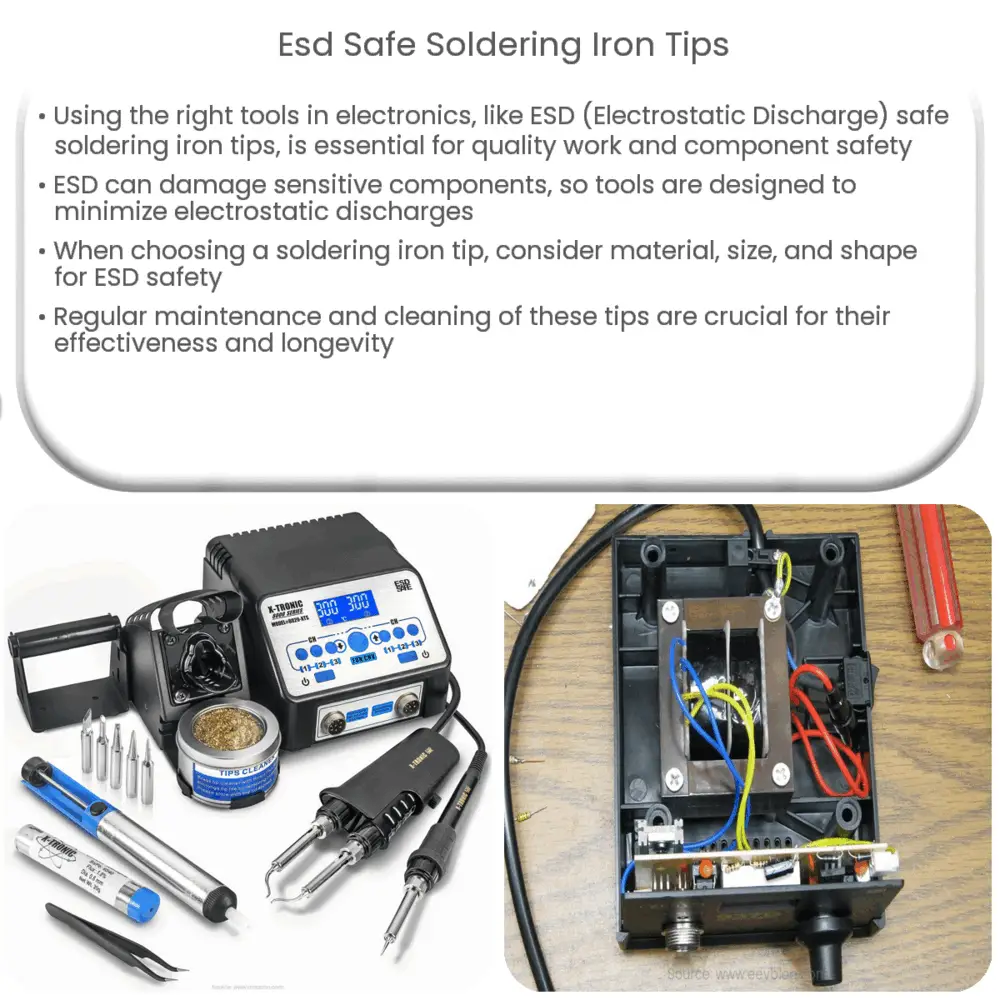

Explore the importance of ESD safe soldering iron tips, learn how to choose one, and understand their maintenance for efficient soldering.

Understanding ESD Safe Soldering Iron Tips

Whether you are a seasoned electronics repair professional or an enthusiast, you undoubtedly understand the importance of using the right tools for any job. One essential tool for working with electronic components is the soldering iron. But not just any soldering iron will do; it should be ESD (Electrostatic Discharge) safe. In particular, the soldering iron tip plays a crucial role in maintaining ESD safety. In this article, we explore ESD safe soldering iron tips, their importance, and factors to consider when selecting one.

What Does ESD Safe Mean?

ESD refers to the sudden flow of electricity between two electrically charged objects. This can happen due to contact, an electrical short, or dielectric breakdown. In electronics, ESD can cause damage to sensitive components, sometimes causing irreversible harm. An ESD safe tool, such as a soldering iron tip, is designed to prevent such damage by minimizing the possibility of creating a damaging electrostatic discharge.

Why Use ESD Safe Soldering Iron Tips?

Soldering irons, by their very nature, create a lot of heat. If not managed correctly, this heat can build up an electrostatic charge. When the charge builds up sufficiently, it can discharge into the component being soldered, potentially causing damage. The use of an ESD safe soldering iron tip is critical in preventing such occurrences.

Key Factors in Choosing ESD Safe Soldering Iron Tips

- Material: The material used to make the soldering iron tip plays a significant role in its ESD safety. Look for materials like copper, which is an excellent heat conductor and is also good at grounding any potential charge.

- Size: The size of the soldering iron tip is crucial. It should match the work you plan to do. Larger tips store more heat and are great for larger components, but can increase the chance of ESD. Smaller tips, on the other hand, are suitable for precision work on smaller components.

- Shape: The shape of the tip affects how heat is transferred to the component. There are many shapes available, each designed for a specific type of soldering work.

Choosing an ESD safe soldering iron tip is about more than just the specs, though. It’s about protecting your components from damage while making your work easier and more efficient.

Understanding the Different Shapes of Soldering Iron Tips

The shape of a soldering iron tip greatly influences the heat transfer process during soldering. Different shapes serve various purposes, and choosing the right one can significantly impact the quality of your work. Here are some common tip shapes and their applications:

- Conical tips: These are pointed tips that are perfect for precision tasks and small components. The fine point allows for a concentrated heat application but is not ideal for larger components or heavy-duty soldering.

- Chisel tips: As the name suggests, these have a flat end resembling a chisel. Chisel tips are excellent for larger components and thicker wires because they can store and transfer more heat than conical tips.

- Bevel tips: Also known as hoof tips, these are particularly useful for surface mount components and allow for a good amount of heat transfer. The flat surface can be used for larger components, while the point can work on smaller parts.

Maintaining ESD Safe Soldering Iron Tips

Even the best ESD safe soldering iron tips require regular care and maintenance to keep them at their best. Regular cleaning is essential as oxidation and solder residue can build up on the tip, impeding heat transfer and potentially leading to ESD. Proper storage is also critical. When not in use, tips should be stored in a dry, dust-free environment to prevent damage or corrosion.

Conclusion

In conclusion, ESD safe soldering iron tips are an indispensable tool for anyone working with electronic components. They provide the assurance that you are doing everything you can to protect sensitive components from potential ESD damage. By understanding the importance of ESD safety, the various factors influencing the selection of soldering iron tips, and the need for their proper maintenance, you can ensure your work’s quality and longevity. Remember, the right tool isn’t just about getting the job done; it’s about getting it done right.