Insulators

High voltage insulators come in a variety of designs, each suited to its specific role within the electrical power system. Some commonly used types include:

- Pin Insulators: These are the earliest type of insulator and are generally used for voltages up to 33kV. They are shaped like a spinning top and mounted vertically.

- Suspension Insulators: For voltages greater than 33kV, suspension insulators are typically used. They consist of a number of glass or porcelain discs connected in series.

- Post Insulators: Post insulators are designed to carry heavy loads and are commonly found in substations and switchgear.

Modern Developments and Challenges

In recent years, advancements in material science and electrical engineering have led to the development of improved high voltage insulators. These advancements are primarily driven by the need for better efficiency, durability, and the capacity to handle higher voltages. Modern insulators tend to use composite materials that can provide higher resistance to electrical breakdown, better performance in polluted environments, and lighter weight.

However, these developments also come with their own set of challenges. Issues such as ageing of the material, contamination, and tracking are some of the problems that engineers must tackle. Moreover, the reliability of these insulators in different weather conditions and long-term performance are also areas of concern.

Maintenance of High Voltage Insulators

Maintenance is crucial for the longevity and performance of high voltage insulators. Insulators can accumulate dirt, salt, pollution and other contaminants, which can decrease their insulating properties and lead to flashovers. Regular cleaning and inspection are necessary to prevent this. Furthermore, insulators should be replaced periodically according to their lifespan to maintain the reliability of the power system.

The Role of High Voltage Insulators in Renewable Energy

As the world moves towards renewable energy, the demand for efficient and reliable high voltage insulators has increased. These insulators play a critical role in the transmission and distribution of electricity generated from renewable sources like solar and wind power. Thus, ensuring the design and material quality of these insulators is key for the success of renewable energy initiatives.

Conclusion

In conclusion, high voltage insulators are fundamental components in our electrical systems. Their role in managing and isolating high voltage electricity is crucial for the safety and efficiency of power transmission and distribution networks. With advancements in material science and engineering, modern insulators are being designed to handle more complex challenges. As the world leans more towards renewable energy, the role of high voltage insulators becomes even more vital. Therefore, understanding their functionality, types, materials, and the challenges they face is key to appreciating their indispensable role in our electricity-dependent world.