Discover the importance, types, and application of ESD safe labels in electronics manufacturing, ensuring ESD protection and compliance.

Understanding ESD Safe Labels

Electrostatic discharge (ESD) safe labels play an essential role in preventing ESD-related damages in electronics manufacturing and assembly industries. They contribute significantly to the overall ESD control program by ensuring traceability and protection of electrostatic-sensitive devices (ESDs).

The Importance of ESD Safe Labels

ESD can cause severe damages, such as equipment malfunction or complete device failure. The key to preventing such situations lies in an effective ESD protection strategy, and ESD safe labels form a vital component of this strategy.

- Protection: ESD safe labels provide critical protection for sensitive electronic components. They help identify and segregate ESD sensitive items, thereby preventing inadvertent damages.

- Compliance: Most electronics manufacturing industries follow stringent ESD control standards. ESD safe labels ensure that these components are compliant with the necessary regulations, thereby helping to avoid regulatory complications.

- Traceability: These labels offer a convenient method for tracking and tracing ESD sensitive components throughout the supply chain, thus ensuring their safe handling and transportation.

Types of ESD Safe Labels

There are several types of ESD safe labels available in the market, each designed to suit specific requirements and applications.

- Permanent ESD Attention Labels: These are non-removable labels used for permanent identification. They are generally used for containers or products that always need ESD caution.

- Removable ESD Attention Labels: These labels can be easily removed without leaving a residue. They are ideal for temporary identification of ESD sensitive items.

- Anti-static Labels: These labels are made of material that does not generate static electricity. They are used for items that need to be kept in an ESD protected area (EPA).

The choice of the right ESD safe label type depends on the specific needs of your business, the nature of the ESD sensitive devices you handle, and the regulations that you need to comply with.

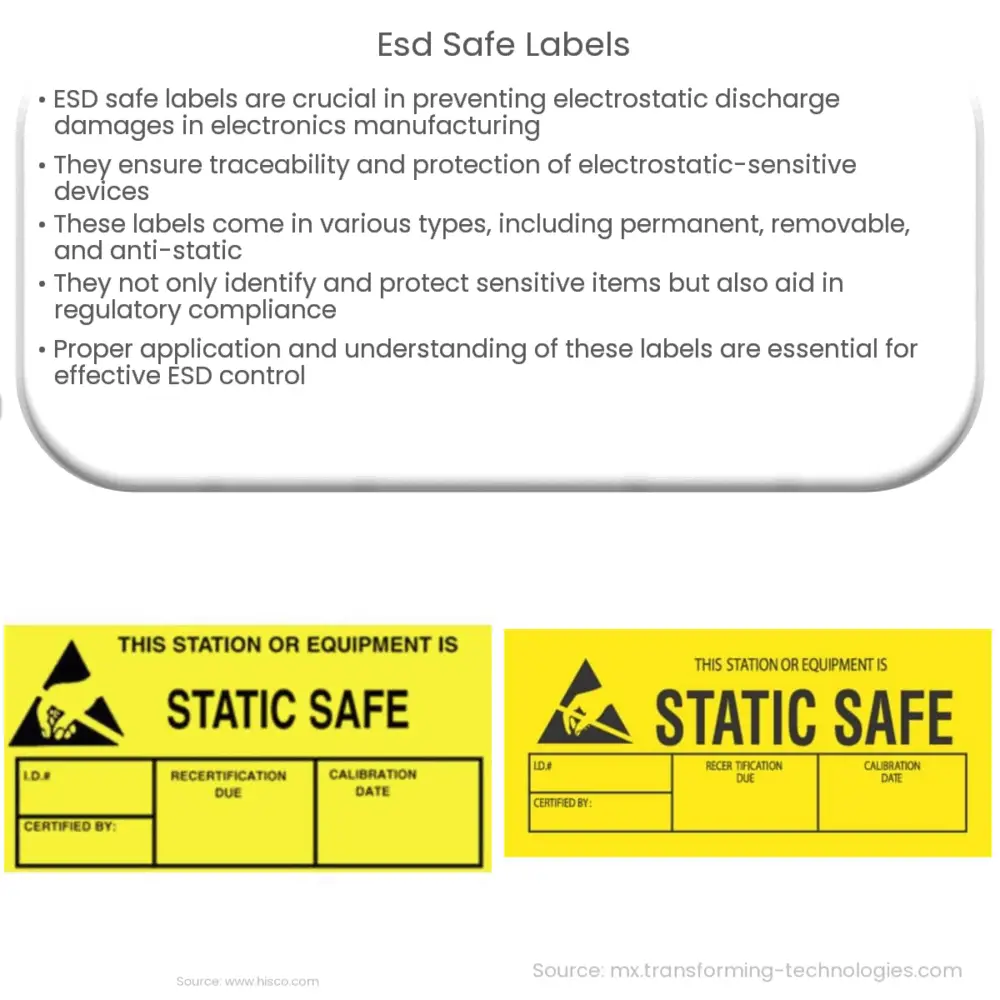

Components of ESD Safe Labels

The main components of an ESD safe label are the ESD symbol and the text. The symbol typically consists of a hand in the act of reaching, enclosed within a triangle, indicating that the device is susceptible to ESD damage. The text provides additional cautionary or informative details, such as the sensitivity level of the device, handling instructions, and other relevant information. The use of bothsymbol and text is essential to ensure the label’s effectiveness.

Choosing the Right ESD Safe Labels

Picking the right ESD safe label for your needs involves considering various factors. Here are a few guidelines to help you make an informed decision:

- ESD Sensitivity of Components: The first consideration should be the ESD sensitivity level of your components. The higher the sensitivity, the more protective the label needs to be.

- Regulatory Compliance: Consider the regulations that your industry must comply with. ESD control standards like IEC 61340-5-1 require specific types of labels.

- Environment: The working environment is a key determinant in choosing ESD safe labels. For example, a high-temperature environment might require labels with heat-resistant properties.

Application of ESD Safe Labels

Applying ESD safe labels should be a part of a comprehensive ESD control plan. Labels should be used on ESD sensitive items, containers, and areas to effectively prevent ESD damage. However, it’s important to remember that the mere presence of labels is not enough. They must be accompanied by other ESD control measures like using ESD safe workstations, tools, packaging, and following ESD control procedures.

Conclusion

ESD safe labels are indispensable tools in the electronics industry. They provide an essential line of defense against electrostatic discharge, which can cause catastrophic damage to sensitive components. By ensuring the traceability, protection, and regulatory compliance of ESD sensitive items, these labels play a vital role in maintaining the quality and reliability of electronic products. However, their effectiveness largely depends on their correct usage as part of a comprehensive ESD control program. So, understanding the various types of ESD safe labels, their components, and their correct application is crucial for any business dealing with ESD sensitive devices.