Explore the importance of ESD safe packaging materials in preventing damage to electronic devices and best handling practices.

Understanding ESD Safe Packaging Materials

Electrostatic Discharge (ESD) safe packaging materials are an integral part of a wide array of industries, especially in electronics and sensitive equipment manufacturing. This kind of packaging is designed to protect electronic devices that are prone to damage by electrostatic discharge or ESD. Understanding what ESD safe packaging materials are and their importance is fundamental to the integrity of sensitive electronic components.

What is ESD?

ESD, or Electrostatic Discharge, is essentially a sudden flow of electricity between two electrically charged objects. This situation is typically caused by contact, an electrical short, or dielectric breakdown. A buildup of static electricity can be caused by tribocharging or by electrostatic induction.

The Need for ESD Safe Packaging Materials

The microcircuitry in modern electronic devices is susceptible to damage from static electricity. Without adequate protection, the static charge generated by ordinary handling can reach up to thousands of volts. When this static electricity is discharged onto an electronic device, it can cause immediate damage or latent defects.

- Immediate Damage: This type of ESD damage is typically catastrophic, causing the device to stop functioning immediately. It is easy to detect but can lead to significant loss in terms of damaged goods.

- Latent Defects: Latent damage can significantly degrade the performance of the device over time, potentially leading to premature failure. These defects are hard to detect, often going unnoticed until the device fails in the field.

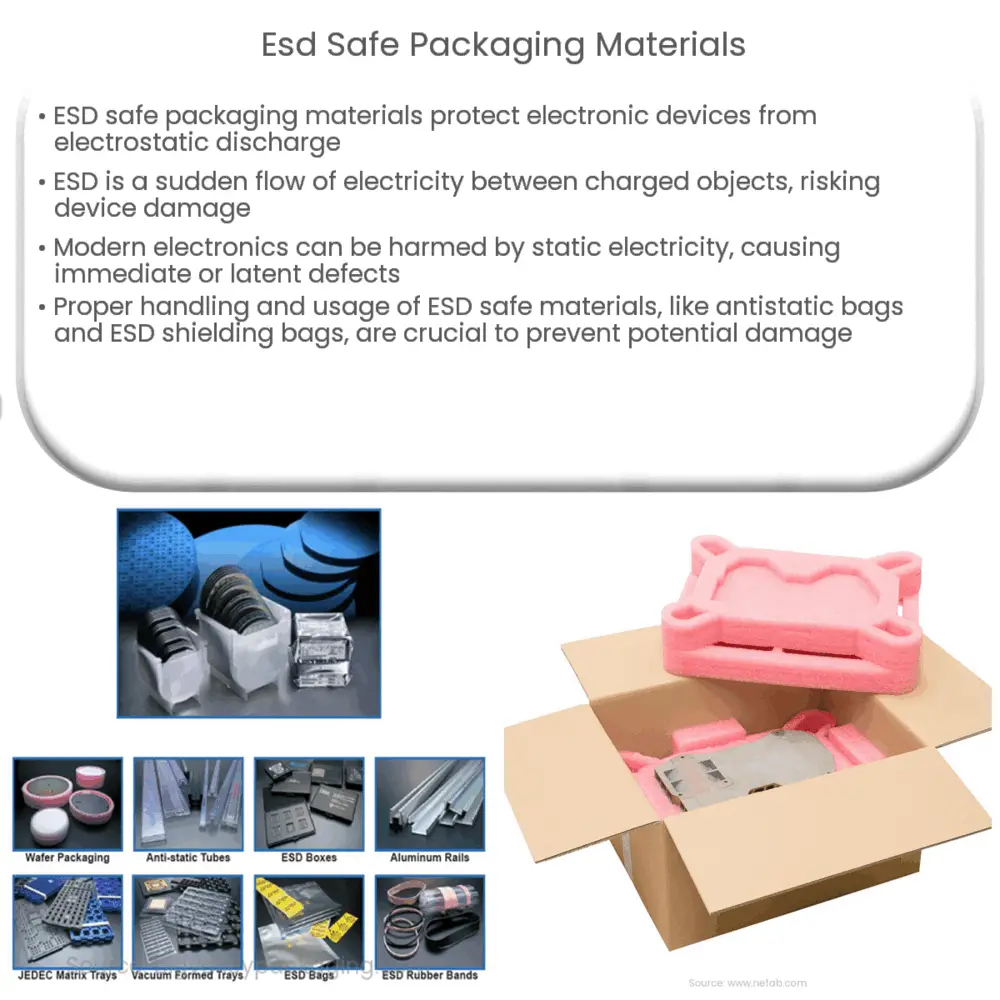

Types of ESD Safe Packaging Materials

Several types of ESD safe packaging materials are used to protect sensitive electronic components from static electricity. Here are a few of the most commonly used:

- Antistatic Bags: These bags are typically coated with a conductive material, reducing the amount of static electricity they generate. They also prevent the contents from generating a static charge.

- Conductive Boxes and Bins: These containers are made from materials that conduct electricity, eliminating the chance of a static charge building up on the surface of the box.

- ESD Foam: This foam can be used to line the interior of boxes and bins, providing additional protection against static charges.

ESD Shielding Bags

In addition to the previously mentioned packaging options, ESD Shielding Bags are another highly effective type of ESD safe packaging material. These bags offer a protective shield against ESD, reducing the potential risk of electrostatic discharge.

- ESD Shielding Bags: These bags create a Faraday cage effect, which shields electronic devices from static charges. Shielding bags are usually made of a static dissipative polyethylene terephthalate (PET) outer layer, a conductive aluminum shielding middle layer, and an antistatic inner layer.

ESD Safe Packaging Practices

Merely investing in ESD safe packaging materials isn’t enough. Proper use and handling of these materials are essential for full protection. Here are some practices to follow:

- Training: All staff handling sensitive electronics should be trained in ESD safe handling procedures.

- Environment: The environment should be controlled for static electricity. This can include the use of ESD mats and grounding straps.

- Packaging Selection: The packaging material chosen must be suitable for the specific device being packed. Not all devices require the same level of protection.

- Labeling: Packages should be clearly labeled to indicate that they contain ESD sensitive devices, thus ensuring proper handling.

Conclusion

In conclusion, ESD safe packaging materials play a crucial role in preventing damage to electronic devices caused by Electrostatic Discharge. Various types of ESD safe materials, including antistatic bags, conductive boxes and bins, ESD foam, and ESD shielding bags, are available to cater to different needs. However, proper usage and implementation of these materials are as important as the materials themselves. By following best practices and ensuring that all staff are trained in handling these materials, companies can reduce the potential risk of ESD damage, thereby ensuring the longevity and reliability of their electronic products.